For over 30 years, Steinbeis Polyvert GmbH (formerly Kruschitz GmbH) has been dedicated to providing the perfect solutions for recycling valuable secondary raw materials. Founded in 1956 with production facilities in Austria and Germany, Steinbeis Polyvert is one of Europe's leading plastic recyclers. Our recycling solutions for PET, HDPE, and PP plastics are continuously developed and optimized at Steinbeis Polyvert.

The result is top-quality plastic granules that can be used in a wide range of product applications. With an extensive international network and years of expertise in plastic recycling, Steinbeis Polyvert offers its clients an optimal product portfolio.

The primary goal is to sustainably recycle diverse material streams to provide the highest quality recyclates. This approach enhances the circular economy, conserves resources, and contributes to environmental protection.

The Challenge: Sorting Diverse Materials

If you need to sort a wide variety of materials, you require flexible, high-precision sorting technology tailored to both upstream and downstream processes. Sesotec was involved from the start in planning the new sorting line. After extensive sorting trials with different material compositions at the Sesotec Technical Center in Schönberg, Bavaria, the sorting processes were collaboratively developed and successfully implemented.

The Solution: Sorting and Analysis Systems by Sesotec

At Steinbeis Polyvert, material processing kicks off with bale breaking. After removing ferrous metals, air classification, and ballistic separation, the real sorting begins, dividing materials into pure fractions.

The cutting-edge Sesotec sorting systems, VARISORT+ UNITY, handle both the preliminary sorting and final cleaning of the material. They also recover materials from previously generated reject fractions.

Depending on the incoming material, different sorting programs are selected and optimized during commissioning. A standout feature is the Sesotec VARISORT+ FLEX bridge solution, which enables online analysis of incoming materials from pre-processes. This occurs alongside the ongoing sorting program, providing real-time insights into the material's composition and color. The statistical process data generated allows for quick adjustments to changes in material composition, maximizing the efficiency of the sorting program.

The sorted material fractions are then ground and washed. The flakes proceed through additional separation stages to the final optical sorting phase, where Sesotec's FLAKE PURIFIER+ systems come into play. These systems remove off-colors, foreign plastics, and residual metals, ensuring pure PP and HDPE flakes.

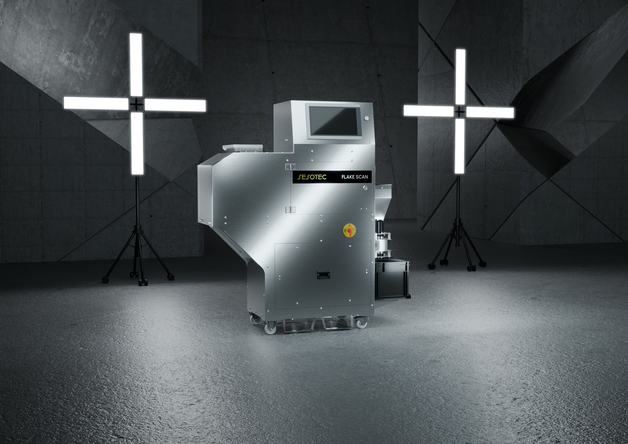

To meet the high-quality standards of processors, Steinbeis Polyvert employs Sesotec's FLAKE SCAN analysis system before extrusion and at other sorting stages. This system evaluates the quality of plastic flakes in minutes, enabling rapid, reliable decisions on material usability. Samples are precisely analyzed for foreign plastics, off-colors, and metals, with results delivered swiftly.

In the final step, the plastic flakes are extruded on-site into plastic granulate. This ultra-pure recycled granulate is used by plastic processing companies to produce new products. The recycling loop is complete.

Customer Benefit: Meeting the Highest Quality Standards

At Steinbeis Polyvert's Austrian facility, we're pioneering the use of the latest Sesotec multi-sensor sorting systems, enhanced with artificial intelligence (AI). These VARISORT+ UNITY systems with measurement bridges represent cutting-edge technology, elevating sorting capabilities to new heights.

Sesotec's AI-powered sorting systems excel at detecting black objects on black conveyor belts and distinguishing materials that traditional color evaluation struggles to differentiate.

Achieve outstanding results with our three-chute device, featuring an ultra-fine nozzle grid. This device enables sorting into three material fractions on a single sorter, even with very small material grain sizes.

André Aßmann, Managing Director of Steinbeis PolyVert GmbH: “With Sesotec, we have a reliable technology partner that supports our recycling processes with flexible and precise sorting and analysis systems, meeting the highest quality standards of our customers.”

Download this case study as a document.