FOREIGN BODY DETECTION FOR HYGIENE PRODUCTS

Clean Solution: Hygiene Products Without Foreign Bodies

Baby diapers, tampons, tissues, and similar hygiene products come into direct contact with the body. Foreign bodies, especially metals, can cause injuries—leading to recalls, compensation claims, and damage to brand reputation. We offer the right detection systems to minimize these risks.

Filter Out What Doesn't Belong

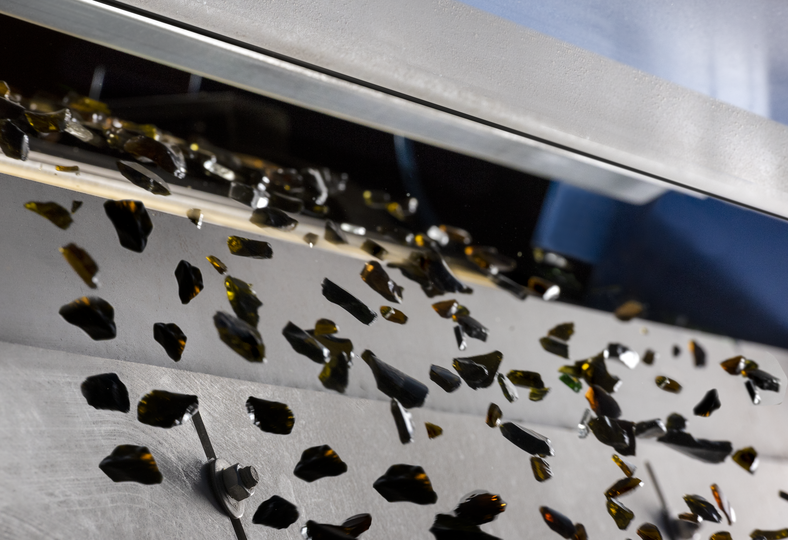

Iron

May originate from machine wear and impact product quality, for example, through the wear and breakage of processing machines and knives.

Stainless Steel

Common in production residues, harder to detect, yet crucial for purity.

Copper

Can enter production through various process steps. For example, from broken wires in cellulose bales.

Aluminum

Common potential contamination from packaging materials or machine parts.

Iron

May originate from machine wear and impact product quality, for example, through the wear and breakage of processing machines and knives.

Stainless Steel

Common in production residues, harder to detect, yet crucial for purity.

Copper

Can enter production through various process steps. For example, from broken wires in cellulose bales.

Aluminum

Common potential contamination from packaging materials or machine parts.

Are you facing issues with these or other foreign bodies?

