READY-TO-EAT DELIGHTS

Instant Safety for Ready-to-Eat Meals

Consumers love convenience products and rely on consistently high quality. Sesotec inspection systems set new standards in foreign body detection, ensuring that only products meeting the highest demands reach the shelves. Protect your products with cutting-edge technology – for quality you can taste and trust.

The Most Common Foreign Bodies in Canned and Ready Meals

Metal Wear

Even tiny metal particles from abrasion can be hazardous, causing injuries if ingested or damaging sensitive equipment.

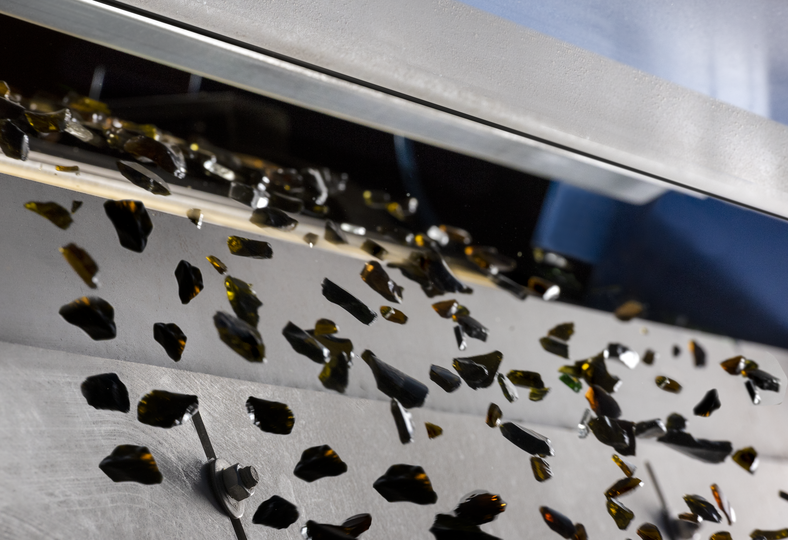

Shattered Glass

Glass shards can enter production through broken glass components like lights or containers. They are among the most hazardous foreign bodies, making thorough detection absolutely essential.

Stones

Stones can inadvertently enter the production process during raw material processing, such as with grains, legumes, or spices.

Plastics

Plastic parts often come from packaging, crates, or faulty machine components, posing injury risks and threatening product quality.

Metal Wear

Even tiny metal particles from abrasion can be hazardous, causing injuries if ingested or damaging sensitive equipment.

Shattered Glass

Glass shards can enter production through broken glass components like lights or containers. They are among the most hazardous foreign bodies, making thorough detection absolutely essential.

Stones

Stones can inadvertently enter the production process during raw material processing, such as with grains, legumes, or spices.

Plastics

Plastic parts often come from packaging, crates, or faulty machine components, posing injury risks and threatening product quality.

Foreign bodies in your canned goods, frozen foods, and ready meals?

