GLASS RECYCLING

Crystal Clear Sustainability

Glass can be recycled endlessly without losing quality. However, glassworks have stringent requirements for shard quality. Sesotec systems empower recycling companies to meet these high standards: they inspect shards, eliminate contaminants like ceramics, stones, or porcelain, and sort materials by glass color and type. The result: recycling rates of up to 100 percent.

Streamline Your Choices

Clear Glass

Clear glass is meticulously separated from other types to maintain its purity.

Green and Brown Glass

Green and brown glass are separated using specialized sorting technologies to prevent contamination.

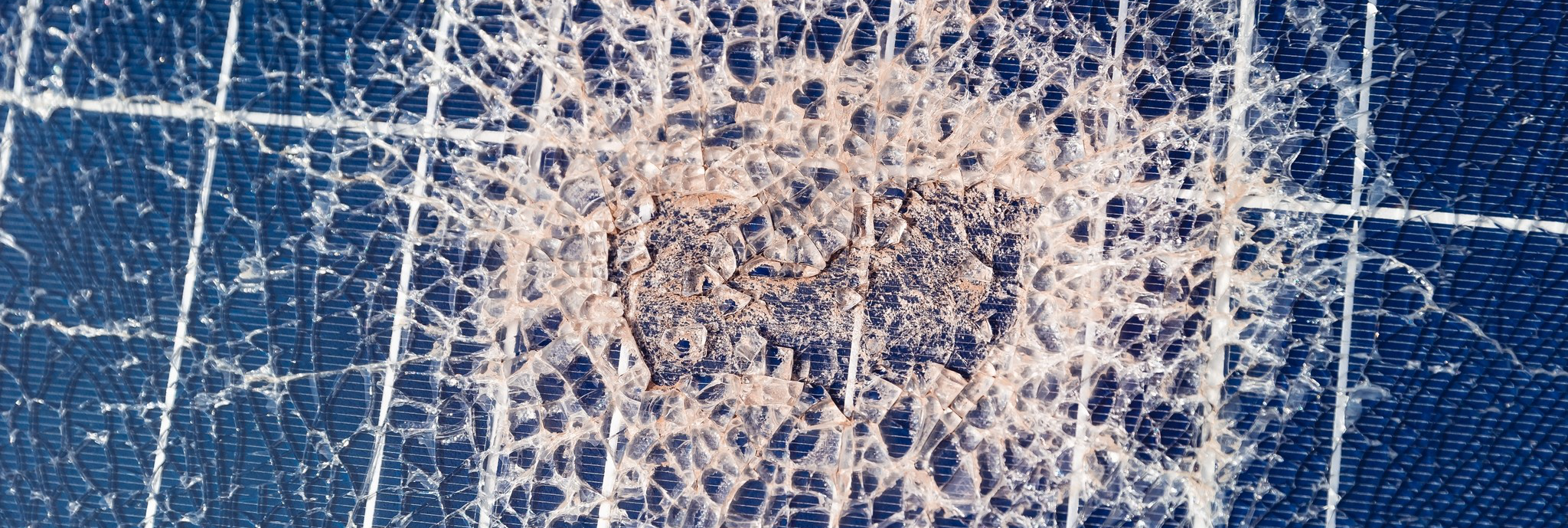

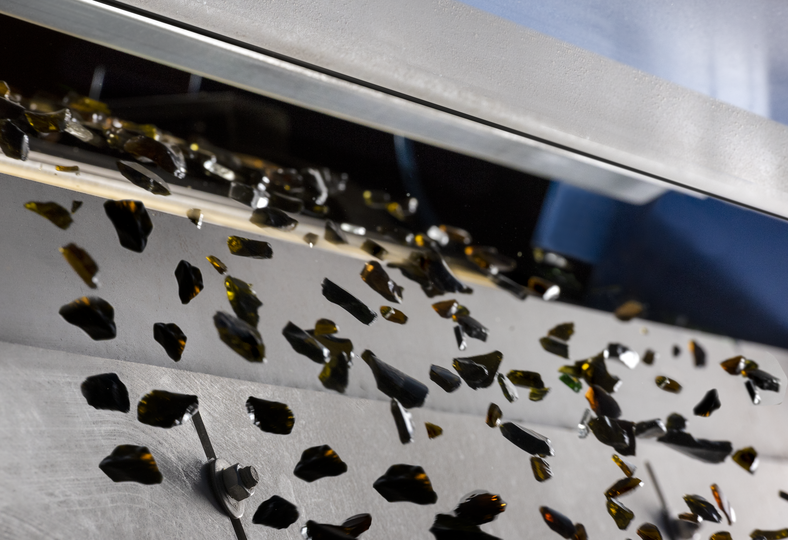

Foreign body in recycled glass

Sorting systems identify and remove foreign bodies like metal, plastic, or wood from waste glass.