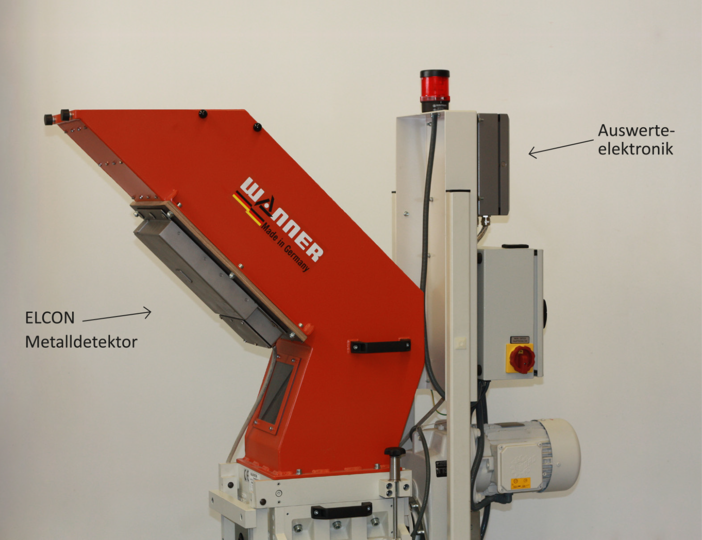

- Metal Detection and Separation

- Magnetic Systems

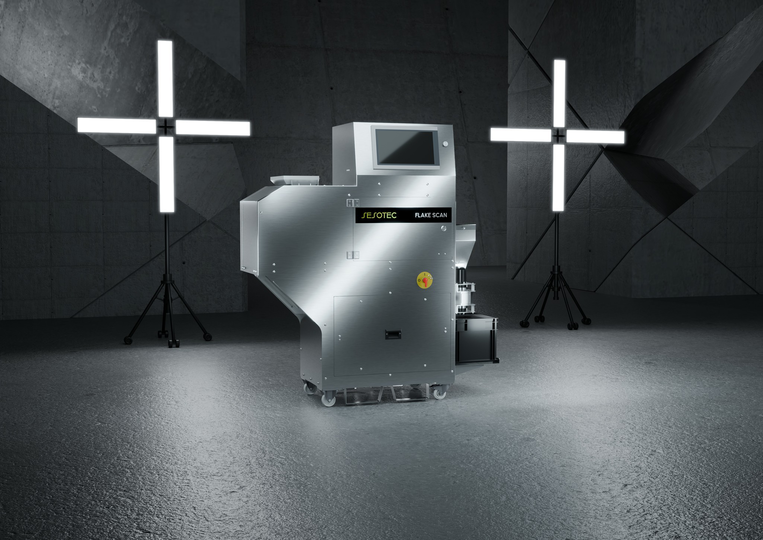

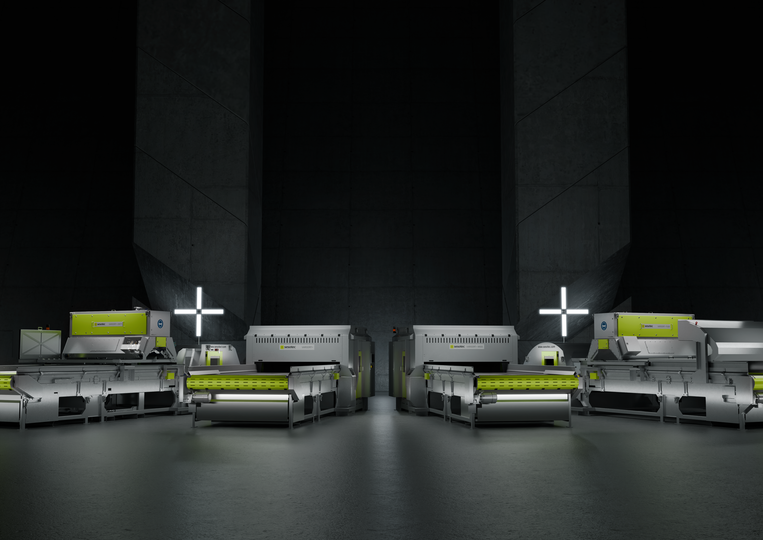

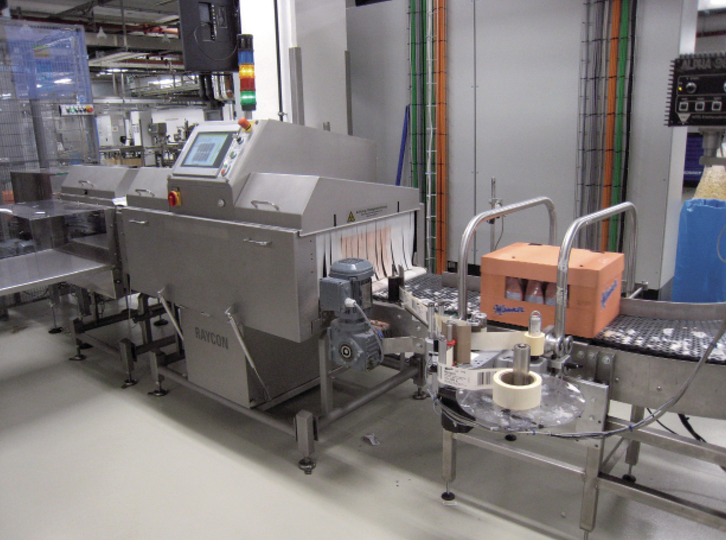

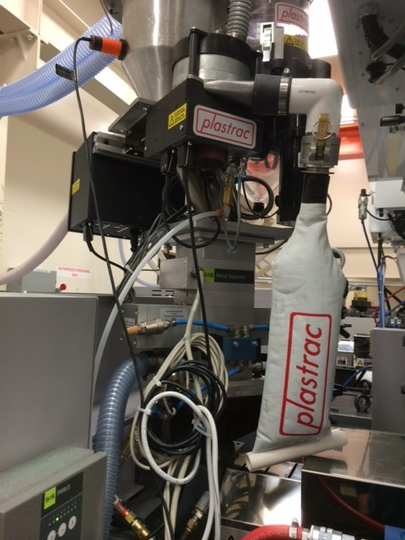

Metal Detection and Separation

With inductive technology, Sesotec metal detection systems identify all metallic foreign bodies in the chemical industry.