Technology that Builds Trust

- X-ray Inspection

- Metal Detection

- Magnetic Systems

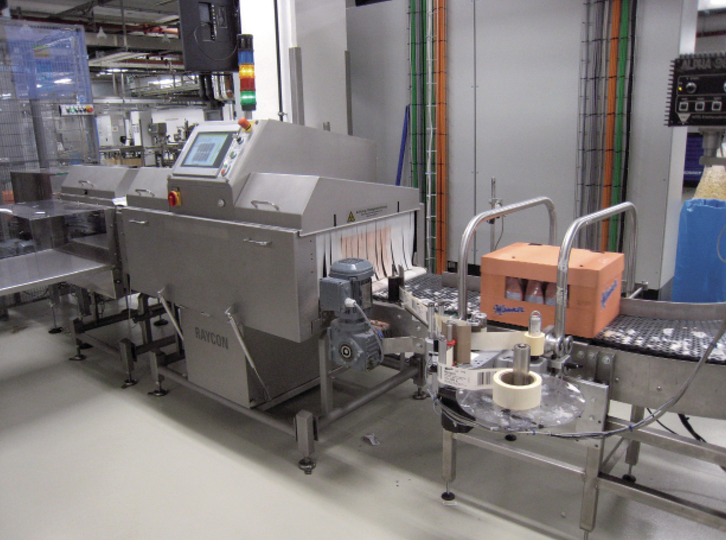

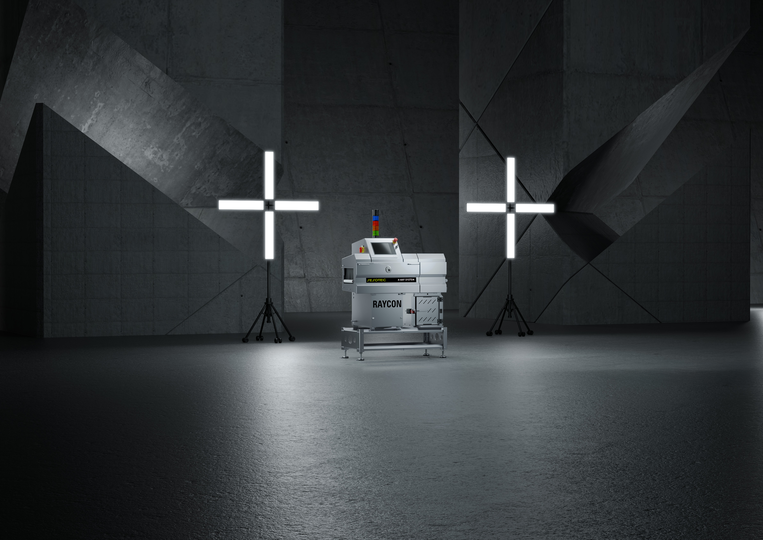

X-ray Inspection

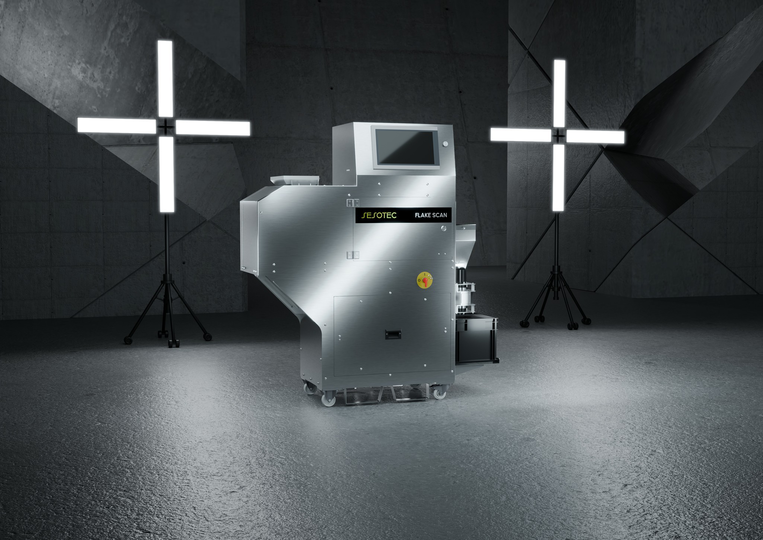

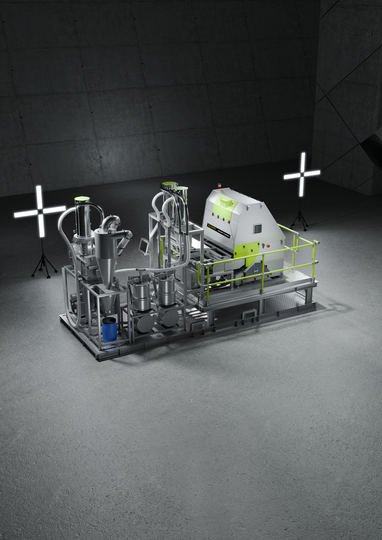

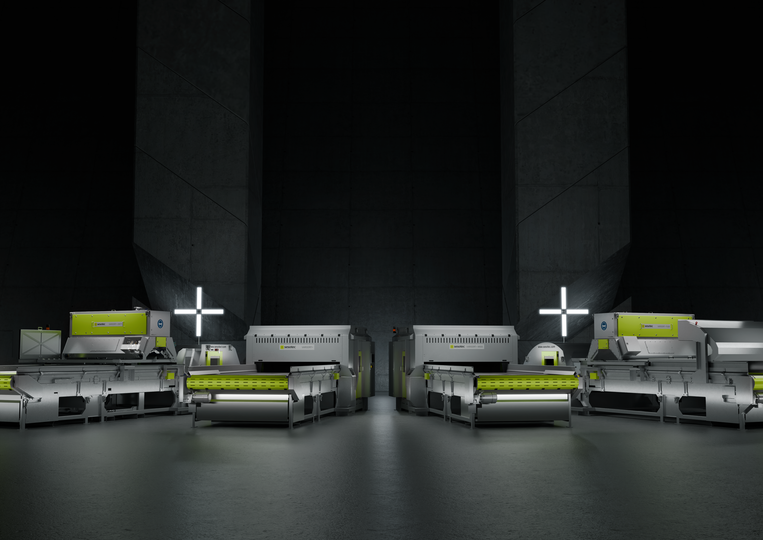

Our X-ray inspection systems ensure the ultra-precise detection of foreign bodies such as stones, metal