In the food industry, systems for foreign body inspection are indispensable to comply with food safety regulations and standards. However, in an industry where both quality requirements and the pressure for profitability are constantly increasing, the right hardware is only part of the recipe for success. Software solutions are becoming increasingly important by complementing and expanding the functionality of the hardware. In this article, we highlight the latest developments in the field of software for food safety, which are indispensable in modern food operations.

- Artificial Intelligence for Precision: By improving the detection accuracy of metals using AI methods, the reliability of detection systems can be significantly increased. Reducing false alarms due to product influences is a crucial step to enhance efficiency in processing and quality control. Additionally, excluding metallized packaging from the detection process is important to ensure more precise sorting and separation of materials.

- AI-based Visualization Software provides essential data and facts that are indispensable for process optimizations. It contributes significantly to planning security by enabling precise predictions and analyses. Furthermore, this software plays a central role in production and quality control by presenting complex information clearly, thus allowing efficient monitoring and control. Another advantage of this software is that it enables continuous learning through the use of artificial intelligence, allowing it to continuously adapt to changing conditions and thus deliver increasingly precise results.

- Intelligent Documentation Software enables seamless and efficient documentation, which is essential for guideline-compliant production. The accuracy and reliability of production processes are significantly improved. Another key aspect of intelligent documentation software is that it reduces or even eliminates the need for manual tests. This leads to significant time and resource savings, as automated processes increase efficiency while minimizing the risk of human errors.

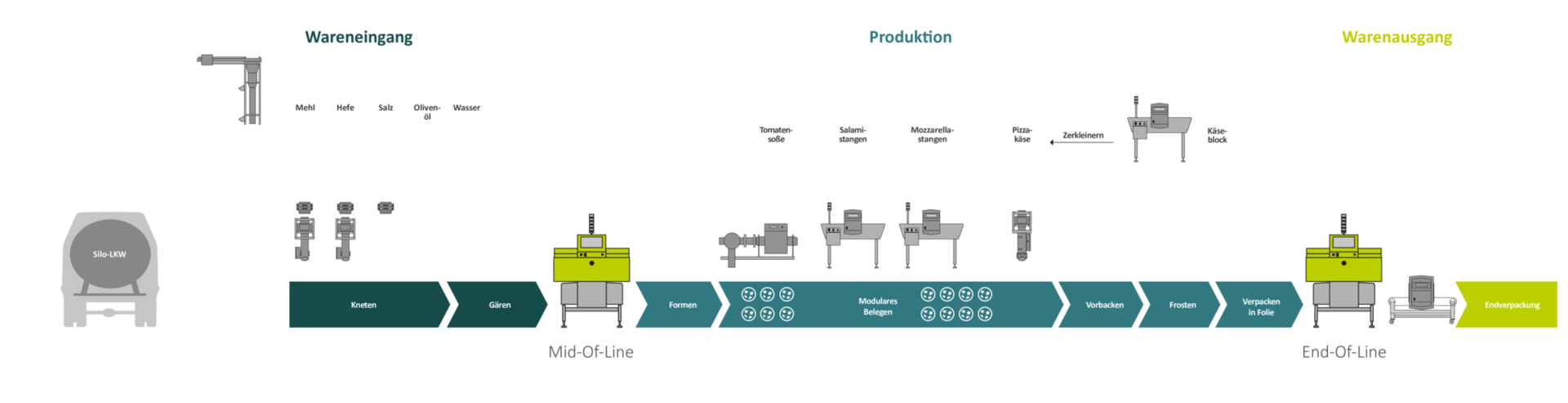

- Connectivity and Real-time Analysis: Modern software enables comprehensive connectivity of all machines and systems, seamlessly networking the entire production process from goods receipt to goods dispatch. This integration allows for real-time analysis of the captured live data. The combination of networking and instant analysis allows for proactive intervention, which not only minimizes downtime but also significantly increases overall equipment effectiveness.

Why software solutions for food safety are important:

- Traceability: Software solutions enable precise traceability of food along the entire supply chain. From farm to table, companies and authorities can trace the origin of food and respond quickly and efficiently in the event of a recall.

- Data analysis and early warning systems: Modern software solutions use advanced analytical techniques to process large amounts of food safety data. This allows early warnings of potential hazards to be issued, preventing quality losses or threats to food safety.

- Quality control and compliance: Software solutions enable efficient monitoring of compliance with quality standards and legal regulations. They automate controls and audits, facilitate documentation, and help identify deviations. This allows companies to ensure that their products meet the highest quality and safety requirements.

- Efficiency improvement: The automation of processes in the food industry through software solutions contributes to increased efficiency. This not only means cost savings but also a reduction in human or machine errors that often lead to food contamination.

- Precaution and prevention: Through continuous monitoring and analysis of data, software solutions can help identify potential risks early and take preventive measures to prevent food contamination and scandals.

- Optimization of the value creation process: Through seamless monitoring and networking of all control points, from goods receipt to goods issue, both critical and non-critical control points, the value creation process is significantly improved. Software solutions thus ensure holistic control and efficiency improvement throughout the entire production process.→ Foreign body control "End-of-line” is good - "Along the line" is better.

- Last but not least - Customer transparency: Consumers are becoming more demanding and want to know more about the origin and quality of their food. Software solutions enable companies to create transparency in the supply chain and provide consumers with detailed product information. This strengthens confidence in food safety.

Conclusion

Software solutions are a crucial factor in ensuring food safety. They help companies monitor and optimize processes and meet the requirements of consumers and authorities. By combining high-tech hardware, intelligent software, comprehensive documentation, sustainable data management, and optimized production control, coupled with appropriate maintenance and service offerings, companies achieve predictability, control, and sustainable production. This strengthens consumer confidence while ensuring the economic efficiency of food production.