EFFECTIVE FOREIGN BODY DETECTION FOR NUTRIENTS AND SEASONINGS

Spice Without Foreign Bodies

Purity is a crucial quality factor in the production of nutrients and seasonings. Consistent foreign body detection is therefore a must. Sesotec detection systems are specifically designed to meet the demands of the nutrient and seasoning industry. They reliably detect even the smallest contaminants in spices, powders, and nutrients, safeguarding your production processes from potential risks – ensuring the purity your customers expect.

The Most Common Foreign Bodies in Nutritional and Seasoning Products

Metal Wear

Even tiny metal particles from machine wear can cause injuries if ingested or damage sensitive equipment.

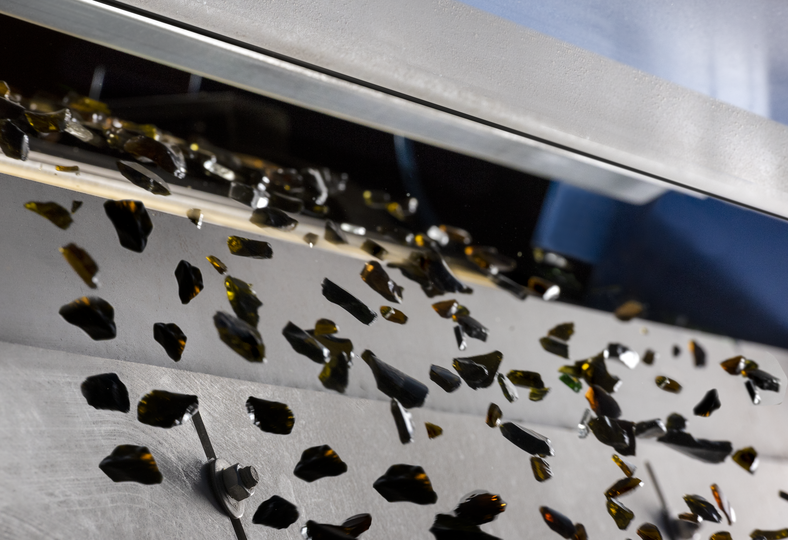

Shattered Glass

Identify and remove glass shards from broken lighting or containers to prevent injuries.

Stones

Stones can inadvertently enter the production process during raw material processing.

Operator Items

Foreign bodies like pens, hairpins, or gloves must be detected and removed to prevent injuries and contamination.

Metal Wear

Even tiny metal particles from machine wear can cause injuries if ingested or damage sensitive equipment.

Shattered Glass

Identify and remove glass shards from broken lighting or containers to prevent injuries.

Stones

Stones can inadvertently enter the production process during raw material processing.

Operator Items

Foreign bodies like pens, hairpins, or gloves must be detected and removed to prevent injuries and contamination.

Do you have foreign bodies in your nutrients and seasonings?