shavings, glass shards, plastic, or wood during the production of convenience products.

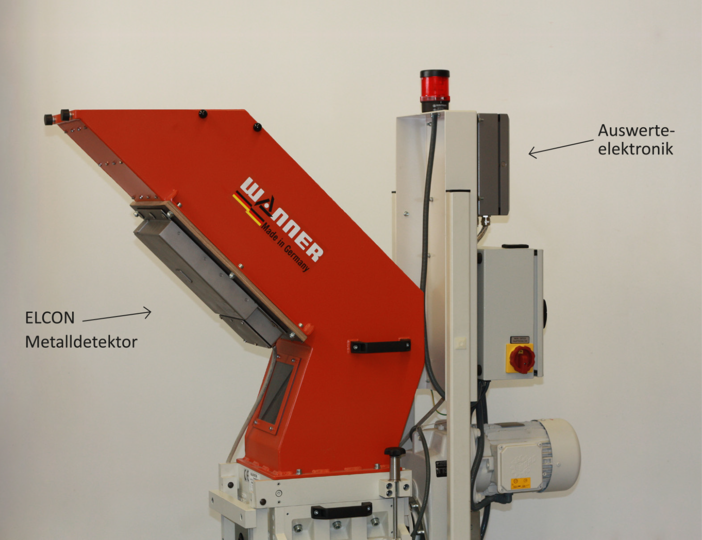

Metal Detection

Sesotec metal detection systems reliably identify metallic contaminants in canned goods, frozen foods, and ready meals.

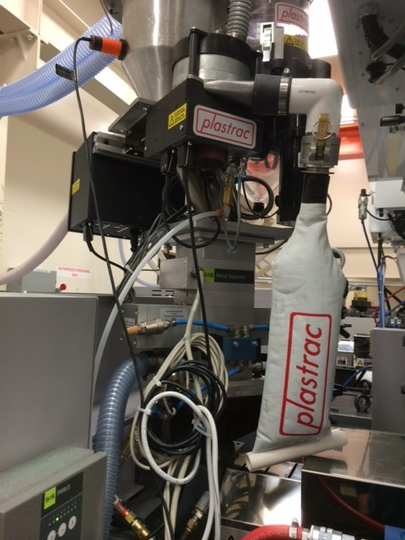

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from convenience products before further processing.