Magnetic Systems

Sesotec magnetic systems deliver exceptional magnetic performance and efficient design to eliminate even the finest ferrous metal contaminants.

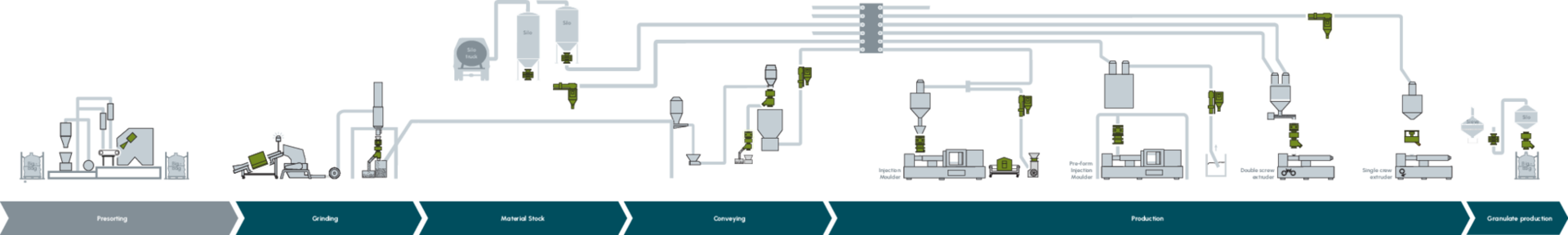

Where Are Sesotec Solutions Used in Hygiene Product Manufacturing?

Common applications include the removal of metallic contaminants right from the raw material inspection in fibers, pulps, or granulates.

Our solutions also prevent disruptions during processing and ensure the quality of diapers, wet wipes, and medical disposables at the end of production.

Diapers

Testing pulp and superabsorbents for metallic impurities.

Tampons & Liners

Ensuring the Purity of Cotton and Nonwoven Materials

Tissues

Inspection of paper webs for foreign bodies from production.

Wet Wipes & Toilet Paper

Detecting Metal Particles in Sensitive Fiber Materials

Face Masks and Respirators

Inspection of nonwovens and nose wires for contaminants.

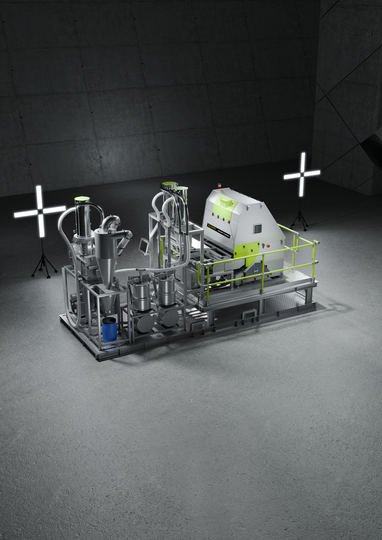

Across the Entire Production Line

Maximum security for your entire production: Our metal detection and magnet systems identify and remove foreign bodies throughout the production line. This ensures stable processes, compliant products, and high productivity—from material input to the finished product.

Discover the Perfect Sesotec Solution Here

Are You Interested?

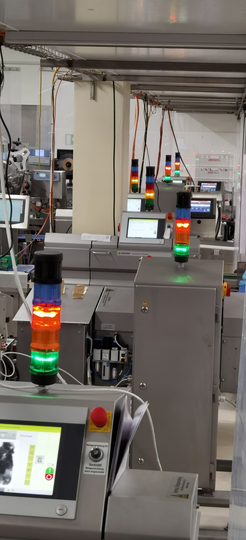

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of manufacturing hygiene products

Overall Equipment Effectiveness

Foreign bodies in production can lead to unexpected delays, increased maintenance, and reduced output.

Customer Demands and Quality

Manufacturers of hygiene products are under pressure to deliver products of the highest purity and quality. A foreign body in the final product jeopardizes customer satisfaction and can lead to complaints or loss of orders.

