FOREIGN BODY DETECTION FOR CONFECTIONERY

Sweet. Safe. Pure.

Open processes, wooden molds, raw materials with high contamination potential: foreign bodies are practically unavoidable in confectionery production. Sesotec metal detectors and X-ray scanners reliably identify and remove these contaminants before they can damage machinery or end up in the final product, posing a risk to consumers. Additionally, our devices monitor the fill level, completeness, weight, and integrity of your products.

The Most Common Foreign Bodies in Confectionery Production

Metal Wear in Conveyor Lines

During raw material transport, fine metal dust can detach from the conveyor lines and contaminate your products.

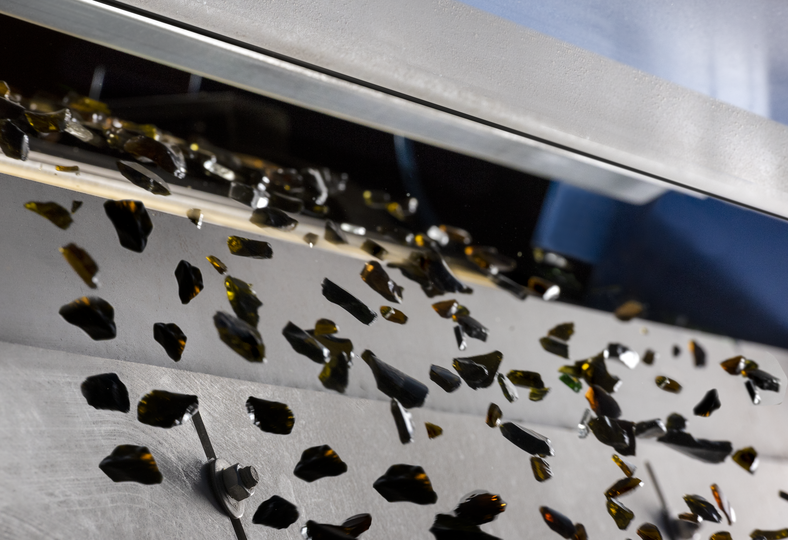

Shattered Glass

Glass shards can enter the production area through broken lights or containers.

Little Stones

Small stones often go unnoticed when mixed with raw materials like grain during the production process.

Metal Wear from Processing Machines

During continuous operation, friction can cause tiny metal shavings or particles to detach from machines and end up in the final product.

Machine Breakdown

Damage or fractures in processing machines can introduce large metal or plastic parts into the production flow.

Operator Items

Personal items like pens or screws can accidentally fall into the production line.

Metal Wear in Conveyor Lines

During raw material transport, fine metal dust can detach from the conveyor lines and contaminate your products.

Shattered Glass

Glass shards can enter the production area through broken lights or containers.

Little Stones

Small stones often go unnoticed when mixed with raw materials like grain during the production process.

Metal Wear from Processing Machines

During continuous operation, friction can cause tiny metal shavings or particles to detach from machines and end up in the final product.

Machine Breakdown

Damage or fractures in processing machines can introduce large metal or plastic parts into the production flow.

Operator Items

Personal items like pens or screws can accidentally fall into the production line.

Foreign bodies in your confectionery production?

