METAL RECYCLING

Metal Matters

Metal scrap can be endlessly melted down and transformed into new products—without losing quality. Sesotec sorting systems extract metals from material streams and sort them by type. This ensures efficient and eco-friendly recycling.

Streamline Your Choices

Stainless Steel

Stainless steel is efficiently separated from other materials using electromagnetic sorting techniques, enabling its reuse in new products.

Iron

Iron is isolated from scrap streams using specialized electromagnetic separation techniques, allowing it to be reused in steel production.

Zinc

Zinc is separated from various metal mixtures through optical sorting. It can then be used, for example, in the production of alloys.

Aluminum

Aluminum is efficiently separated from mixed metals through optical or chemical differentiation.

Copper

Copper is extracted from scrap through optical sorting. It's a valuable metal that offers significant raw material gains through recycling.

Stainless Steel

Stainless steel is efficiently separated from other materials using electromagnetic sorting techniques, enabling its reuse in new products.

Iron

Iron is isolated from scrap streams using specialized electromagnetic separation techniques, allowing it to be reused in steel production.

Zinc

Zinc is separated from various metal mixtures through optical sorting. It can then be used, for example, in the production of alloys.

Aluminum

Aluminum is efficiently separated from mixed metals through optical or chemical differentiation.

Copper

Copper is extracted from scrap through optical sorting. It's a valuable metal that offers significant raw material gains through recycling.

Interested in recycling one of these materials?