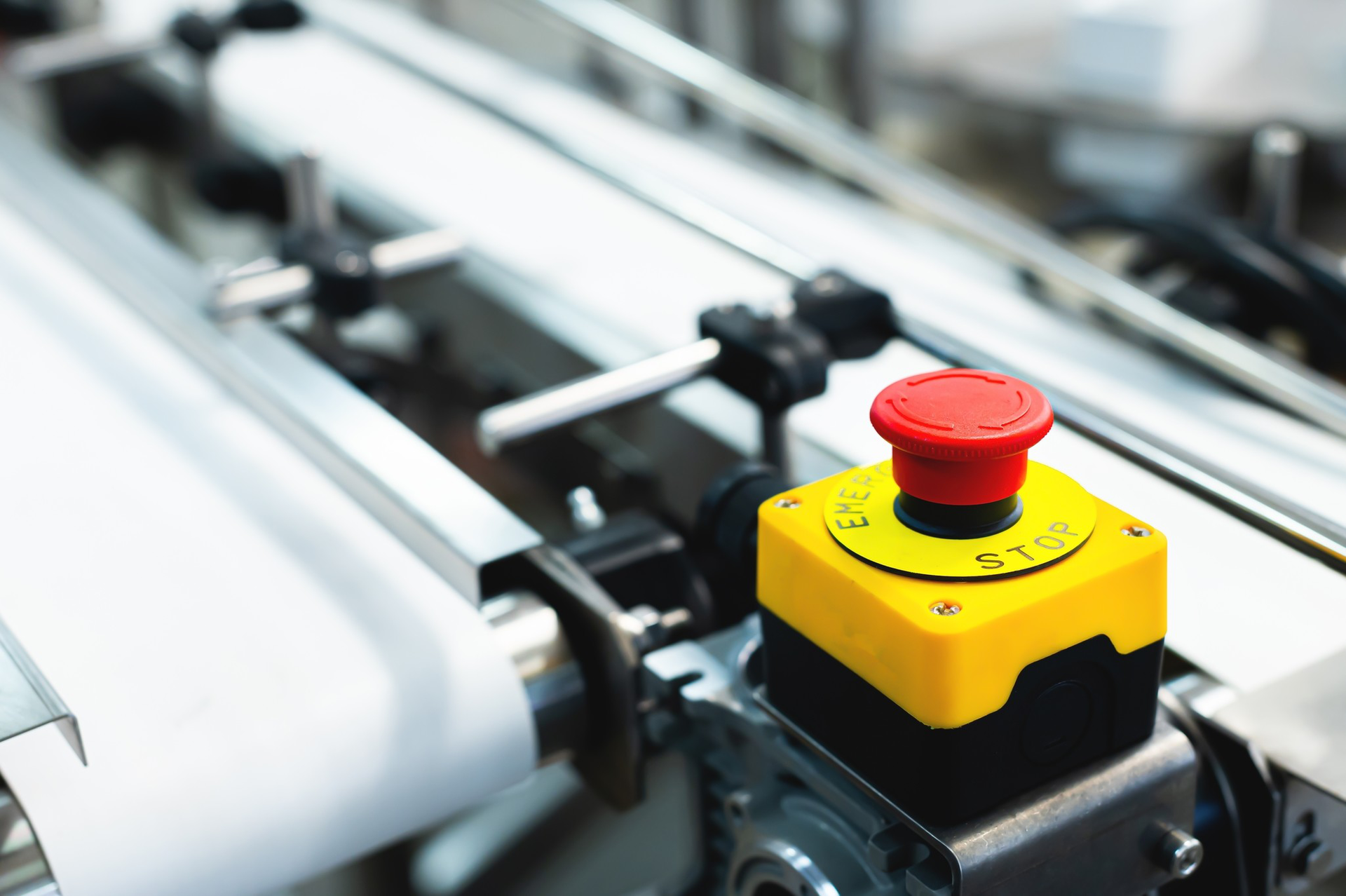

Prevent Production Downtime

Even small foreign bodies can halt production processes, leading to costly downtime and, in the worst case, the loss of entire batches.

Protect Against Machine Damage

Foreign bodies like metal parts or debris can damage sensitive production machinery. The result: high repair costs and production delays.

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)