Technology That Inspires Trust

- X-ray Inspection

- Metal Detection

- Magnetic Systems

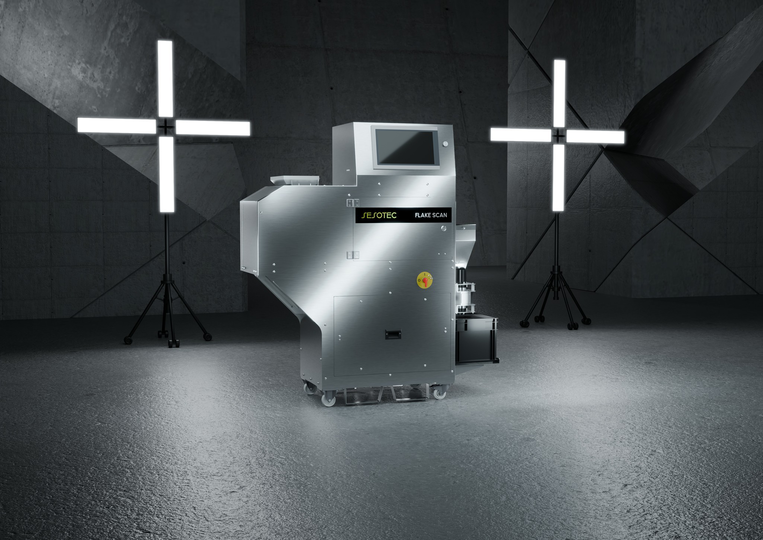

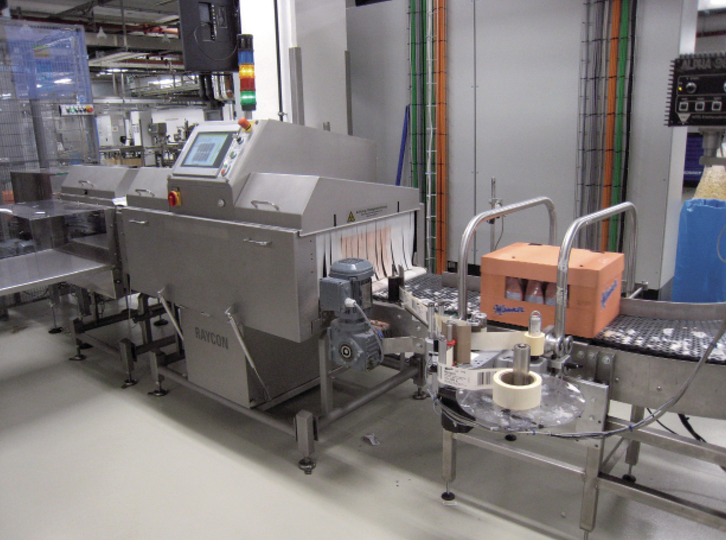

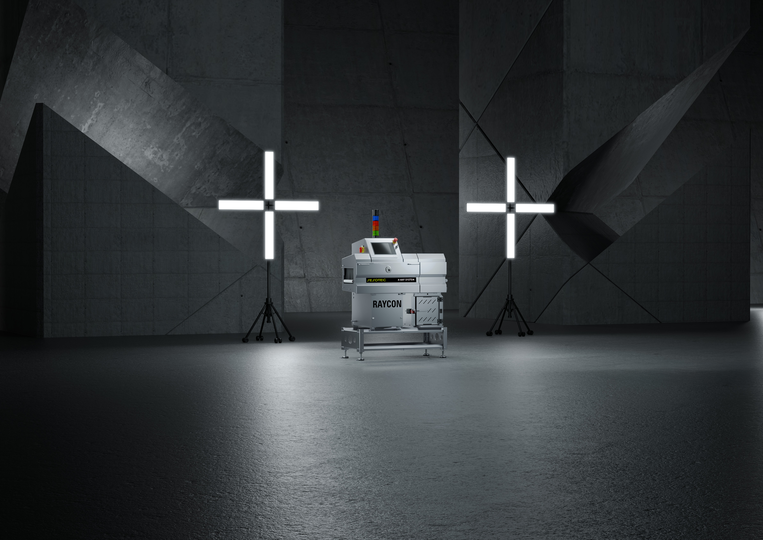

X-ray Inspection

Our X-ray inspection systems ensure the ultra-precise detection of foreign bodies like stones, metal shavings, glass shards, plastic, or wood during the production of nutrients and seasonings.