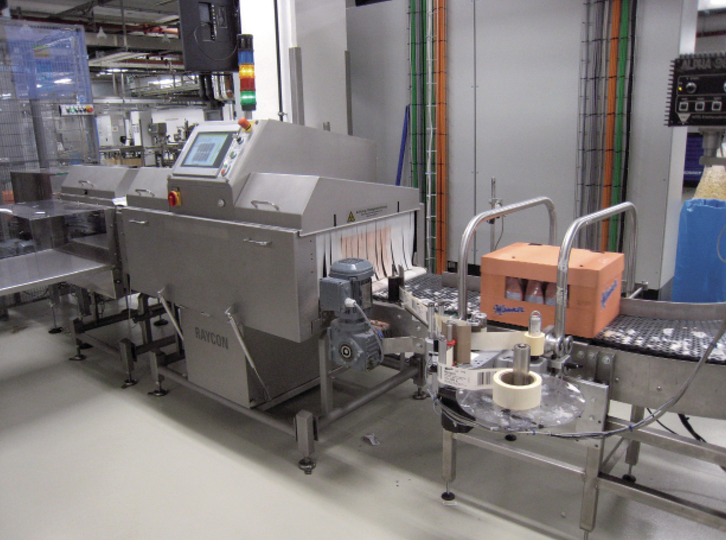

Recycling Sorting Systems

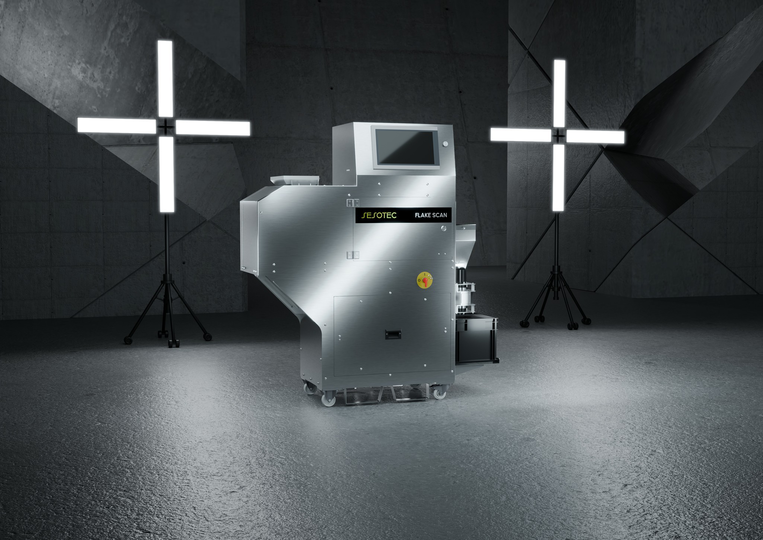

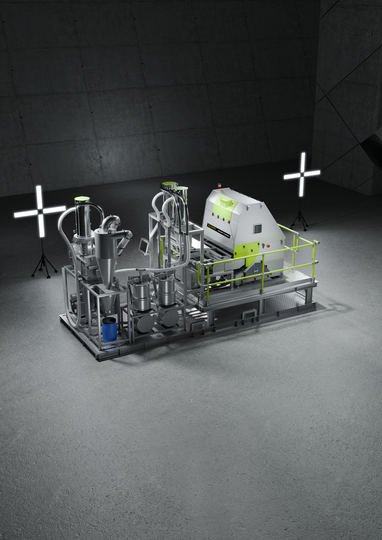

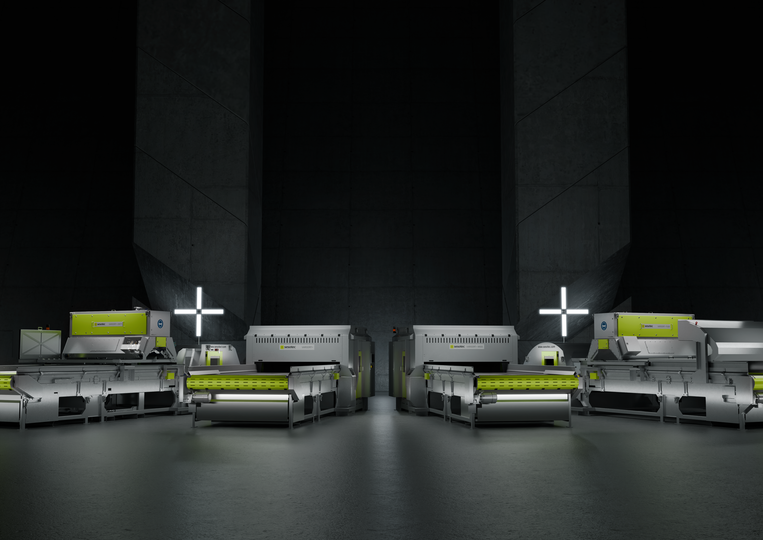

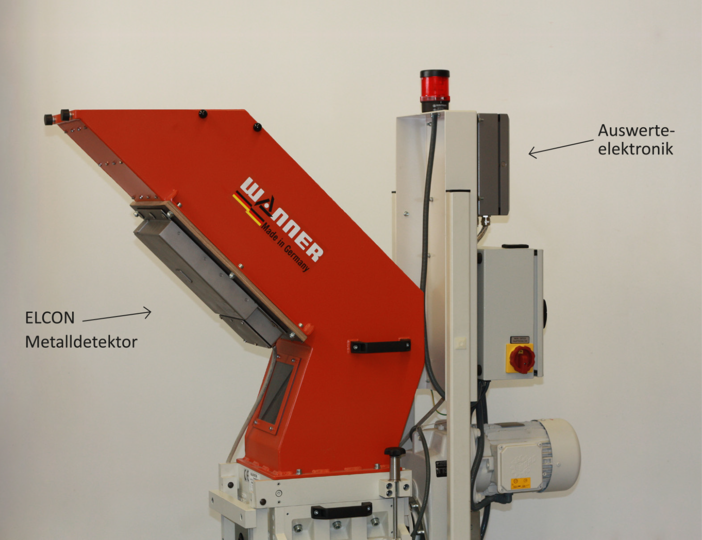

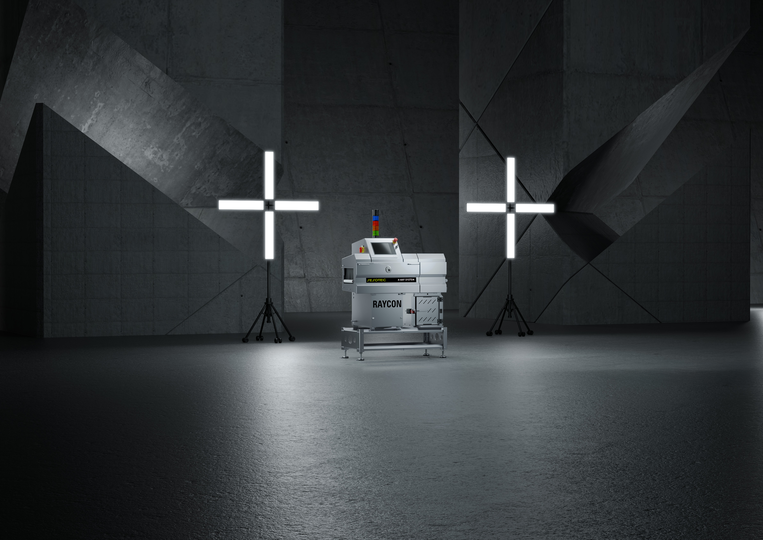

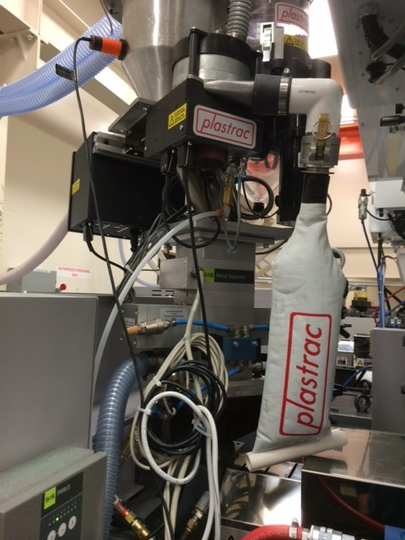

Separate impurities with air jets from a material stream analyzed by precise sensors on a chute or conveyor belt – enabling continuous, automated sorting of large volumes.