Three Technologies, One Goal: Safe Enjoyment

- X-ray Inspection

- Metal Detection

- Magnetic Systems

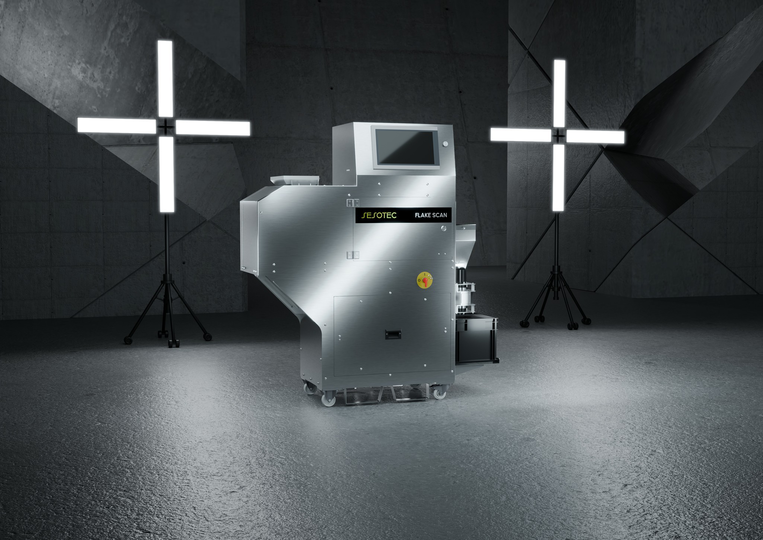

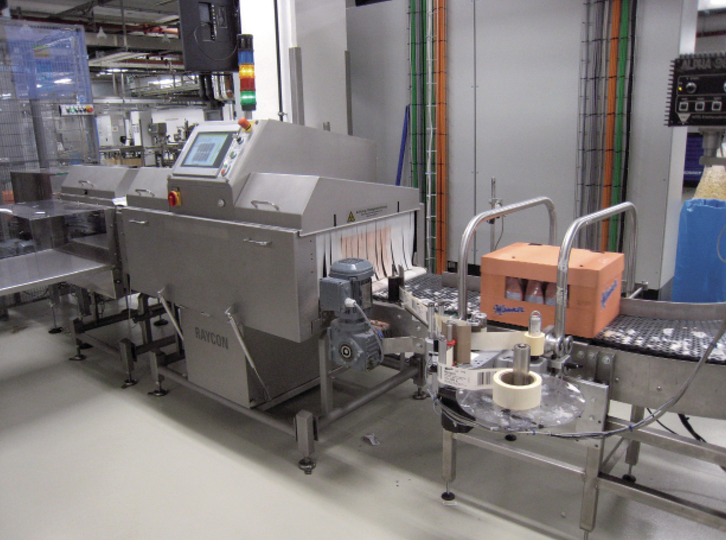

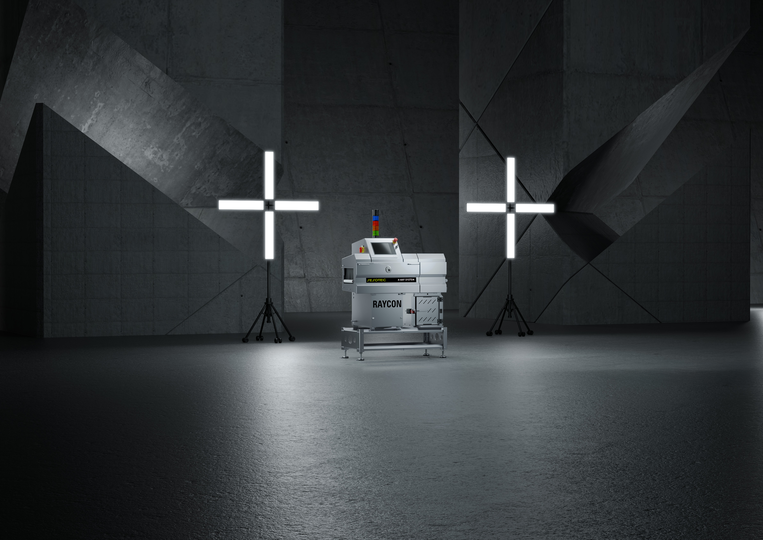

X-ray Inspection

Our X-ray inspection systems ensure precise detection of all relevant foreign bodies in confectionery production.