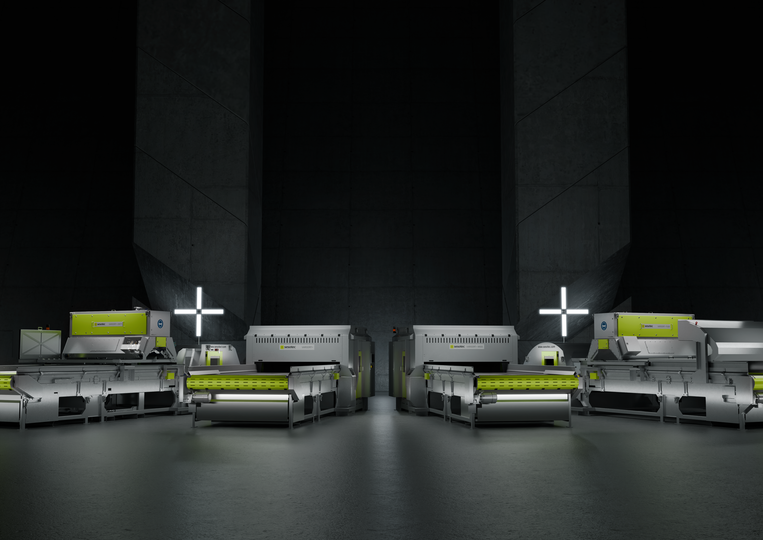

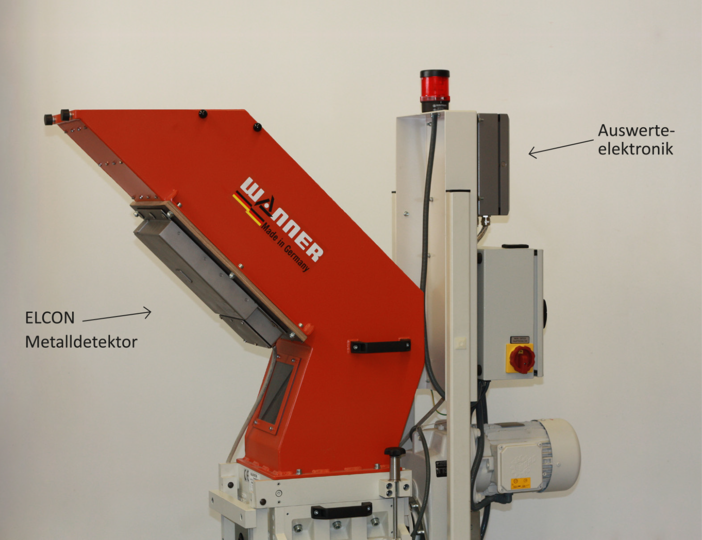

Metal Detection

Sesotec metal detection systems reliably identify metallic contaminants in nutrients and seasonings.

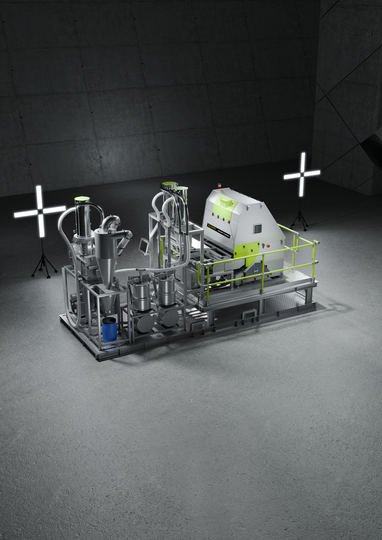

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from food and spices.

Where do manufacturers of nutrients and seasonings use Sesotec equipment?

Our foreign body detection systems are utilized across a wide range of applications.

Here are some examples of products that can be inspected:

Salt

Since salt is often processed in large quantities, even small foreign bodies can contaminate the entire batch and damage equipment. Foreign body detection ensures purity and process reliability.

Sugar

Due to its static nature, sugar easily attracts foreign bodies. Careful detection is crucial to ensure quality and protect consumers.

Spice Blends

Spices are delicate and often used in their pure form. Foreign bodies can not only alter the taste but also compromise the product.

Baking Agents

Consistency is key in baking ingredients. Even the smallest impurities can affect the final product. That's why foreign body detection is essential for maintaining consistent quality.

Ready-to-Drink Tea/Coffee

Foreign bodies in ready-to-drink tea and coffee products threaten safety and quality. Precise detection ensures purity and pure taste.