Lead Glass

Lead glass is meticulously sorted using specialized processes to ensure flawless quality.

Heat-Resistant Glass

Advanced sorting systems separate heat-resistant glass, commonly found in kitchen environments.

Clear Glass

Clear glass is meticulously separated from other types to maintain its purity.

Green and Brown Glass

Green and brown glass are separated using specialized sorting technologies to prevent contamination.

Foreign body in recycled glass

Sorting systems identify and remove foreign bodies like metal, plastic, or wood from waste glass.

Lead Glass

Lead glass is meticulously sorted using specialized processes to ensure flawless quality.

Heat-Resistant Glass

Advanced sorting systems separate heat-resistant glass, commonly found in kitchen environments.

Interested in recycling one of these materials?

Excellence in Separation

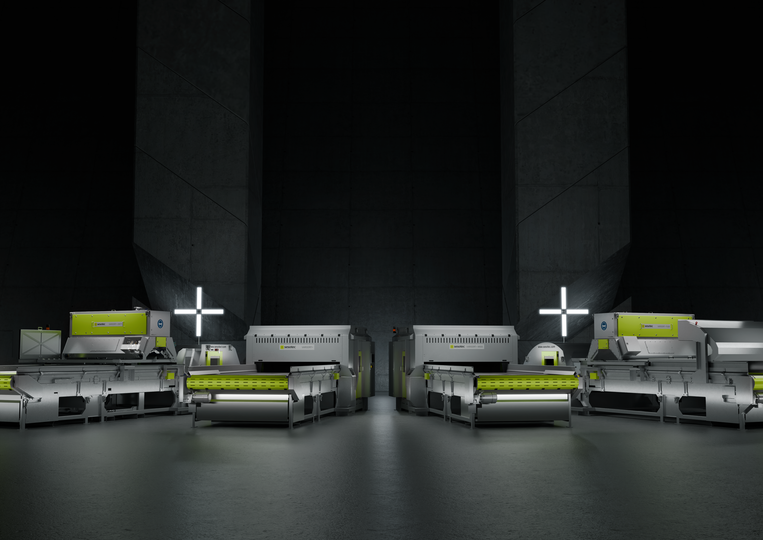

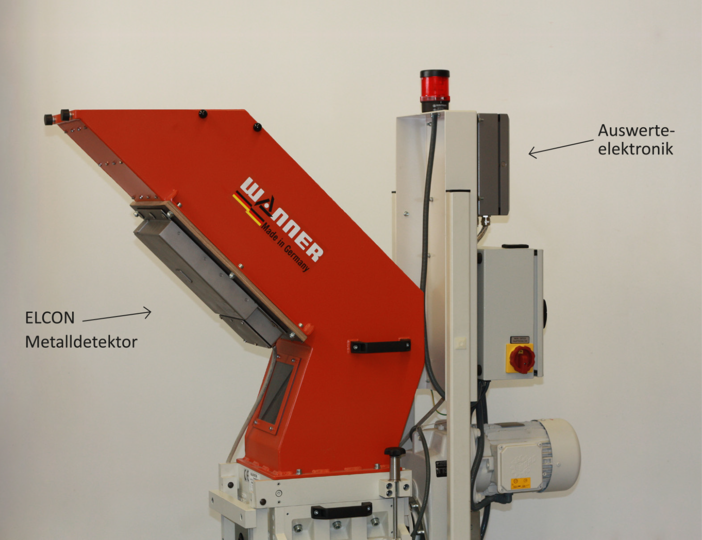

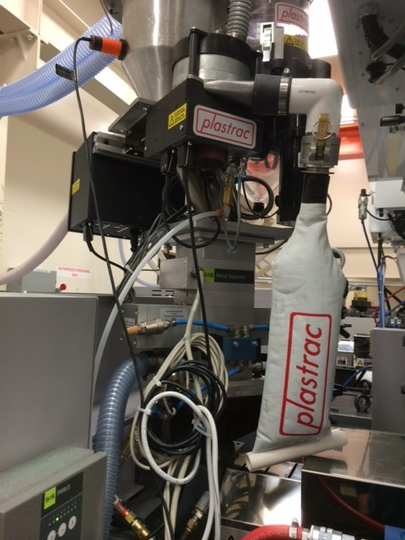

- Recycling Sorting Systems with Chute

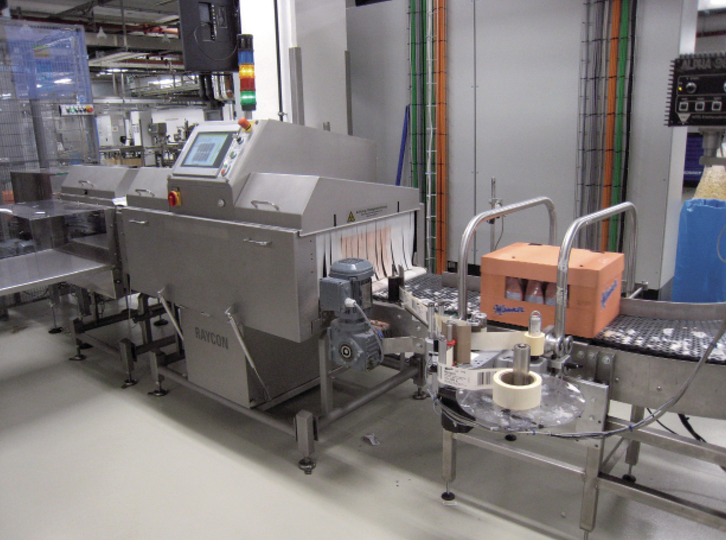

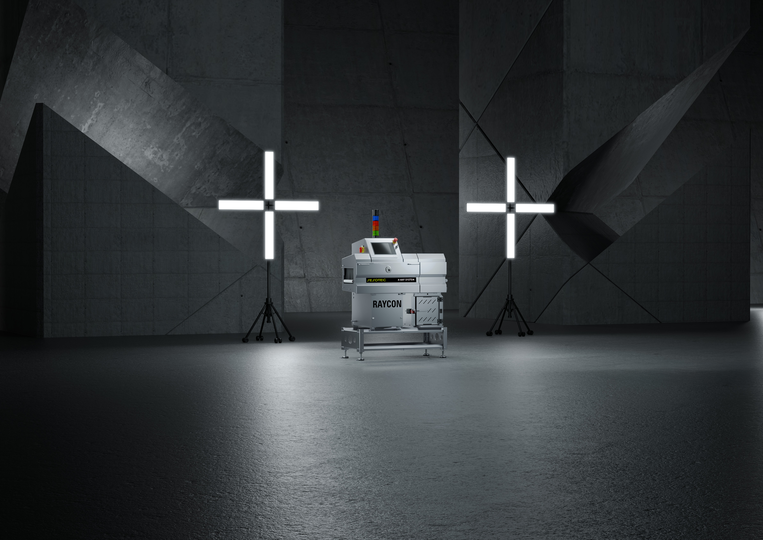

- Recycling Sorting Systems with Conveyor Belt

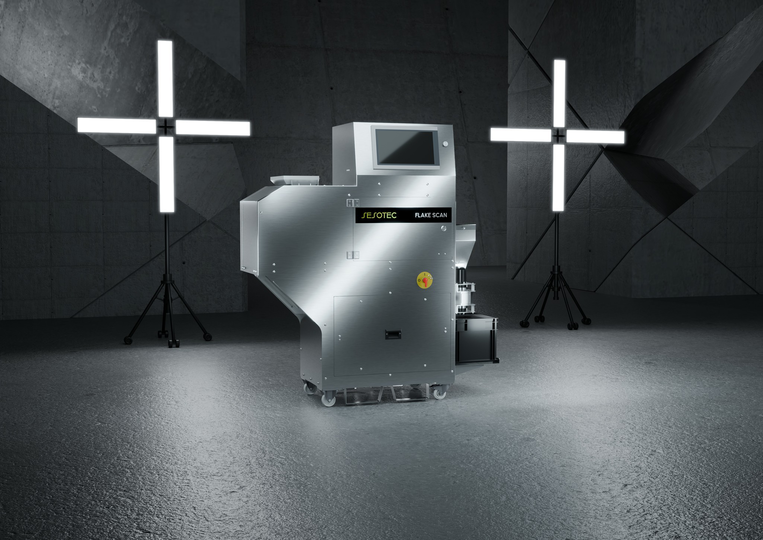

Recycling Sorting Systems with Chute

Remove impurities from a material stream with air jets, precisely analyzed by advanced sensors on a chute.

