PROFITABLE CIRCULAR ECONOMY

Welcome to the Future of Circular Economy.

Resource scarcity, pollution, and climate change demand a radical shift in how we use raw materials. At the heart of this transformation is the circular economy, where what was once considered waste is now seen as a valuable resource. This vision only succeeds when recycling processes yield the purest materials possible.

Our cutting-edge technologies and services empower recycling companies to profitably produce high-quality secondary raw materials—ensuring sustainable and economically viable material cycles.

Why Separate Contaminants?

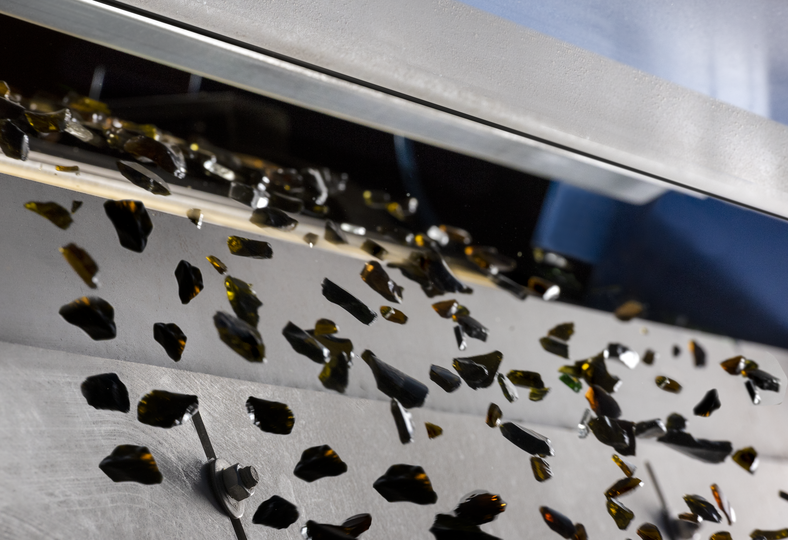

To effectively recycle plastic, glass, or metal, it's crucial that the collected materials maintain a high level of purity. Our separation and sorting systems ensure that contaminants are precisely removed or material streams are divided into pure fractions, enabling efficient and cost-effective recycling.

Separation and sorting systems are designed to ensure high material throughput while minimizing valuable material loss. Precise separation and sorting maximize efficiency in further processing.

Our systems enable recycling rates of up to 100% for glass and certain plastic applications.

Ready to maximize the value of your recyclable materials?

Sesotec is your solution!

YOUR INDUSTRY.

Cutting-Edge Recycling Technology for Every Industry.

Our solutions empower the entire recycling industry to achieve greater sustainability, environmental protection, and profitability.

Recycle more, recycle better.

220

Millions of Tons

of plastic waste generated globally in 2024.

70

Millions of Tons

of plastic waste ended up in the environment in 2024.

Unlock the Full Potential of Your Materials with Sesotec. Boost Profitability and Sustainability.

Source: Earth Action

Sort them out.

- Plastics

- Glass

- E-Waste

- Household Waste

- Metal

Our sorting systems identify and separate plastics like PET, HDPE, and PVC based on their unique chemical and physical properties. Plus, our technology ensures precise color sorting and the removal of metals and other contaminants.

We sort white, green, and brown glass, flat and hollow glass, as well as specialty glass (e.g., heat-resistant glass, leaded glass, screen glass, PV panels, etc.)

PCBs, cables, wires, copper, stainless steel, aluminum, or other electrical components: Our systems help you reclaim valuable secondary raw materials and dispose of hazardous substances responsibly.

Whether it's plastics, paper, cardboard, beverage cartons, glass, wood, or metal—our sorting systems reliably separate the mixed materials found in household waste.

Whether it's steel, scrap iron, zinc, aluminum, or copper – we ensure efficient sorting and impurity separation in metal recycling.

