Until 2016, RE-GLASS Kft., headquartered in Orosháza with additional locations in Budapest and Mezőörs, processed seven to eight thousand tons of flat glass per year. The production of bottle glass amounted to only one to three tons per year due to the lack of modern technology. Since only white glass was produced in Hungary, there was only a domestic market for flat and packaging glass. The collected and processed mixed packaging glass was exported as mix glass.

In 2016, Mátyás Máthé became the new owner of RE-GLASS. He is supported by Ferenc Aszódi as managing director. The decisive reason for purchasing RE-GLASS was that Hungary lagged behind the EU-wide average and standards in collecting and recycling glass waste.

The Hungarian government has begun planning to introduce a deposit system for packaging glass in 2023, which is intended to ensure compliance with EU expectations. This would also prevent this material stream from ending up in landfills.

The solution: Sorting systems for the recovery of high-quality, pure glass materials.

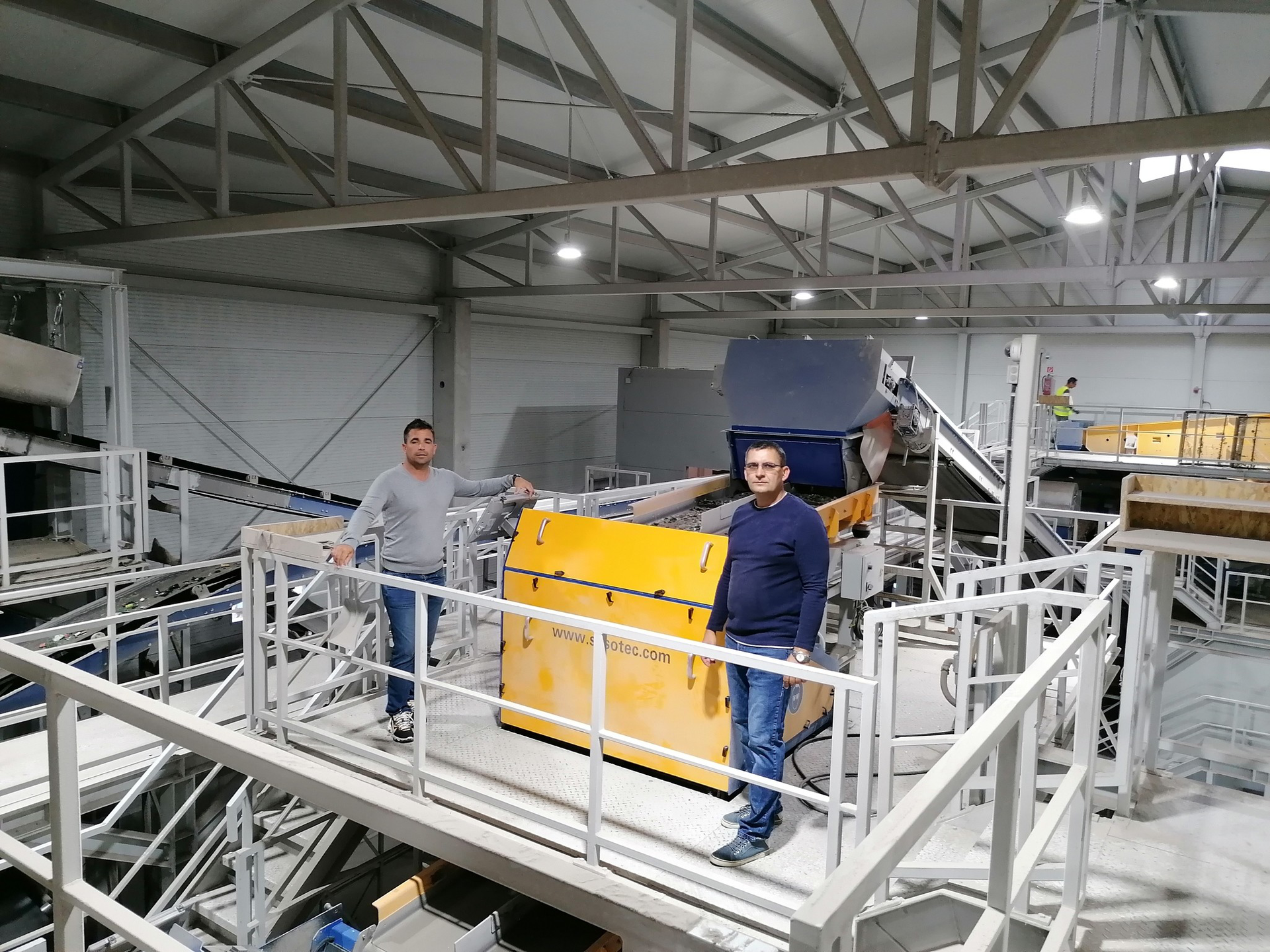

In 2018, Mátyás Máthé and Ferenc Aszódi visited the IFAT in Munich. There, they met several providers of sorting technologies before deciding on KRS GmbH, a partner company of Sesotec GmbH. In collaboration with KRS, RE-GLASS has now built the most advanced plant for sorting and processing bottle glass in Hungary, capable of processing eight to ten tons per hour.

Contaminants in the glass material posed the greatest challenge for the new plant. Impurities such as ceramics, stones, porcelain (CSP), metals, paper, and plastics make up to 15 to 20 percent of the total weight of all collected glass waste. To meet this challenge, KRS provided a sorting system that meets these requirements:

Four SPEKTRUM separation systems are connected in the line. They separate contaminants such as magnetic and non-magnetic metals, CSP, opaque plastics, and special glasses and sort the mixed glass waste by color. The result is contaminant-free and color-pure glass streams.

The plant was commissioned in October 2019. Less than a year later, in 2020, an additional 600 square meter hall was added, housing new equipment. Around the hall is an approximately 3,500 square meter paved area with an 800 square meter covered and 600 square meter open storage area. Hungarian companies, in close collaboration with KRS, built the supporting structure of the halls, manufactured and installed the conveyors and electrical wiring, and also built the PLC control for the entire production plant.

In September 2020, a successful trial run took place, during which KRS specialists set up the sorting systems and installed the Sesotec software VISUDESK. With VISUDESK, it is possible to remotely monitor the four SPEKTRUM sorters, make fine adjustments, and track error messages. This way, KRS can check the settings and provide remote support if needed.

The customer benefit: Increase in quantity, quality, and profitability.

The technology provided by KRS and Sesotec makes it possible to produce high-quality recycled glass shards, which are the perfect product for reuse in the glass industry.

“The color sorting technology has helped us increase the amount of white glass we produce for the domestic market,” says Mátyás Máthé, owner of RE-GLASS. “At the same time, our mixed glass exports now contain a lower proportion of white glass. The processing quality and quantity have also increased. We hope that our government will introduce a deposit system as announced. With a new deposit system, we can continue to operate successfully in three shifts or even transition to continuous operation with the equipment supplied by KRS.”

“Our latest technology line sorts out all foreign materials (magnetizable and non-magnetizable metals, individual paper and plastic waste). Four optical sorters are set up in a row to ensure that ceramics and wire glass are also removed from the glass waste. This results in a completely contamination-free glass product. Additionally, we sort the mixed glass waste collected by us or our partners by color. And we are able to adjust the color sorting according to our customers' requirements with an accuracy of one to two percent. One of our Hungarian partners produces glass foam from zero to six-millimeter glass shards. So you could say that the glass waste we process continues its life as a one hundred percent glass product. The circular economy is a reality, and RE-GLASS makes a significant contribution to it,” adds RE-GLASS Managing Director Ferenc Aszódi.

Download this case study as a document.