Where Purity Takes Shape

Metallic impurities cause numerous issues in plastic processing. Sesotec's foreign body detectors reliably identify metals, preventing machine damage and production downtime. For companies processing plastics, this means not only higher product quality but also improved overall equipment effectiveness.

Remove What Doesn't Belong

Ferrous Metals

Foreign bodies made of iron can enter production through abrasion from machines or transport lines.

Aluminum

Lightweight aluminum parts often integrate seamlessly into machine components for plastic processing.

Copper

Copper particles from electrical wiring or machine wear can act as conductive foreign bodies, leading to production defects or negatively impacting the properties of the plastic.

Stainless Steel

Stainless steel particles can disrupt processing, affect material consistency, and cause visible defects in the final product.

Brass

Brass, with its abrasive nature, can damage surfaces and compromise the visual quality of transparent or high-precision plastic components.

Ferrous Metals

Foreign bodies made of iron can enter production through abrasion from machines or transport lines.

Aluminum

Lightweight aluminum parts often integrate seamlessly into machine components for plastic processing.

Copper

Copper particles from electrical wiring or machine wear can act as conductive foreign bodies, leading to production defects or negatively impacting the properties of the plastic.

Stainless Steel

Stainless steel particles can disrupt processing, affect material consistency, and cause visible defects in the final product.

Brass

Brass, with its abrasive nature, can damage surfaces and compromise the visual quality of transparent or high-precision plastic components.

Are you struggling with these or other foreign bodies?