Where Do Metal Recyclers Use Sesotec Sorting Systems?

Businesses across industries rely on Sesotec sorting systems to efficiently separate materials and reclaim valuable resources.

Our systems ensure the precise sorting of all types of metals.

Sort Metals from Material Mixtures

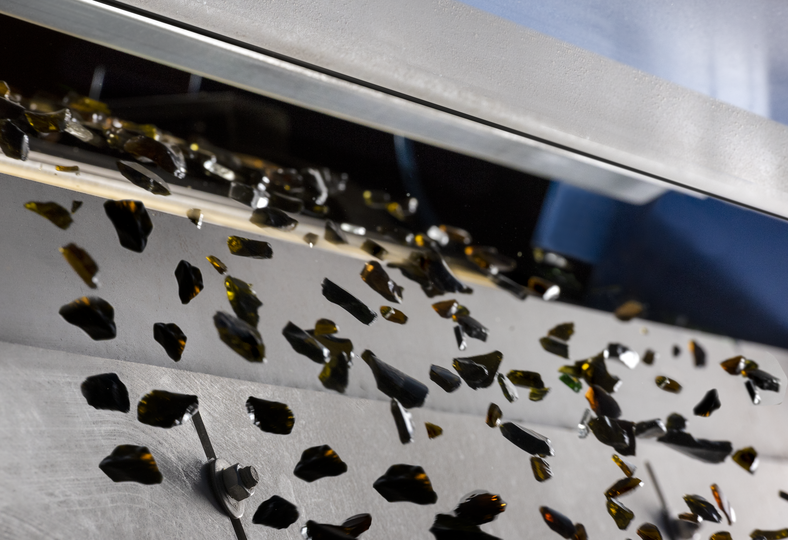

Sorting systems precisely separate metals from complex material mixtures like electronic waste.

