PACKAGED PRODUCTS

Make the Invisible Visible

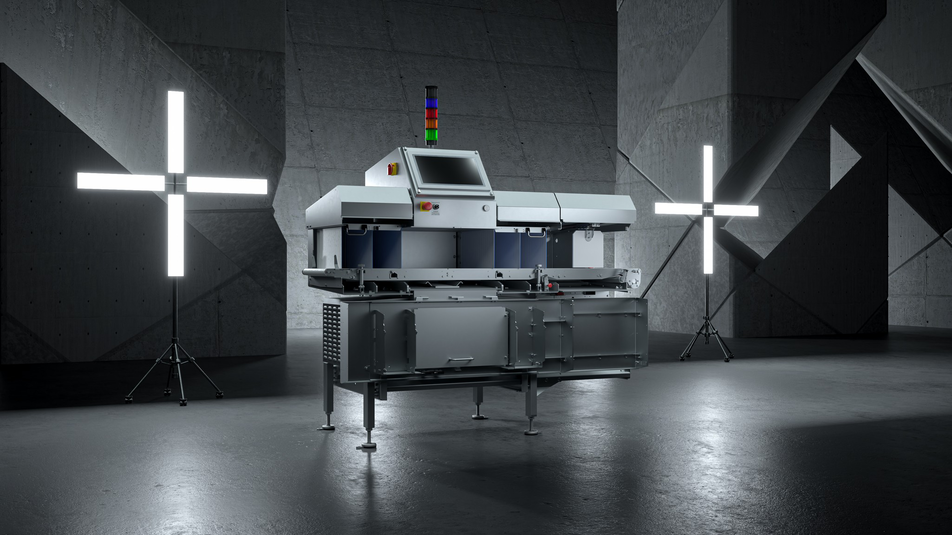

Our X-ray systems for packaged goods are specifically designed for the food industry, primarily used for final quality control.

They combine highly efficient foreign body detection with exceptional user-friendliness and hygienic design, fully compliant with all major food industry regulations.

Who Benefits from X-ray Inspection Systems for Packaged Products?

An X-ray inspection system is used in food production to detect foreign bodies, ensure product quality, and comply with legal requirements and safety standards. It identifies dense contaminants and irregularities without damaging the packaging or the product.

An X-ray inspection system is ideal for the food, pharmaceutical, cosmetics, and packaging industries.

X-ray systems detect more types of contaminants—even in metallized packaging. They are essential when you need to identify not just metal, but also other foreign bodies like glass, stone, or plastic.

Guaranteed Compliance.

Easier Than Ever

Top Priority: Radiation Protection

for People and Products

Unmatched Precision

at High Speeds

Are you interested?

We see what you don't...

- Aluminum

- Glass

- Bones

- Wire

- Stone

- Ceramics

- Rubber and Plastics

May originate from packaging materials, production machinery, or closures.

Common contamination from broken bottles, glass, or production containers.

In meat, fish, and poultry products as natural or processing-related residues.

Commonly from machine parts, sieves, or wire brushes in production.

Commonly found in raw materials like grains, vegetables, or nuts from the harvest.

Occurs due to breakage of knives, containers, or insulation materials during production.

Rubber and plastics can enter food production due to machine wear, faulty tools, packaging remnants, human error, or contaminated raw materials.