- Metal Detection and Separation

- Magnetic Systems

- Material Management

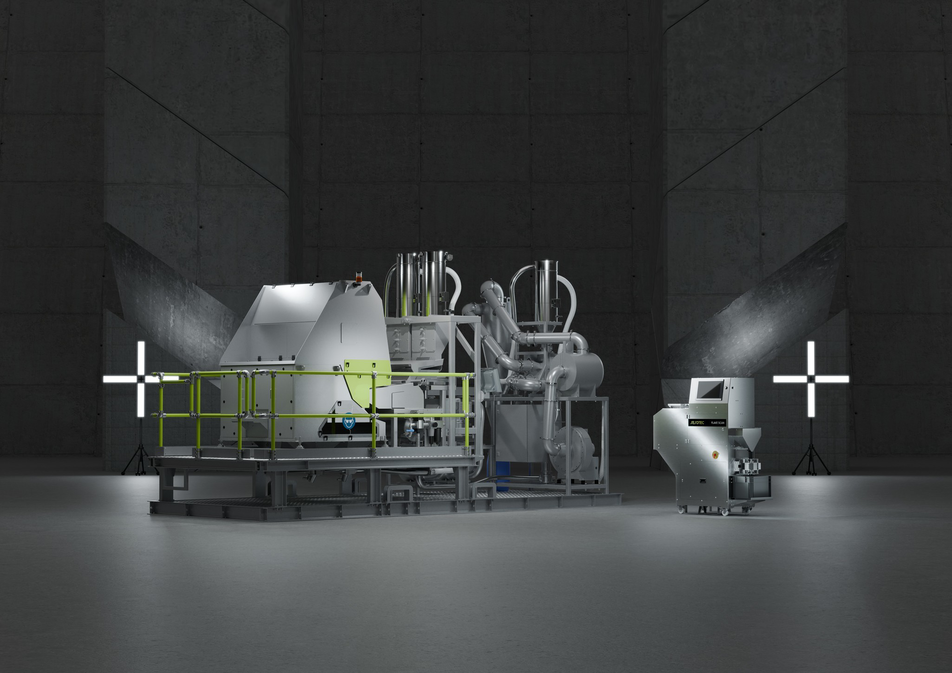

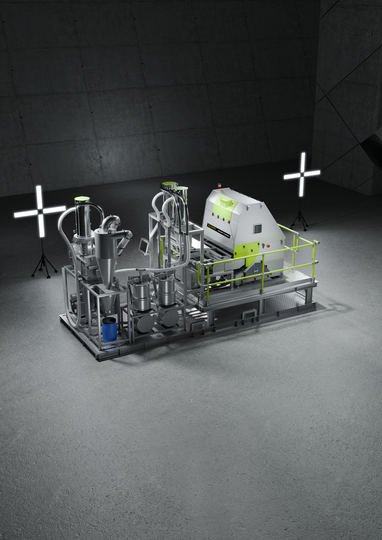

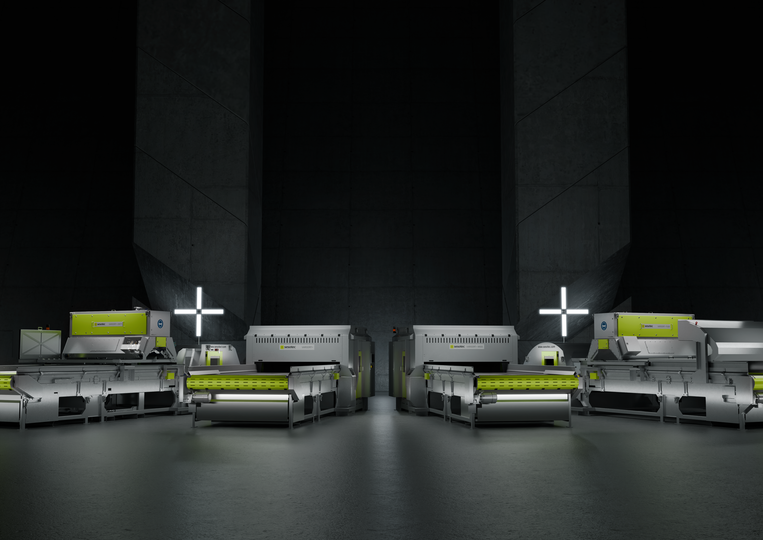

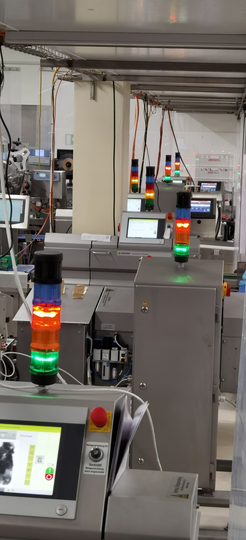

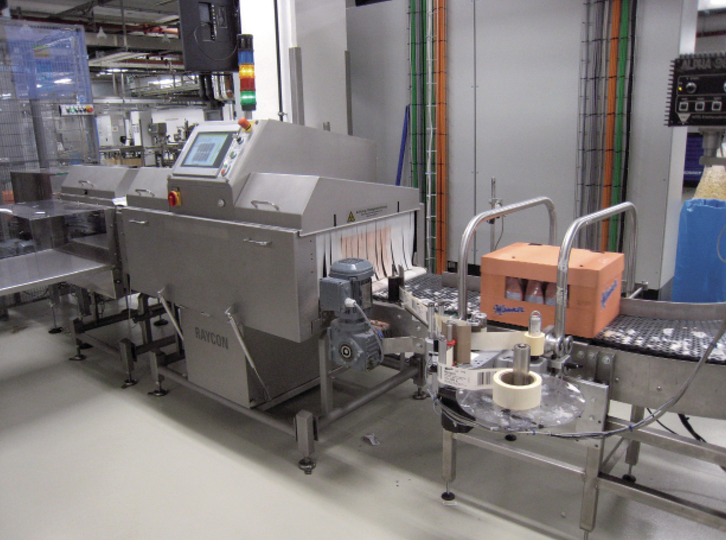

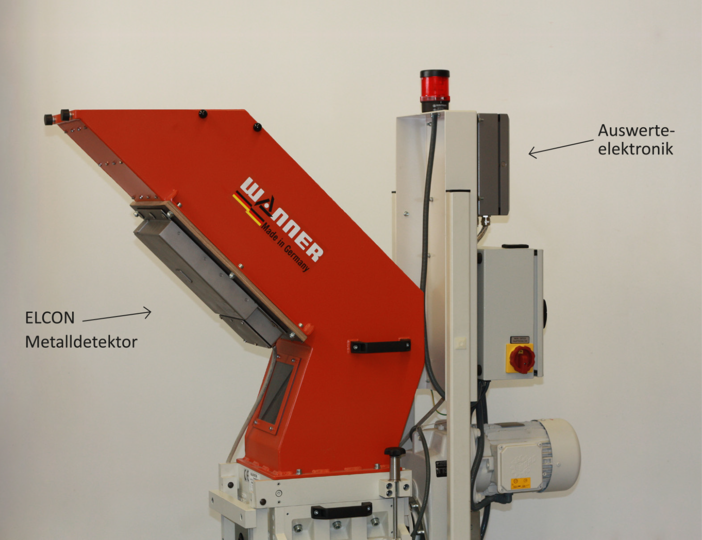

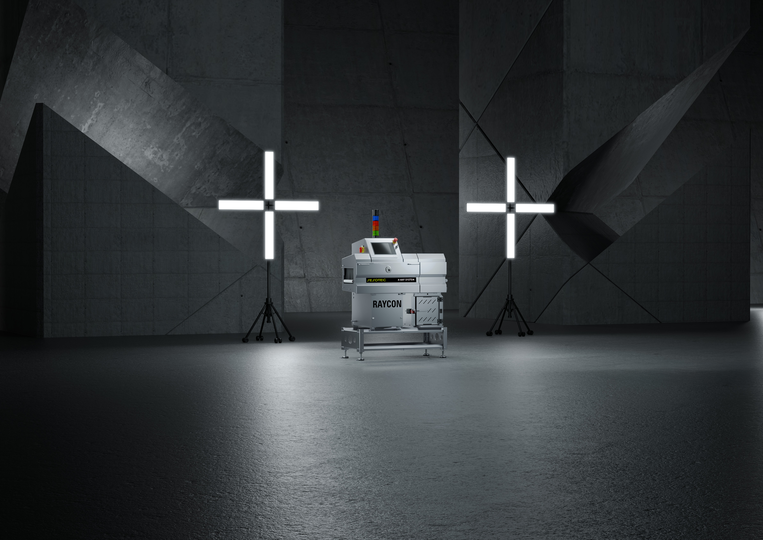

Metal Detection and Separation

