If contaminated recyclate is used in plastic production and processing, it reduces product quality and may even damage machines. The solution is systems that reliably detect contaminants and correctly sort the material.

Recycled material recovered from used plastic is a valuable material that is fed into the production of new products. Manufacturers and processors use it in the form of flakes, powder or granulate. Provided, of course, that the quality is right. Because differing types of plastic, incorrect colors or foreign objects can significantly impair the quality of the recycled material. Contaminants in recycled materials can thus be roughly divided into three classes: foreign plastics, incorrect colors and foreign objects.

Such contaminants can enter the material flow at almost every stage of the circular economy. All sorts of materials that do not belong there can already be found in the baled plastic waste from collection systems. To ensure the quality of the recycled materials, recycling companies must carefully sort plastic waste. According to samples, the share of contaminants in plastic waste is around 80 percent.

If the contaminants remain undiscovered, they leave traces in the recycled products. The consequence is complaints, which means more effort for the manufacturers. In cases where the contaminants are foreign bodies made of metal, they can even cause damage to the production machines. This results in significant costs for the plastic processing companies.

Detect material and plastic types with near-infrared sensors

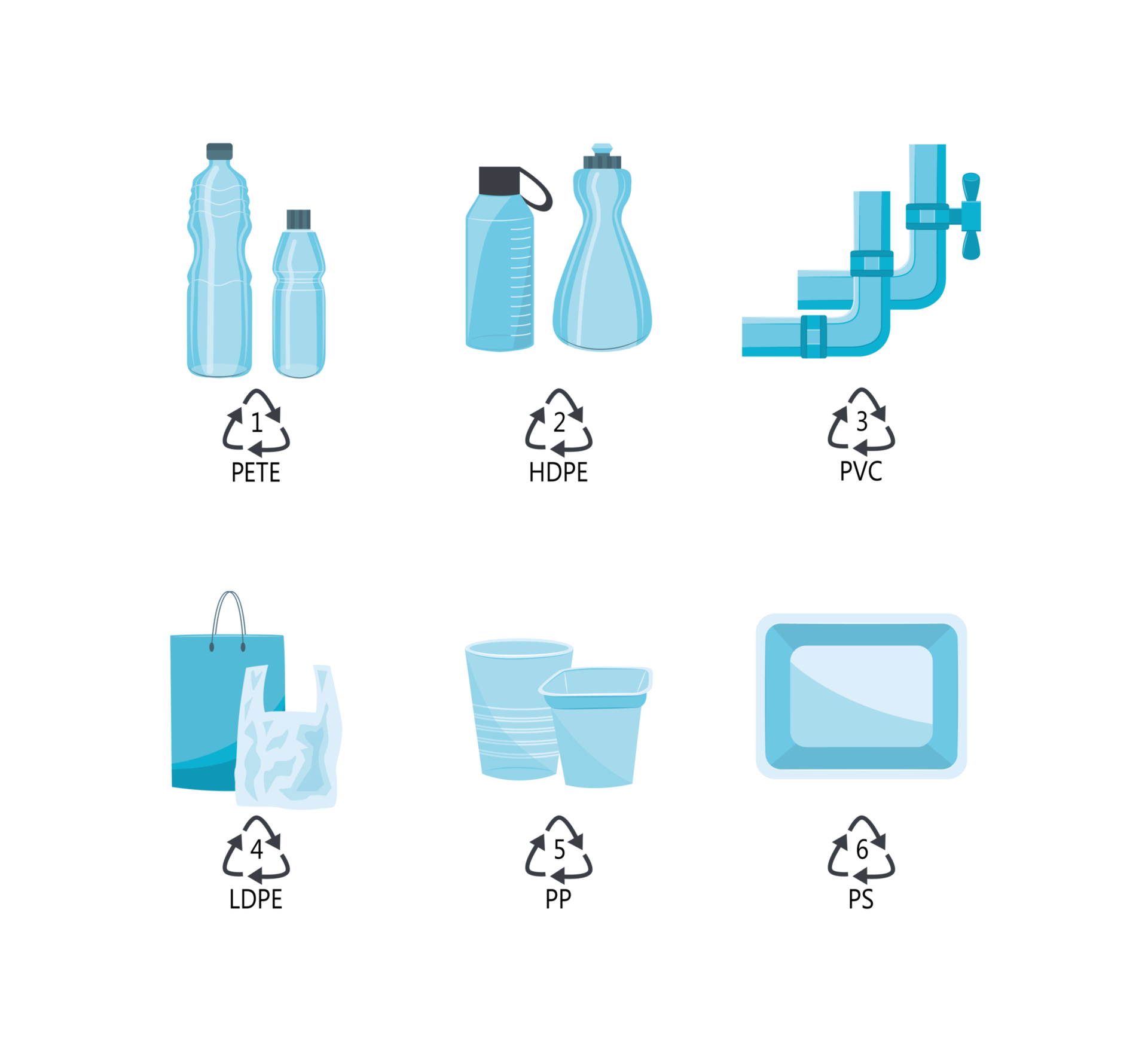

Separating different types of plastics from each other is one of the most challenging tasks in the recycling process. This is because the collected plastic remnants often consist of a composite of different materials. An example is plastic tabs made of polyethylene terephthalate (PET), which are generally easy to recycle. However, the closure of these PET bottles is often made from another material – for example, polyethylene (PE) or polypropylene (PP). These plastics have different properties from PET and cannot be recycled in the same way. The label on bottles can also be made from a different plastic. The same problem occurs with sausage or cheese packaging. Often, the tray and the sealing film are made of different plastics.

