Reiling represents over a century of expertise in material collection and recycling. As a trusted partner for industries, municipalities, businesses, and dual systems, this family-run recycling company excels in collection, transport, processing, and delivering high-quality recyclates. Reiling operates plastic recycling facilities in Marienfeld, Hamm, and the new site in Burgbernheim.

The Challenge: Only pure PET flakes can be sold profitably

With new regulations increasing the collection of PET bottles, comprehensive service is becoming more crucial than ever. Reiling offers a full spectrum of solutions: from collection (whether full-service or DIY), through processing (transforming bottles into flakes), to meticulously controlled end products.

At Reiling Kunststoff Recycling, PET bottles are delivered either as briquettes or bales. Before entering the processing facility, the bottles are first separated. Contaminants are then removed, and the bottles are sorted by color. Following shredding and washing, the flakes undergo another cleaning via a sorting device. For our flake buyers, color and purity are key to providing a premium raw material for new product creation.

The Solution: From Bottle to Flakes with Premium Sorting Technology

Reiling Kunststoff Recycling leverages cutting-edge technology for the efficient processing of PET flakes, ensuring customers receive premium-quality flakes with exceptional color purity.

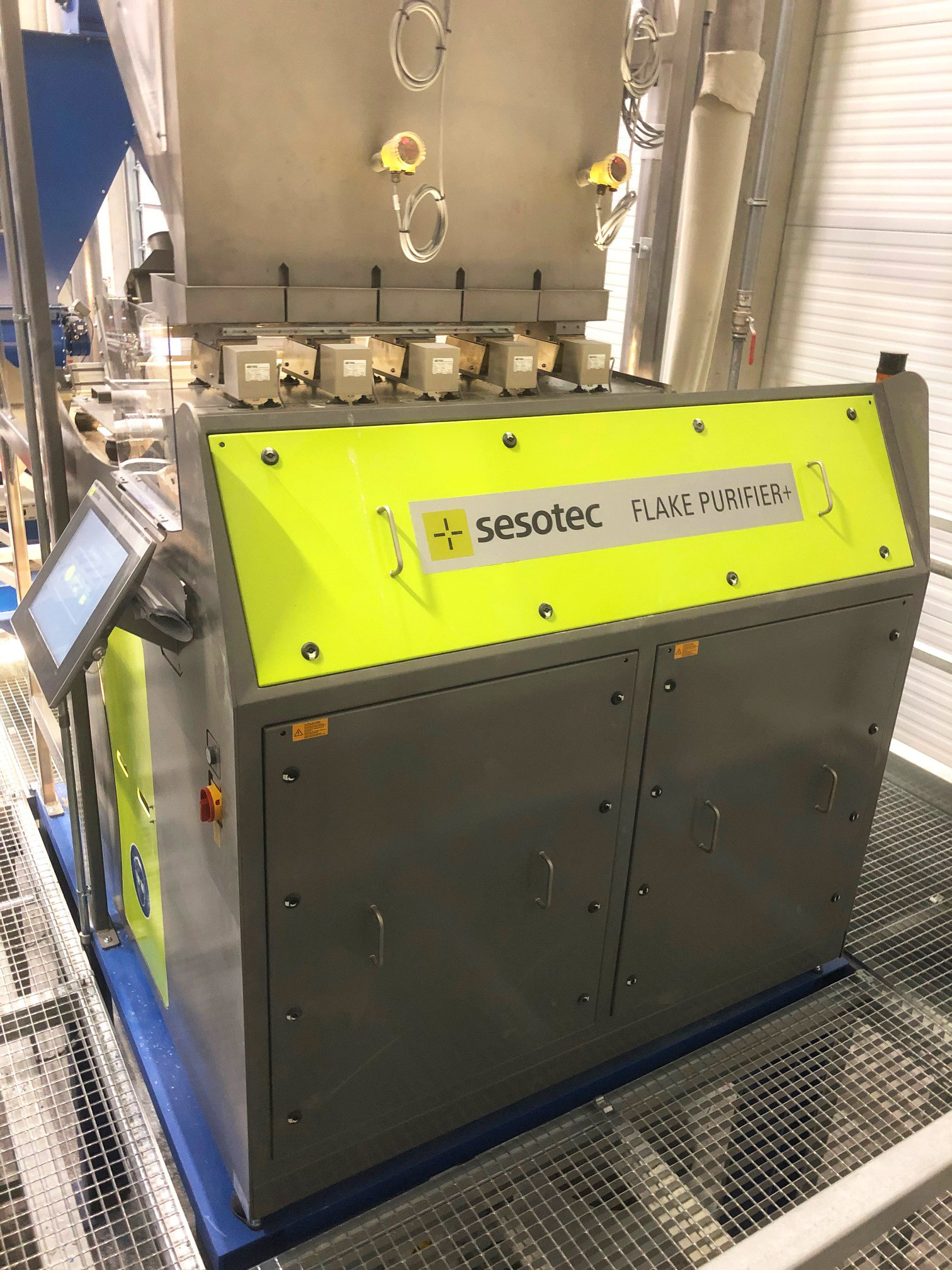

At the heart of the recycling process are the FLAKE PURIFIER+ sorting systems from Sesotec, designed for PET flake sorting. These systems are equipped with advanced sensors that enable single-pass separation of colors, metals, and different types of plastics.

The new generation of FLAKE PURIFIER+ is now operational at Reiling Kunststoff Recycling's Marienfeld location and their new facility in Burgbernheim.

Customer Benefit: Superior Quality with Minimal Material Loss

Beyond the optimal sorting system, Sesotec enables seamless integration into your overall setup with precise material feeding and tailored device output.

Feed hoppers deliver PET flakes to the main line of the FLAKE PURIFIER+ for sorting. The material selected from the main line is then automatically fed through a recovery line for further processing.

The big advantage: Most of the valuable material is recovered, minimizing any loss.

Andreas Schragen, Managing Director of Reiling Kunststoff Recycling, is convinced by Sesotec's comprehensive service: “At our locations, we have relied on Sesotec as a dependable and skilled partner for many years. The new FLAKE PURIFIER+ series enables a closed material loop. We can achieve flakes of the highest purity, even meeting the stringent requirements of the food industry.”

Download this case study as a document.