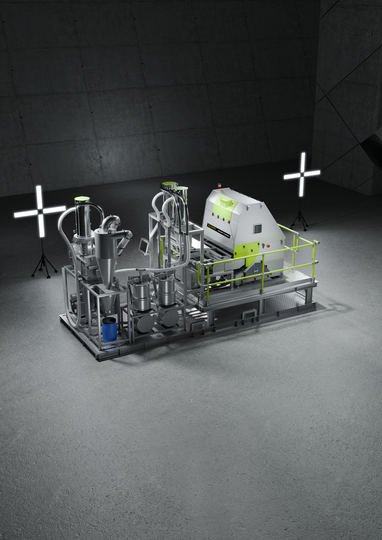

Recycling Sorting Systems with Conveyor Belt

Effortless material separation on a conveyor system; designed for continuous and automated sorting of large volumes.

Where Do Glass Recyclers Use Sesotec Sorting Systems?

Businesses across industries rely on Sesotec sorting systems to efficiently separate materials and reclaim valuable resources.

Our systems ensure efficient sorting and guarantee an almost 100% recycling rate.

Vacuum Glass

Sesotec sorting systems separate hollow glass like bottles and jars by color and purity, enabling efficient recycling.

Flat Glass

Sesotec sorting systems identify and separate glass from windows or displays.

Specialty Glass

For specialty glass, such as leaded or heat-resistant types, Sesotec sorting systems employ advanced technologies for precise separation.

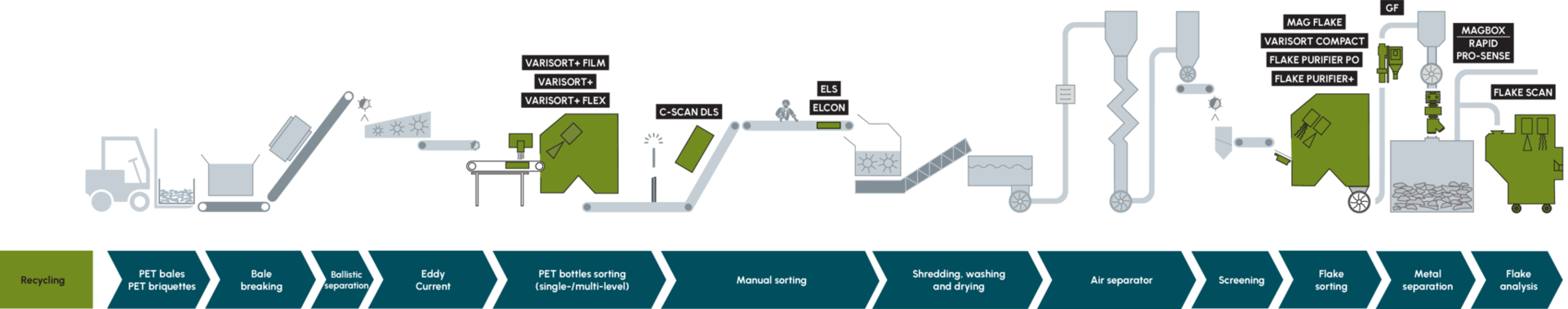

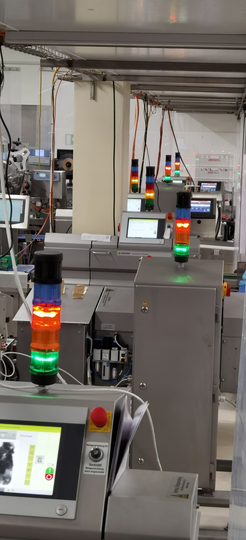

Across the Entire Production Line

From intake inspection to sorting and analysis, our systems reliably separate, sort, and analyze. They ensure high material quality and efficient recycling throughout the entire process.

Effortlessly discover the perfect Sesotec solution here

Interested?

ADD-ONS & SERVICES

Smart Enhancements for Unmatched Performance

Unlock actionable insights from process data to boost the efficiency of your sorting and recycling operations and minimize downtime. VISUDESK, the visualization software for sorting machines and systems, brings transparency to your sorting processes with process data, enabling direct control for enhanced efficiency and profitability.

Enhance Clarity in

Your Sorting Processes

Unleash Total Control

Over Your Sorting Systems

Boost Profitability with

Data-Driven Optimization

We understand the challenges of glass recycling.

Recover Valuable Secondary Raw Materials

Sorting systems enable the efficient separation and recovery of diverse raw materials. This conserves natural resources and reduces the demand for new materials.

Secure Removal of Contaminants

Secure removal of contaminants in recycling is crucial to maintain material quality, prevent process disruptions, and protect machinery.

Customer Needs and Quality

Sesotec sorting systems ensure material purity that meets your customers' quality demands. Strengthen your market position and promote sustainable economic cycles.

Legal Requirements

Comply with regulations like waste separation and recycling rates using Sesotec sorting systems.

With Sesotec's new technology, more valuable dark shards stay in the material cycle.

Read the Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)