Powerful Solutions for Every Aspect of Canned Goods, Frozen Foods, and Ready Meals

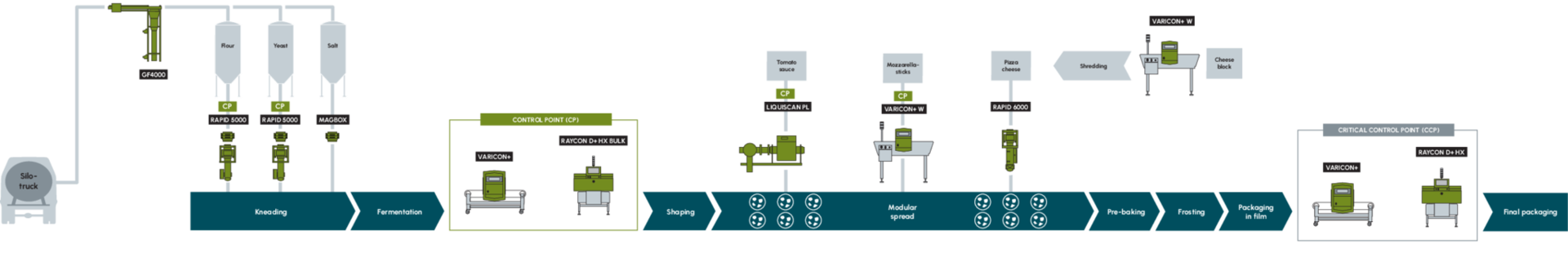

Sesotec metal detectors and X-ray scanners are perfect for every stage of your production process—from goods receipt to final inspection of packaged products.

Our modular design allows detection systems to be tailored to your specific operational needs.

Instant Meals

Sesotec detectors ensure instant meals are swiftly and reliably inspected, allowing consumers to enjoy everything from soups to pasta dishes with complete confidence.

Microwave Meals

With microwave meals, speed isn't the only priority—safety matters too. Our foreign body detection ensures products remain free from contaminants, meeting the highest quality standards for quick, risk-free enjoyment.

Frozen Fish Fillets

Effective foreign body detection safeguards frozen products like fish fillets from unwanted particles, ensuring only the finest quality reaches the plate – fresh and pure.

Frozen Pizzas

For frozen pizzas, foreign body detection ensures maximum protection with every bite. Thorough inspection guarantees worry-free enjoyment and uncompromising quality – pizza as it should be.

Frozen Vegetables

Sesotec detection devices safeguard against contamination, ensuring that frozen peas, broccoli, carrots, and more reach consumers not only fresh but also free from foreign bodies.

Across the Entire Production Line

From goods receipt to production to dispatch, our metal detection and X-ray inspection systems ensure maximum product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

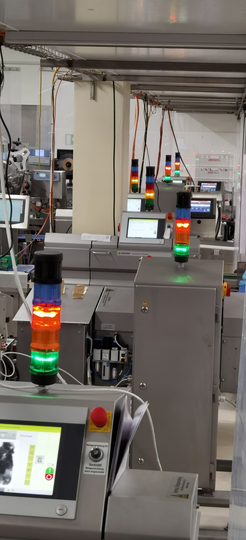

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of producing convenience food

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor for certifications and audits in canned goods, frozen foods, and ready meals. Reliable foreign body detection plays a key role in maintaining hygiene standards and meeting quality requirements according to international standards like IFS or BRC.

LEGAL REQUIREMENTS

Laws like EU Regulation 178/2002 and national food laws require manufacturers to implement effective measures to prevent contamination of canned goods, frozen foods, and ready meals with foreign bodies. Failure to comply with these regulations can lead to consequences such as recalls, fines, or the revocation of operating licenses.

CUSTOMER REQUIREMENTS

Customers rightly demand the highest level of product safety and quality from convenience products. Consumers and trade partners increasingly require guaranteed standards. Even the slightest contamination can permanently damage trust in your brand.

PROTECTION AGAINST RECALLS AND DAMAGES

Manufacturers of convenience products must minimize all risks of recalls, reputational damage, and legal consequences.

Sesotec's X-ray technology provided the support we needed to tackle the stone issue and meet our quality standards

Read the Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)