Extraction of Ultra-Pure Metal Fractions

Advanced sorting techniques extract ultra-pure metal fractions like aluminum or stainless steel from mixed waste.

Sorting Visually Distinct Metal Types

Optical sorting systems use specialized sensors to identify and separate metals with different surfaces or colors, such as copper or zinc.

Sorting of Metal Alloys, Aluminum Castings, and Aluminum Wrought Alloys

Sorting systems identify and separate different metal alloys based on their chemical composition.

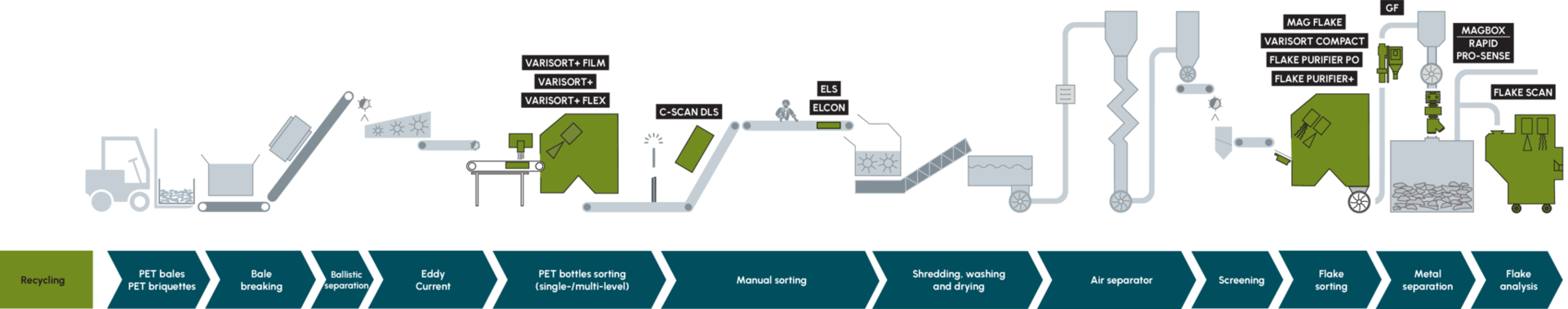

Across the Entire Production Line

From intake inspection to sorting and analysis – our systems reliably separate, sort, and analyze. This ensures superior material quality and cost-effective recycling throughout the entire process.

Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

Smart Enhancements for Unmatched Performance

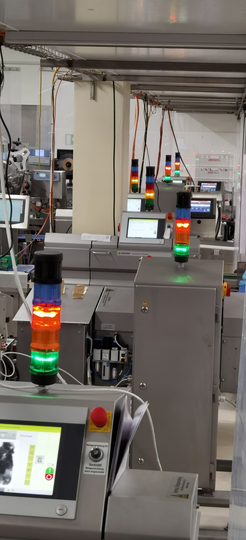

Unlock actionable insights from process data to boost the efficiency of your sorting and recycling operations and minimize downtime. VISUDESK, the visualization software for sorting machines and systems, brings transparency to your sorting processes with process data, enabling direct control for enhanced efficiency and profitability.

Enhance Clarity in

Your Sorting Processes

Unleash Total Control

Over Your Sorting Systems

Boost Profitability with

Data-Driven Optimization

We understand the challenges of metal recycling.

Recover Valuable Secondary Raw Materials

Sorting systems empower efficient separation and recovery of diverse raw materials, conserving natural resources and reducing the demand for new ones.

Secure Removal of Contaminants

Ensuring the safe removal of contaminants in recycling is crucial for maintaining material quality, preventing process disruptions, and protecting machinery.

Customer Needs and Quality

Sesotec sorting systems ensure material purity that meets your customers' quality standards. Strengthen your market position and promote sustainable economic cycles.

Legal Requirements

Meet regulatory requirements effortlessly with Sesotec sorting systems, including waste separation and recycling rates.

Sesotec systems are the top choice for sorting and cleaning diverse material groups in our facility.

Explore Case Studies

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)