About almaak

almaak has 60 years of experience in the production of recyclates. This extensive experience in handling secondary raw materials makes the company one of the leading providers of sustainable product solutions in Europe. Due to the good availability as well as the high quality and consistent material sources, only post-industrial recyclates (PIR) were used as raw materials for these products for a long time. Since the end of 2023, the first products with a share of post-consumer recyclates (PCR) are available.

The problem: Highly contaminated regrind

The plastics processing industry must constantly face growing demands: rising raw material prices, lack of material availability, complicated supply chains, increased delivery times, but above all, continuously decreasing material quality in the form of contamination with foreign bodies, foreign colors, and foreign plastics. The most important requirement from almaak: Metal particles should be removed from the regrind with minimal loss of good material.

The solution: Material sorting with the PRE-SORT VCM sorting platform

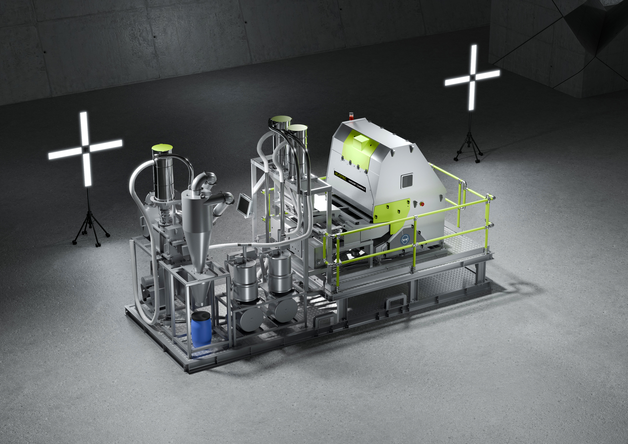

In order to produce sustainably and with process reliability using PCR, plastic processors must be able to control the quality of their incoming material themselves. Contaminants such as metal particles impair the quality of plastics. The goal is to increase the purity of the material before processing to automatically ensure more safety and higher quality of the end products. With the PRE-SORT sorting platform from Sesotec, almaak has full control over the quality of the incoming material and becomes more independent from external suppliers. Thanks to freely combinable sensors and the ability to select various sorting processes depending on the material composition, the mobile sorting platform offers full process flexibility. Following the idea of a plug-and-play methodology, the system is ready for immediate use and seamlessly integrates into any production environment thanks to its compact design.

.JPG)

.JPG)

The device makes it possible to purchase goods in B or C quality at a lower price, which means savings of up to 50% compared to A quality. The PRE-SORT sorting platform pays for itself within a short period of time.

The customer benefit: Pure regrind with the highest quality and minimal loss of good material.

The advantages of material pre-sorting with PRE-SORT are obvious: high-quality and pure material, economical production, and protection against damage to subsequent equipment.

“With trials in August 2023, Sesotec has shown us that our requirements can be met in practice. Metal particles were removed from the regrind, and the loss of good material was minimal,” says Marc Marmetschke, Senior Manager Engineering, Maintenance and Project-Development at almaak. He adds: “Our short-term goal is the demetallization of several hundred tons of heavily contaminated material that has been in our warehouse for some time so that we can use the material. This will allow us to benefit from an immediate return on investment."

Download this case study as a document.