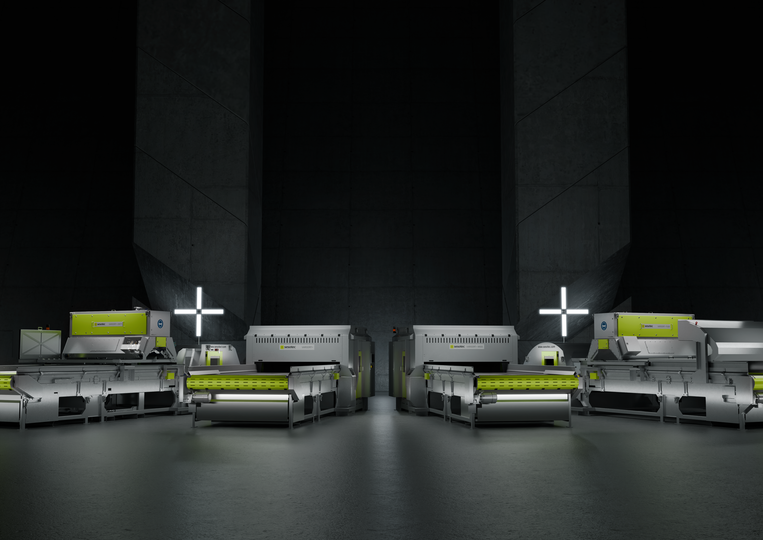

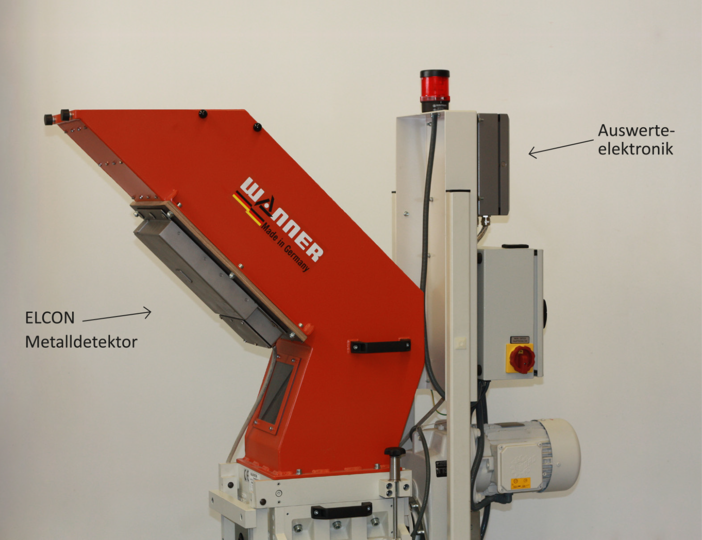

Metal Detection

Sesotec metal detection systems reliably identify metallic contaminants in confectionery.

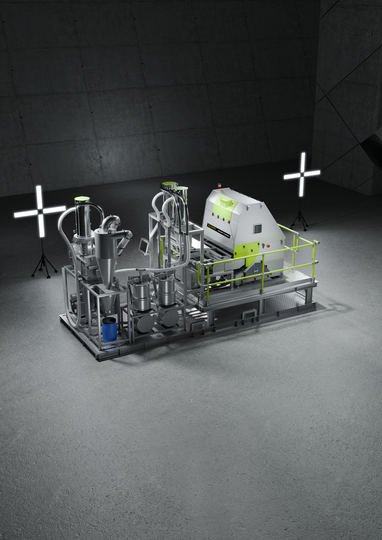

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from confectionery before further processing.

Sweet Treats? Safety First!

Sesotec's metal detectors and X-ray systems are utilized at goods receipt, final quality assurance at goods dispatch, and various production stages.

In addition to foreign body detection, Sesotec X-ray scanners can also monitor fill levels, completeness, and weight of packaged goods. They also detect broken products.

Gummy Candy

During gummy production, foreign bodies like plastic debris or metal shavings can occur.

Candies

During the manufacturing process, small foreign bodies like glass or metal fragments can enter the product from machinery.

Chocolate

Processing chocolate demands precise machinery, where metal abrasion or other foreign bodies can occur.