Using inductive technology, Sesotec metal detection systems identify all metallic foreign bodies in plastic production.

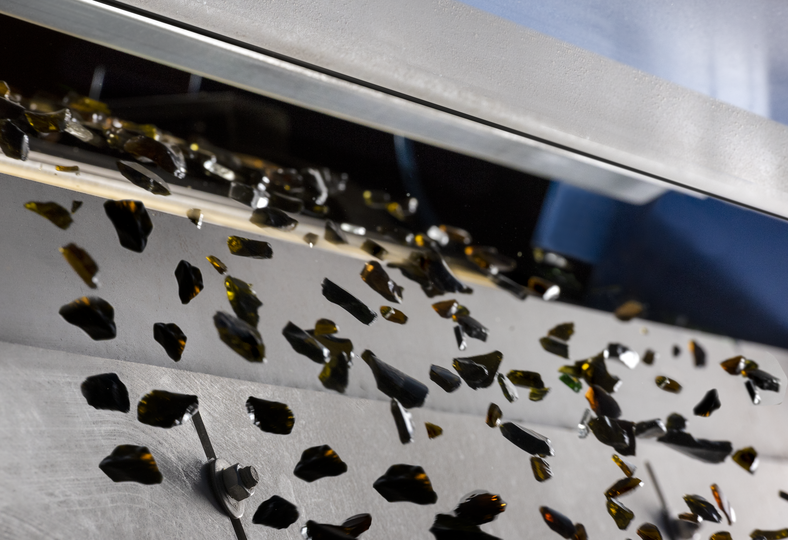

Magnetic Systems

Sesotec magnetic systems deliver exceptional magnetic performance and efficient design to eliminate even the finest ferrous metal contaminants.

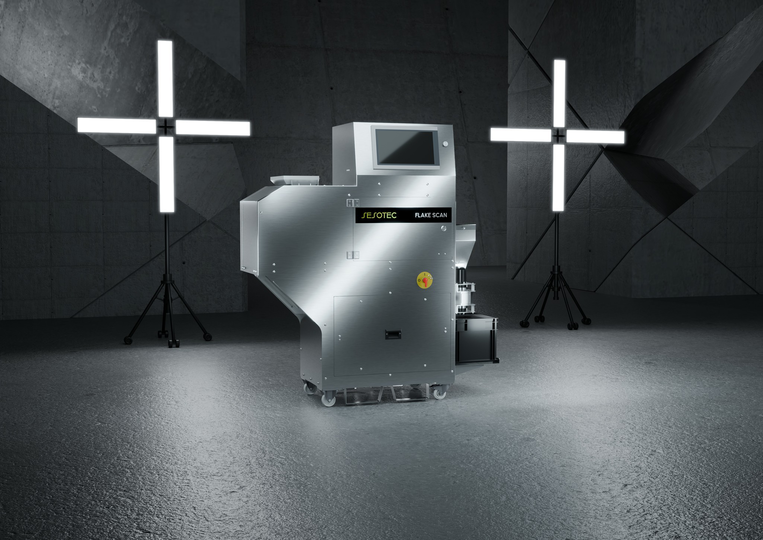

Material Management

FLAKE SCAN and PRE-SORT systems ensure top-tier material quality for plastic processors.