A pure collection that divides plastics into their various types does not usually exist. Consumers would be overwhelmed by this task anyway. For this reason, manufacturers of recyclate rely on powerful sorting systems. They reliably differentiate between materials. Using near-infrared sensor technology, they sort into uniform fractions. Even contaminants, such as stones, are detected by the near-infrared sensors.

Camera sensors for color detection

In the same sorting systems, color recognition sensors are also installed. This is because flakes or granules of recycled material should not only have the same properties but also look alike. However, producing recycled material in a uniform color is challenging. The colorful label on a plastic bottle can already lead to unsightly defects in the new product. Who wants a white housing of an electrical device with gray streaks because the recycled material used contained off-colors? Systems equipped with camera sensors can detect and sort out the inappropriately colored particles. Infrared sensors combined with color sensors, for example, determine whether PET bottles are made of transparent or colored material.

Separate metal using magnets and inductive sensors.

Foreign objects form the third group of contaminants. Metal particles are one of the most common causes of contaminated recyclate. These can be clips, nails, or other tiny items. Although they are barely noticeable, they can cause significant damage. Metallic foreign objects enter plastic waste at all stages of the circular economy – for example, through misplacement and incorrect sorting. Countermeasures include inductive metal detectors and magnetic systems that identify and remove these foreign objects.

Another cause of foreign objects in recyclate can be the shredding process. In this section, machines shred plastic remnants to later sort the individual pieces. However, the blades of the shredding machines wear down over time. Metal residues then enter the recyclate and thus the subsequent manufacturing process. During the production of the recyclate, they are melted and enclosed. When the contaminated recyclate is processed in this way, the invisible metal particles can unexpectedly cause damage to the manufacturing machines and lead to long downtimes. They must therefore be safely removed from the system. This is possible if magnets and/or inductive metal detectors/separators are installed in conveying lines and on processing machines.

The entire process in view

With coordinated sorting, manufacturing, and processing procedures, particularly good results can be achieved. The pre-sorted plastic waste, mostly pressed in bales, is examined for contaminants after being dissolved, ground, and the flakes are intensively washed. Afterwards, the flakes undergo further sorting. When both sorting systems come from the same provider, overall performance can often be improved. Service is also reflected in lower costs.

Ultimately, the entire process is about producing a recycled material that can be used appropriately. New food packaging can be created from particularly high-quality material. Materials that do not meet these "Food Grade" requirements can be used in fiber production or as packaging or insulation material.

Product design influences recyclability

Sorting machines could work even more thoroughly if the composition of plastic products facilitated recycling. So far, that is rarely the case. Developers are instead optimizing materials and products – with regard to their respective intended use and because they expect better market prospects. One example is black plastic bottles, which look modern and are therefore well-sold to certain target groups. However, the material used cannot be sorted well due to its light-absorbing properties. Black plastics, therefore, often end up in incineration.

To create a recycling-friendly product design, manufacturers must adhere to rules. For example, it is advantageous to use only one type of plastic instead of composite materials. If several material layers are needed, they should be easily separable. It is also helpful to provide consumers with an indication to separate the components of the packaging, such as by removing labels before disposal. Of course, it is best if the labels are made of the same material as the package.

So far, it is mostly individual eco-friendly providers who consciously focus on a sustainable product design. Legislators, however, are only slowly becoming active. “Regulations for a recycling-friendly product design are the exception,” says Michael Perl, Group Director Sorting Recycling at Sesotec. “In addition, incentives need to be created to promote the use of recyclates as a pure secondary material in plastic production.”

Bartosch Jauernik, Product Manager Plastics at Sesotec, admits that durability and good functional properties are important to sell a product on the market. “However, recyclability should be given the same priority and be integrated into product development from the start. In addition, the use of recyclate, as proposed by the Resources Commission at the Federal Environment Agency, could be made mandatory through a so-called substitution rate.” The substitution rate indicates which amounts of primary raw materials should be specifically replaced by secondary raw materials or recyclates. Thus, the aim of the substitution rate would be not only a new assessment of recycling success but ultimately also the mandatory rate of recyclates used in products.

However, the will and readiness of the entire chain – from legislators to manufacturers and retailers to consumers – are also necessary to achieve sustainability, regardless of temporary influencing factors such as price developments.