Bars

Snack and muesli bars undergo multiple processing stages where plastic or metal fragments can contaminate the product.

Ice

In ice production, foreign bodies like metal shavings, packaging remnants, or plastic can enter the mix.

Chocolates

Small foreign bodies like metal shavings or glass fragments can contaminate the final product.

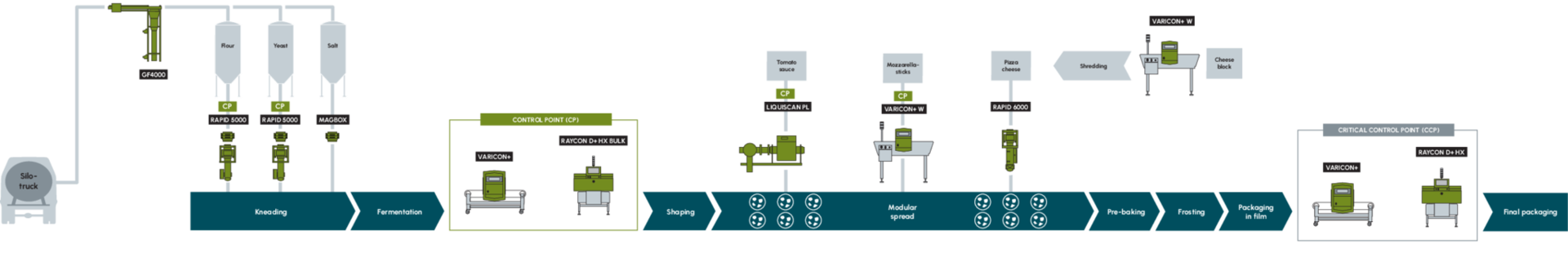

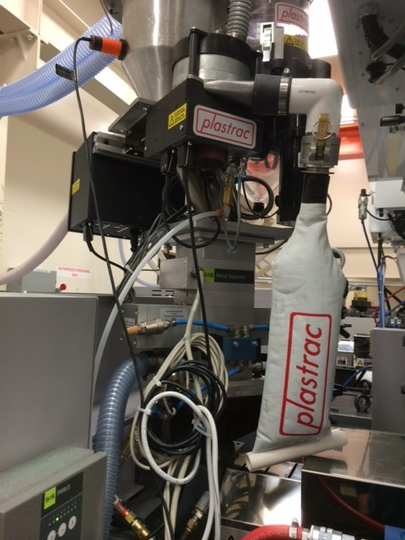

Across the Entire Production Line

From goods receipt to production to dispatch—our metal detection and X-ray inspection systems ensure the highest product purity and safe food production at every step.

Discover the Perfect Sesotec Solution with Ease

Are you interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

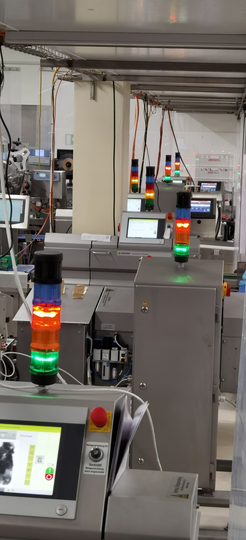

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of confectionery production.

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor in the confectionery industry, especially when it comes to certifications and audits.

LEGAL REQUIREMENTS

EU Regulation 178/2002 and national food laws require confectionery manufacturers to implement effective measures to prevent food contamination by foreign bodies.

CUSTOMER REQUIREMENTS

Consumers rightly demand the highest level of product safety from confectionery manufacturers. Even the slightest contamination can permanently damage trust in your brand.

PROTECTION AGAINST RECALLS AND DAMAGES

Confectionery manufacturers must minimize all risks of recalls, brand damage, and legal consequences.

Since implementing Sesotec's RAYCON devices, we've seen a proven reduction in consumer complaints about missing bars.

View Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)