Where are Sesotec solutions used in plastics processing?

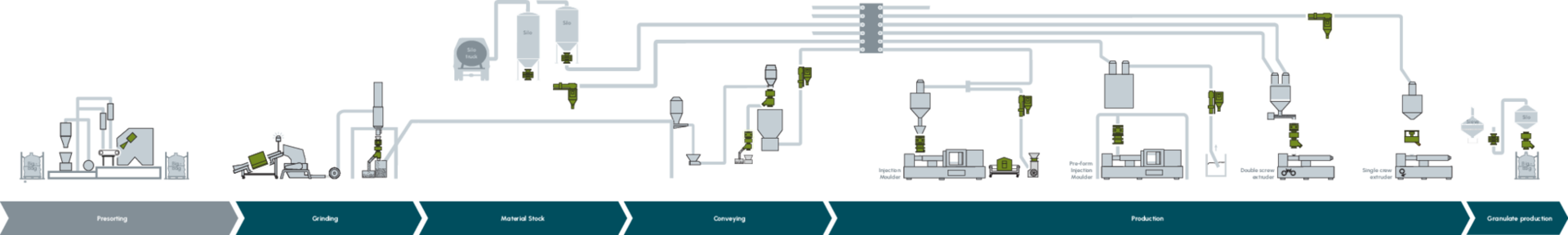

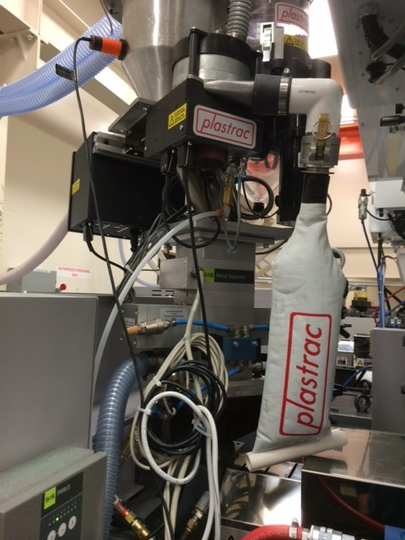

Our Sesotec solutions are integral to every stage of your production chain—from material feed to the finished product.

They safeguard your machinery from damage caused by metal contaminants, ensure material purity, and maintain consistently high product quality. Common applications include granulate processing, extrusion, injection molding, and blow molding processes.

Recycled Material

Recycled plastics can contain foreign bodies such as metals, glass, or other impurities that enter the material during the recycling process.

Granules

Plastic granules can become contaminated by metal abrasion, machine parts, or other particles during production, storage, or transport.

Additive

Chemical additives that enhance the properties of plastics may contain unwanted particles, either from the manufacturing process or due to handling errors.

Fillers

Fillers like talc or calcium carbonate may contain foreign bodies such as mineral impurities.

Color Masterbatches

Concentrated color blends can be compromised by foreign particles, disrupting the uniformity and color quality of the final product.

Across the Entire Production Line

Maximum security for your entire production: Our metal detection and magnet systems identify and remove foreign bodies throughout the production line. This ensures stable processes, compliant products, and high productivity—from material intake to the finished product.

Discover the perfect Sesotec solution with ease:

Are You Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of plastic processing.

Overall Equipment Effectiveness

Foreign bodies in production can lead to unexpected delays, increased maintenance, and reduced output.

Customer Demands and Quality

The plastics processing industry is under pressure to deliver products of the highest purity and quality. Foreign bodies in the final product jeopardize customer satisfaction and can lead to complaints or loss of orders.

Avoid Production Downtime

Even small foreign bodies can halt production processes, leading to costly downtime and, in the worst case, the loss of entire batches.

Protect Against Machine Damage

Foreign bodies like metal parts or debris can damage sensitive production machinery. The result: high repair costs and production delays.

The initial RAPID PRO-SENSE units are performing exceptionally well in production. We are extremely pleased with the results.

VIEW CASE STUDIES

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)