Profitable Circular Economy

Our resources are limited, making recycling more crucial than ever. Nearly every other trade and consumer goods company relies on resource availability and views recycling as a key to greater sustainability.

OUR TECHNOLOGIES POWERING THE RECYCLING INDUSTRY

Cutting-Edge Recycling for Maximum Value Creation.

Our diverse range of equipment empowers the recycling industry with cutting-edge detection, separation, and sorting technologies. Ensure product quality, maximize system uptime, and produce premium recycled materials. All from a single source!

- SORTING SYSTEMS

- MATERIAL MANAGEMENT SYSTEMS

- MAGNETIC SYSTEMS

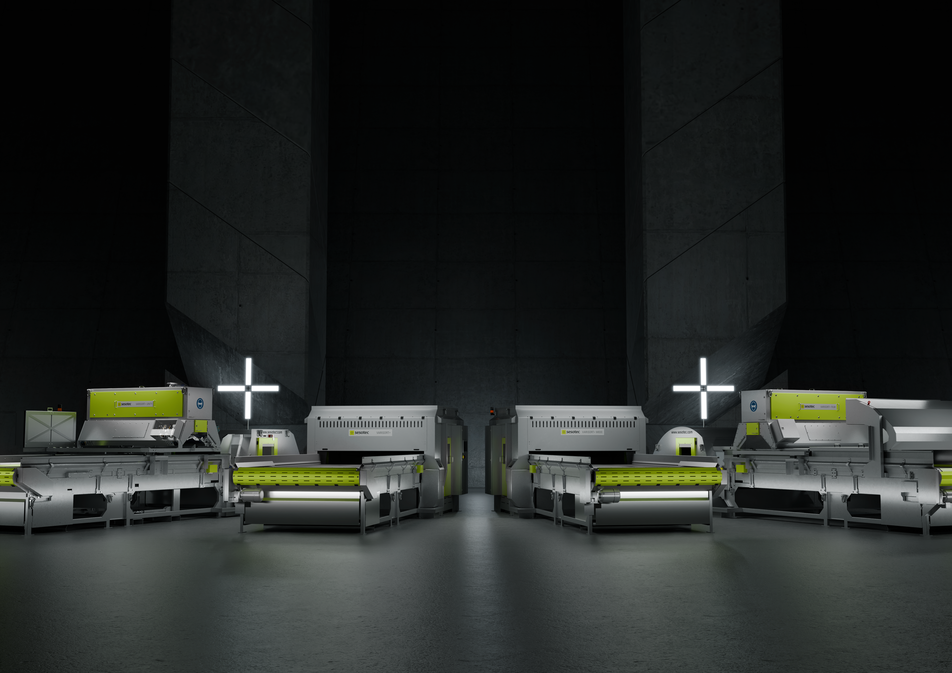

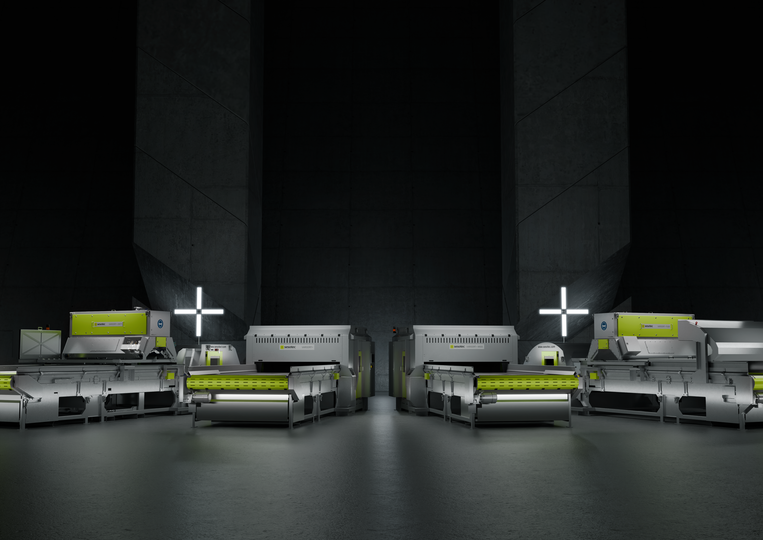

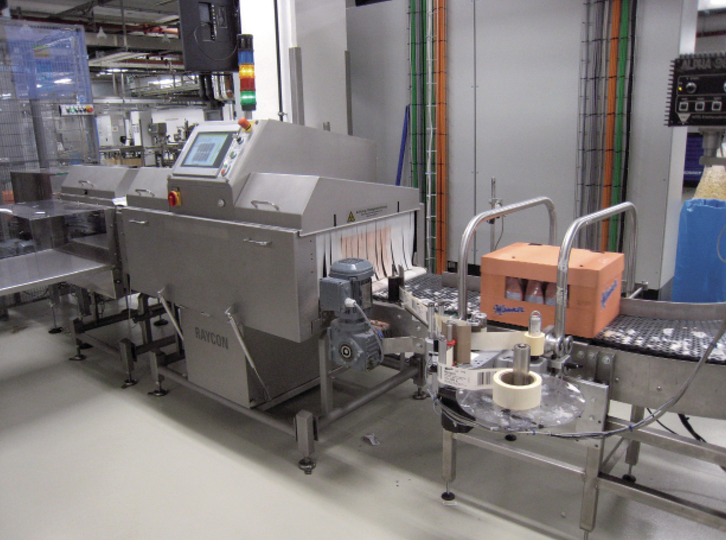

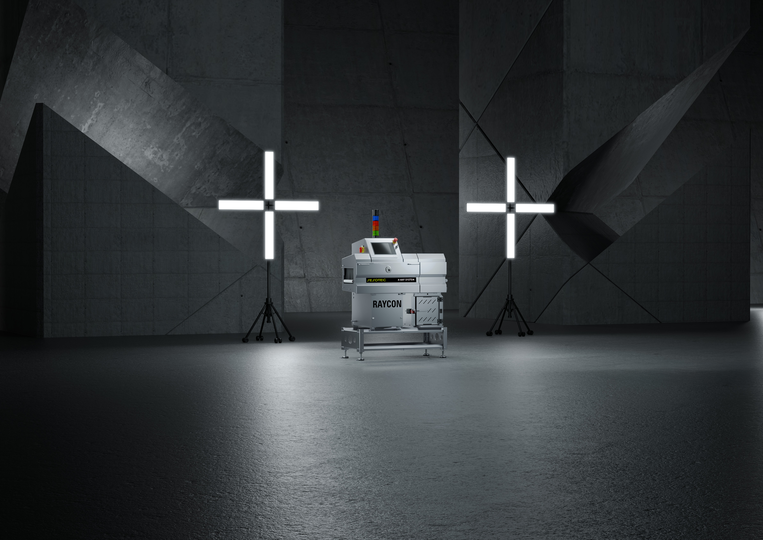

Sorting Systems

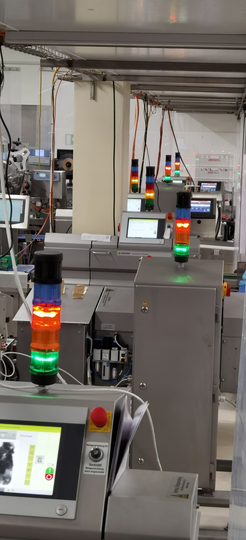

Our sorting machines are modular by design: Depending on your needs, we can integrate various sensors, detectors, and separators into a single device. Unwanted materials are precisely removed from the material flow in milliseconds using separation systems like air jets and flaps.

READ MORE

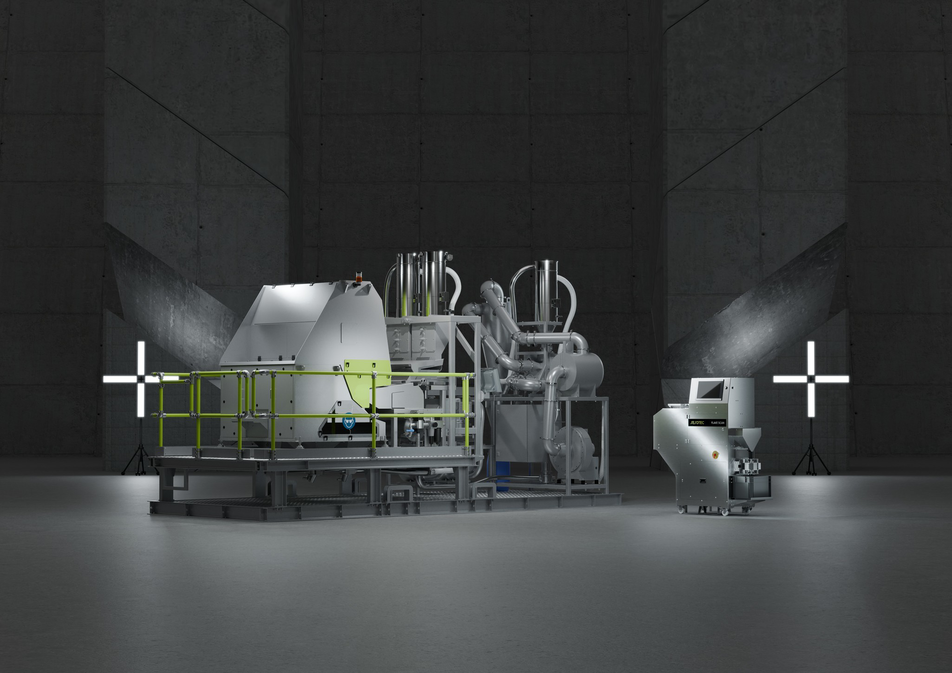

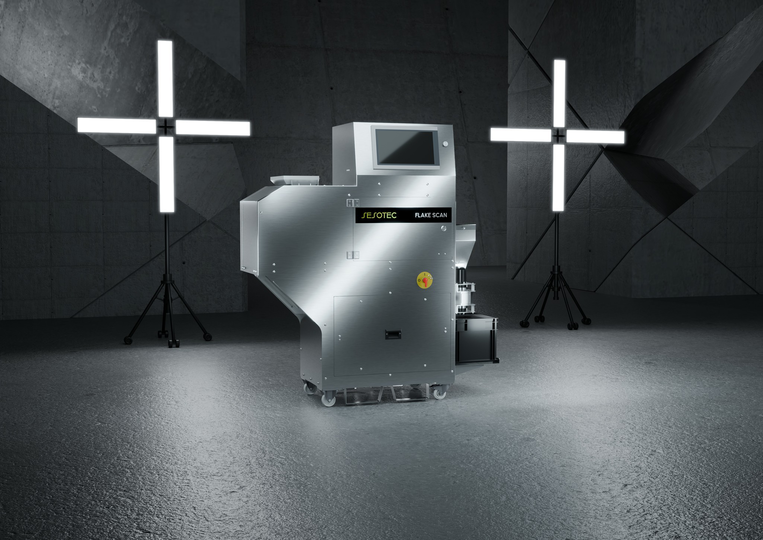

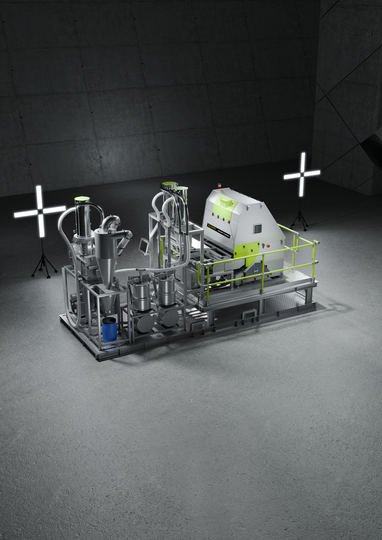

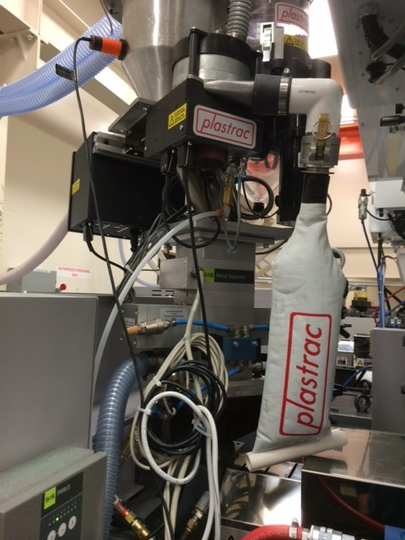

Material Management Systems

The PRE-SORT and FLAKE SCAN sorting systems empower plastic processors with customizable sorting processes and rapid sample analysis by plastic type, color, and metal foreign bodies. Achieve high-quality, pure materials and cost-effective production.

READ MORE

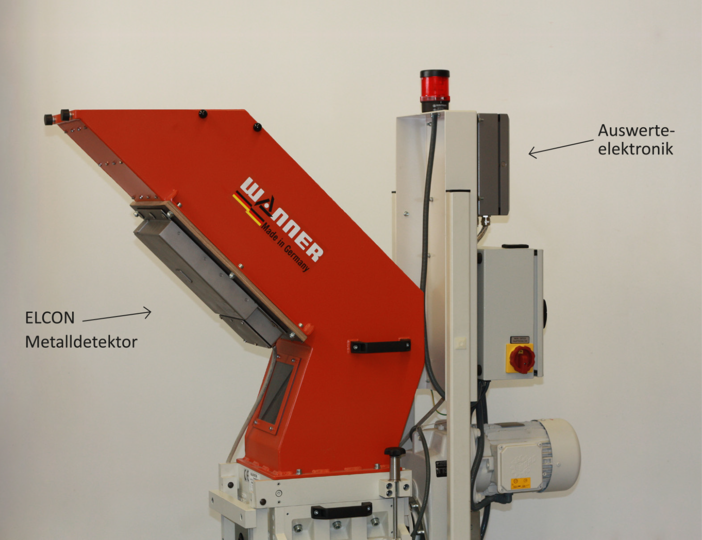

Magnetic Systems

Our magnetic systems deliver exceptional magnetic performance and efficient design to remove even the finest ferrous metal contaminants. Strategically arranged magnetic rods achieve maximum separation efficiency. They integrate easily and quickly into piping systems, hoppers, or directly at material inlets—even in existing production lines.

READ MORE

ADD-ONS & SERVICES

Smart Enhancements for Unmatched Performance

Unlock actionable insights from process data to boost the efficiency of your sorting and recycling operations and minimize downtime. VISUDESK, the visualization software for sorting machines and systems, brings transparency to your sorting processes with process data, enabling direct control for enhanced efficiency and profitability.

Enhance Clarity in

Your Sorting Processes

Unleash Total Control

Over Your Sorting Systems

Boost Profitability with

Data-Driven Optimization

Smarter Than Ever: AI in Recycling

Sesotec partners with Blue Competence.

As a global leader in product inspection and recycling technology, we embrace our responsibility to champion resource conservation and environmental protection. That's why we proudly partner with the sustainability initiative Blue Competence (www.bluecompetence.net).

Blue Competence, an initiative by VDMA (www.vdma.org), aims to advance sustainability in mechanical and plant engineering while promoting the industry's sustainable solutions. Through our partnership, we commit to upholding the 12 sustainability principles of mechanical and plant engineering (www.bluecompetence.net/about).

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)