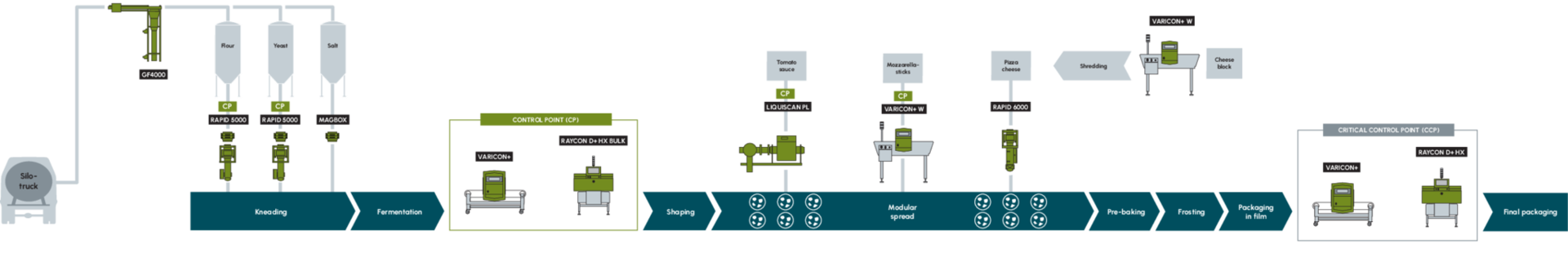

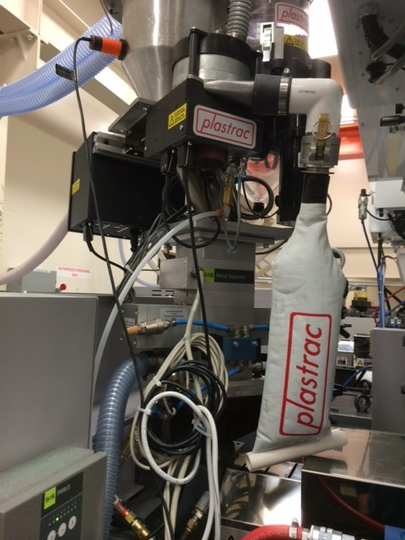

Across the Entire Production Line

From goods receipt to production to dispatch – our metal detection and X-ray inspection systems ensure maximum product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution with Ease:

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

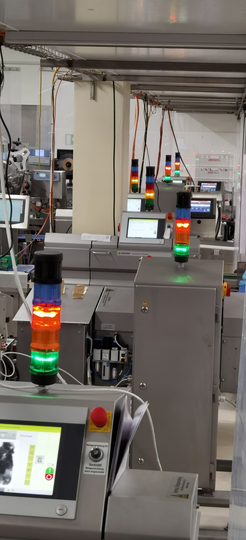

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of producing nutrients and seasonings.

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor in the production of nutritional and seasoning products, especially when it comes to certifications and audits. Reliable foreign body detection plays a key role in maintaining hygiene standards and meeting quality requirements according to international standards like IFS or BRC.

LEGAL REQUIREMENTS

Laws like the EU Regulation 178/2002 and national food laws require nutrient and seasoning manufacturers to implement effective measures to prevent food contamination by foreign bodies. Failure to comply with these regulations can lead to consequences such as recalls, fines, or the revocation of operating licenses.

CUSTOMER REQUIREMENTS

Customers demand the highest level of product safety and quality from nutrient and seasoning manufacturers. Consumers and trade partners increasingly require guaranteed standards, and even the slightest contamination can permanently damage brand trust.

PROTECTION AGAINST RECALLS AND DAMAGES

Producers of nutritional and seasoning products must minimize all risks of recalls, reputation damage, and legal consequences.

Sesotec offers the most effective and efficient method to ensure your product is free from foreign bodies and contaminants.

Explore Case Studies

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)