RAYCON in Detail

Hygienic Design

Easy to clean, perfect for stringent hygiene demands

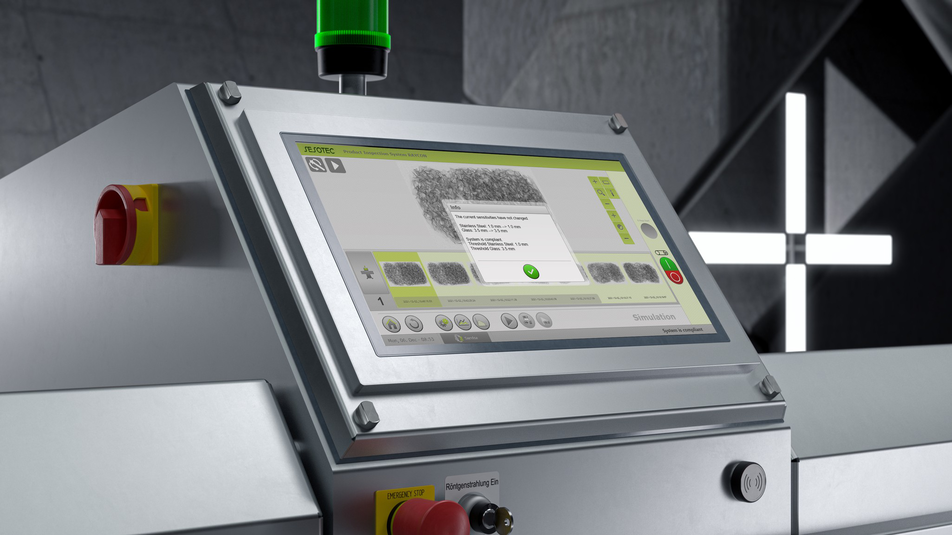

Intuitive interface with powerful software features

Touchscreen with smart features for effortless control

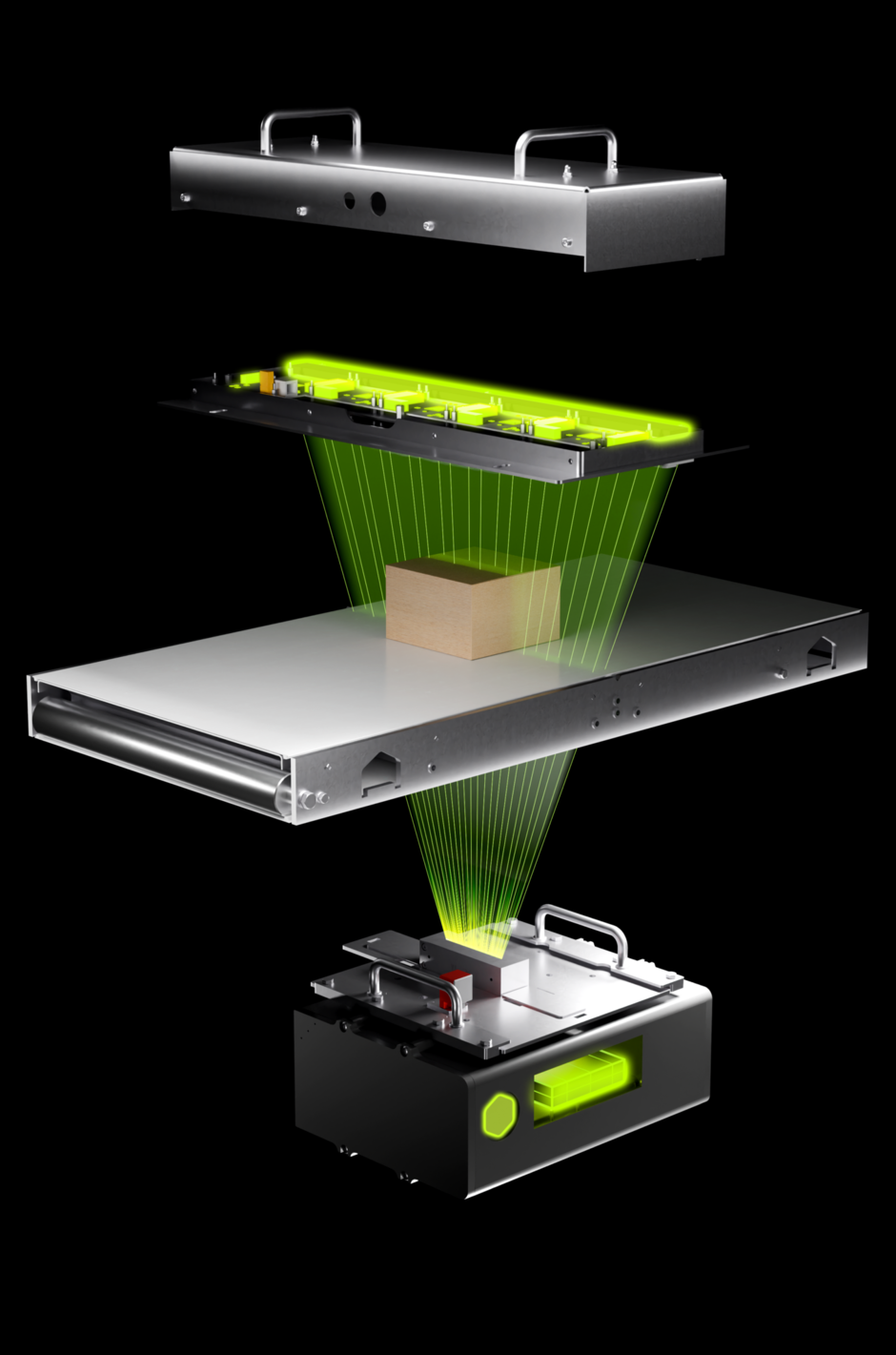

High-Speed Conveyor Belt

Fast and precise inspection even at high production rates

Modular Design

Flexible, easy to maintain, and scalable

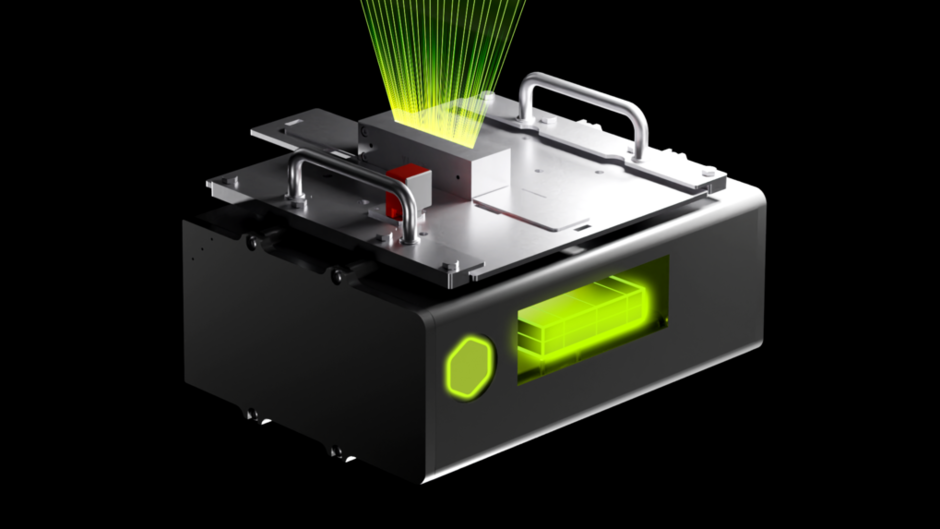

X-ray Tube and Detector Unit

Precision imaging for reliable foreign body detection.

Hygienic Design

Easy to clean, perfect for stringent hygiene demands

Intuitive interface with powerful software features

Touchscreen with smart features for effortless control

High-Speed Conveyor Belt

Fast and precise inspection even at high production rates

Modular Design

Flexible, easy to maintain, and scalable

X-ray Tube and Detector Unit

Precision imaging for reliable foreign body detection.

We deliver the perfect solution for every application—standard or customized

Durability through

Quality "Made in Germany"

10 years of parts availability,

rapid service response times

Your Priorities - Our Solutions

- Compliance

- Security

- Operation

- Hygiene

- Efficiency

- Service

Compliance and Precision

Reliable detection of metallic and non-metallic foreign bodies throughout the entire inspection area, combined with the Sesotec Compliance Package, ensures compliance with all common regulations and standards.

Safety for People & Products

High-impact radiation protection and precise X-ray usage ensure complete safety for both people and products.

Easy-to-Use Interface

With its large touchscreen, intuitive user interface, and Auto-Learn feature, RAYCON offers exceptionally easy handling.

Sophisticated Hygiene Design

Open, modular design and tool-free access to the conveyor area simplify cleaning and maintenance.

Efficiency Across All Areas

With high speeds and multi-lane capability, up to 300 products can be inspected in real-time every minute.

Reliable, Fast Service

With warranty services, a combined on-site and remote support, and targeted training, you have the optimal support for seamless operations.

0

Products per Minute0

Meters per Second0

mm foreign body size

Core Values That Inspire

High-resolution X-ray source for precise foreign body detection in products of varying densities.

Technology with an Edge

High-resolution sensors and intelligent image processing for the most precise foreign body detection in packaged products.

One Product Family – Diverse Solutions

Our X-ray Inspection Systems for Packaged Goods

Brochure

Download

Discover a comprehensive overview of all technical specifications for our X-ray inspection systems for packaged products in our brochure.

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization