Welcome to Sesotec

Driving Impact

Our intelligent solutions for foreign body detection, material sorting, and analysis empower our clients to achieve sustainable, high-quality production that benefits people, the environment, and industry. Our core brand promise, “Driving Impact,” guides everything we do. Every solution and all our efforts are meant to make a real difference, act as a driving force, and create tangible impact.

Industries

No matter the industry, a sustainable and resource-efficient circular economy must also be profitable. Discover the solution for your sector.

Curious? Book your free consultation now!

Discover What Drives Us. The Sesotec Blog

- KNOWLEDGE

- NEWS

- CASE STUDIES

- INSIGHTS

Our expert articles deliver in-depth insights into trends, technologies, and developments in the food, plastics, and recycling industries. Perfect for those who want to grasp what drives our sectors.

Discover the latest updates from Sesotec – from product innovations and trade show appearances to company events and awards.

Discover how our clients worldwide leverage Sesotec systems to ensure quality, optimize processes, and achieve sustainable success.

Discover the people, ideas, and values that define Sesotec. Personal stories, exciting projects, and genuine insights into our company culture.

Customer Testimonials

- Backwelt PILZ GmbH

- SITRAPLAS

- Mission PET

“Since implementation, we've avoided many foreign body complaints, as even the smallest contaminants like stones are sorted out. […] This is our advantage: More security for us as a company and for our customers.”

Johannes Pilz, Managing Director of Backwelt PILZ GmbH

“Thanks to Sesotec's metal separators, our complaint rate for metallic contamination is zero. Equipment availability has significantly increased, enabling the risk-free use of recyclate.”

Tim Hencken, Managing Director SITRAPLAS GmbH

"Our mission is to provide our clients with sustainable, food-grade rPET granulate. Sesotec's multi-sensor sorting systems ensure optimal decontamination and material purity for us and our customers."

Markus Huemer, CEO of Mission PET GmbH

Cutting-Edge Systems for Diverse Applications

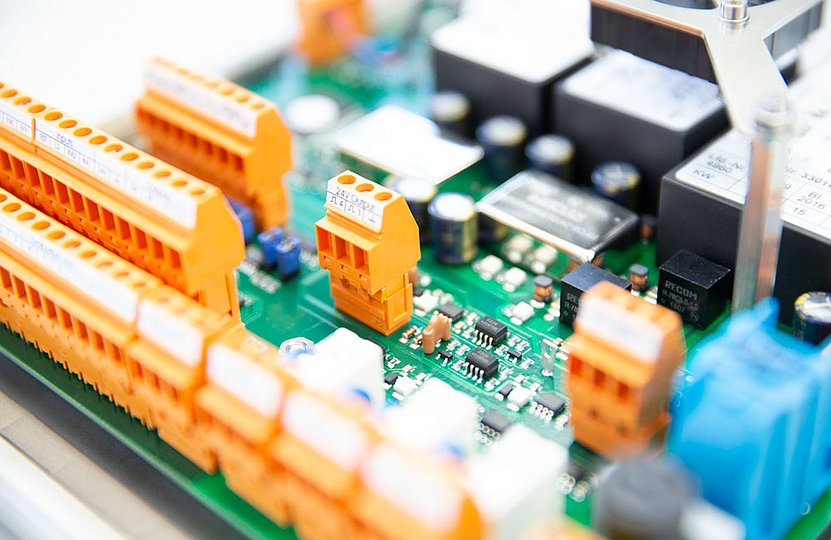

Whether the contamination is from iron, steel, stainless steel, or non-ferrous metals like aluminum, copper, and brass, whether it is exposed or embedded in the product: Our metal detection systems identify all metallic foreign bodies using inductive technology.

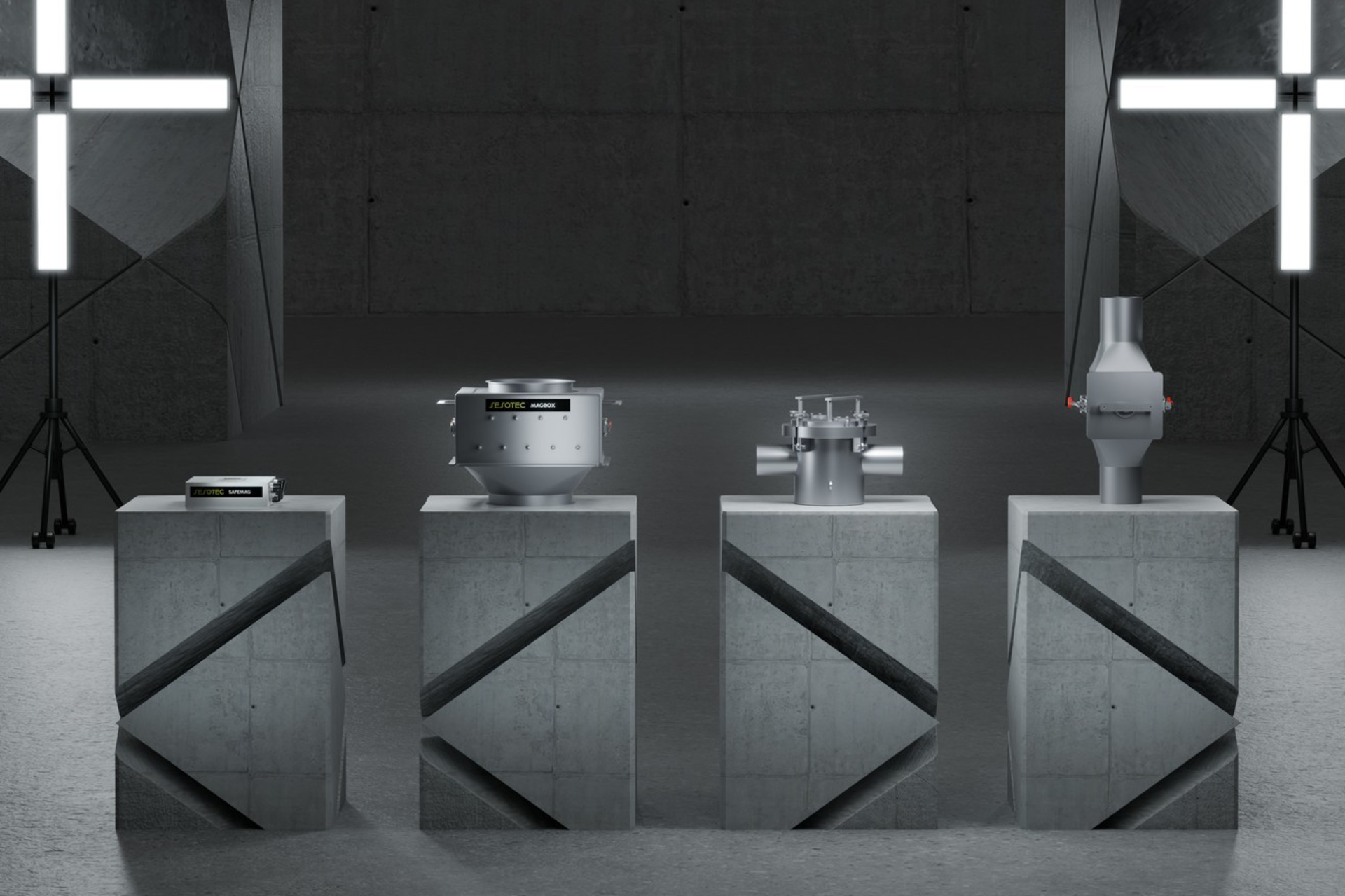

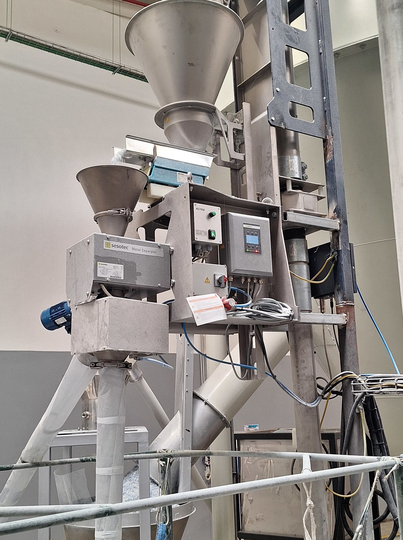

Our magnetic systems serve as effective and cost-efficient stand-alone solutions—precisely tailored to industry sectors, material types, production stages, and conveyor systems like free-fall chutes, pipelines, or conveyor belts. They can also be positioned upstream to relieve subsequent detectors, separators, or sorting systems.

.

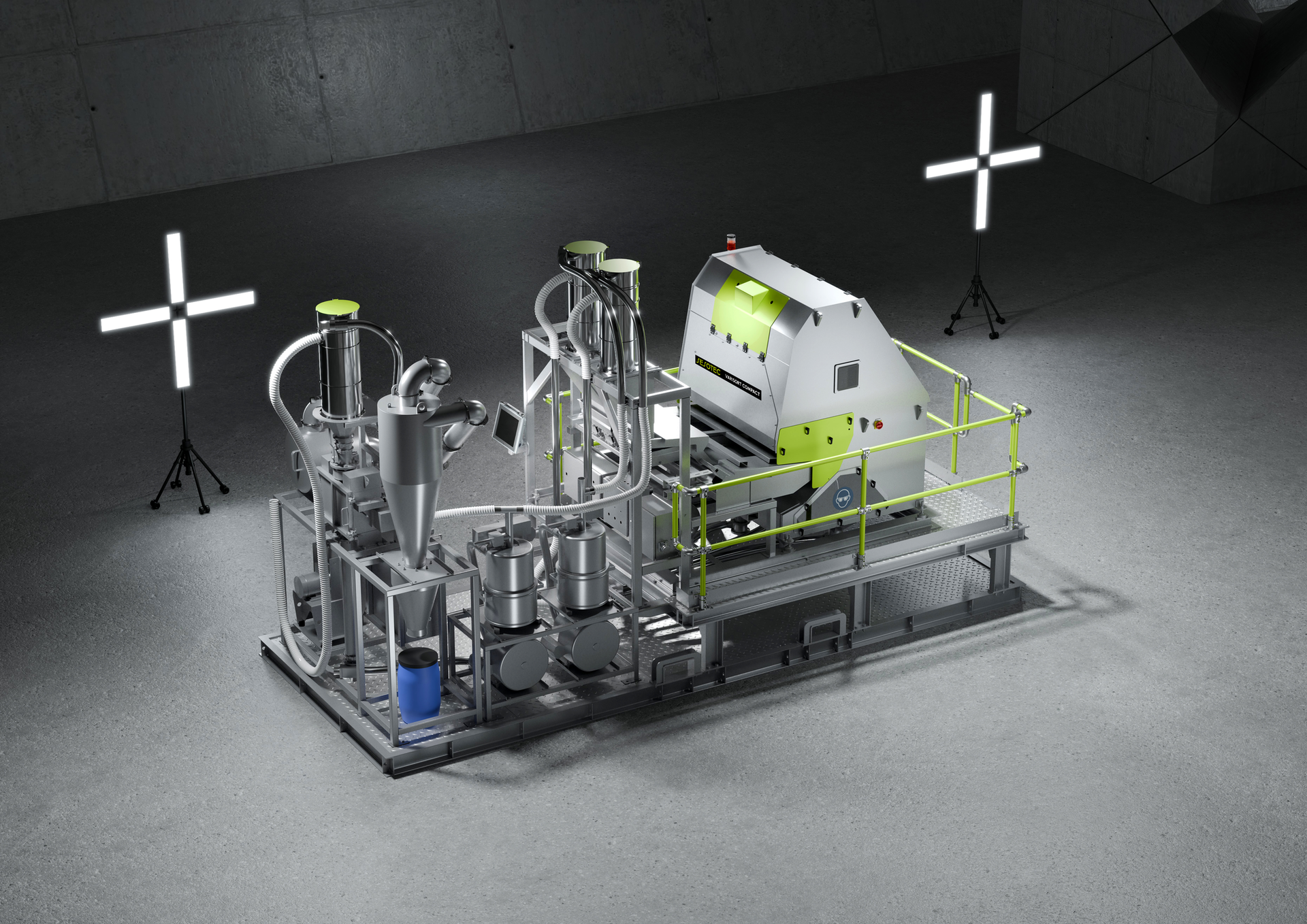

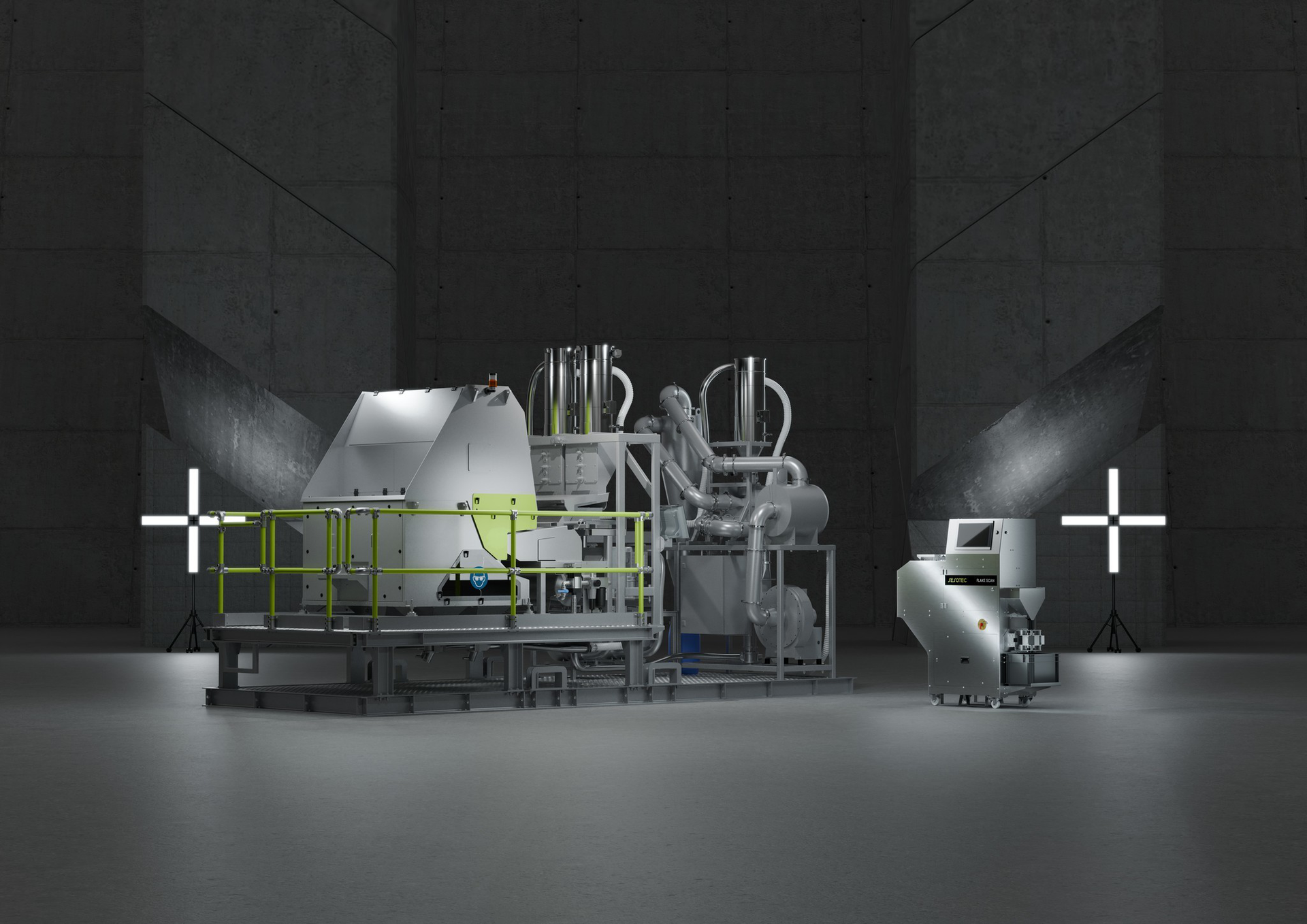

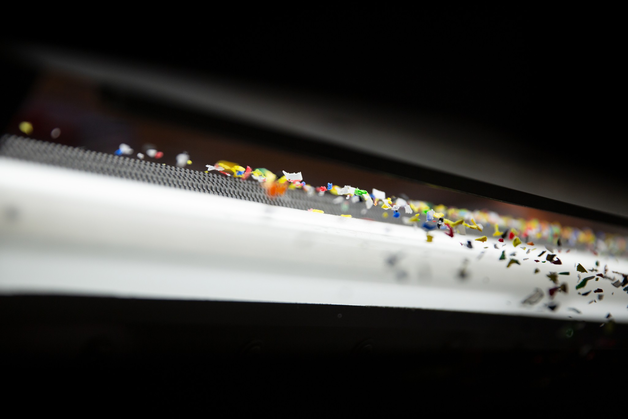

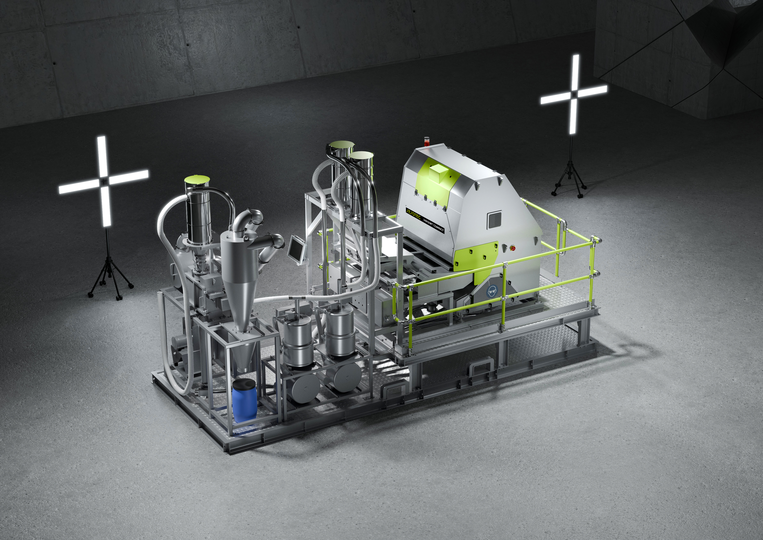

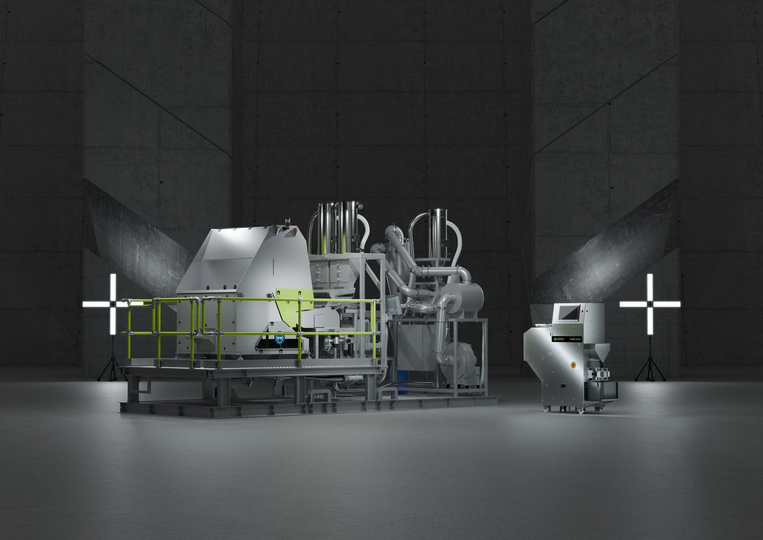

Sesotec is a leading specialist in industrial sorting for the recycling industry. We cover the full spectrum of contaminant separation and material stream sorting: from equipment systems for coarse sorting tasks to highly sensitive particle separation. In addition to standard solutions, we also develop customized complete solutions.

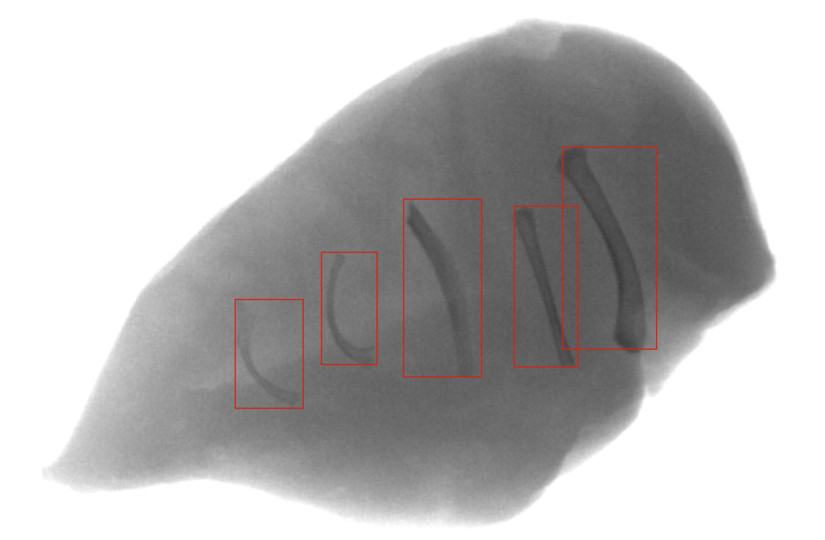

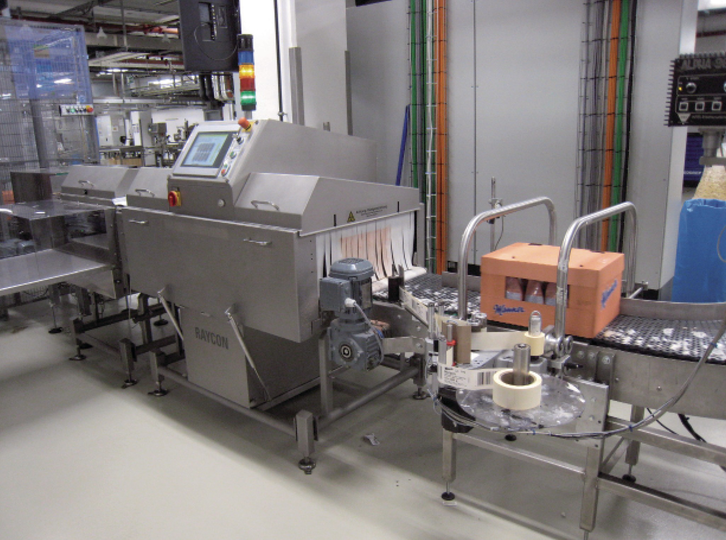

In the food industry, product quality is paramount. Manufacturers are liable for foreign body contamination, and impurities and quality defects lead to reputational damage. Food X-ray inspection offers a non-invasive solution to prevent this.

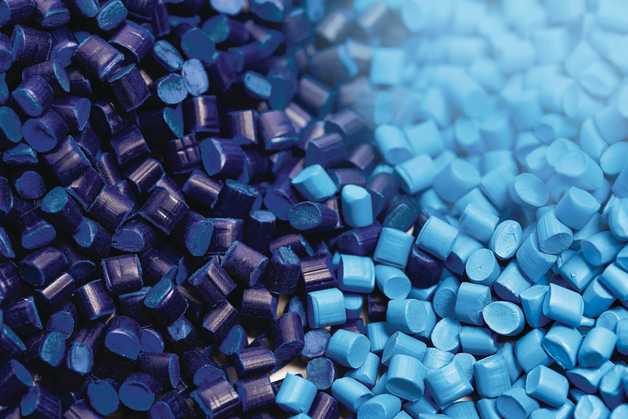

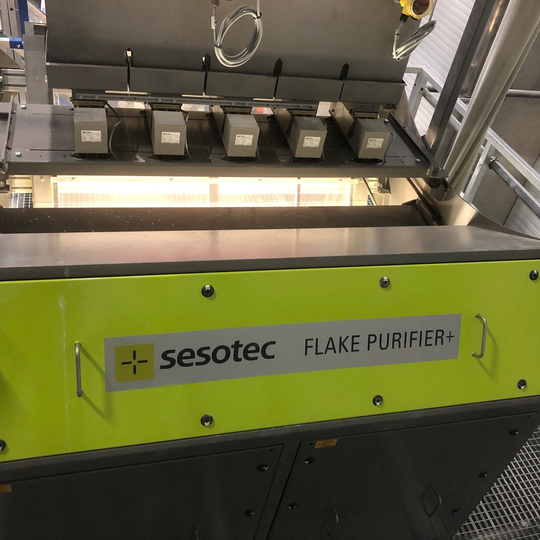

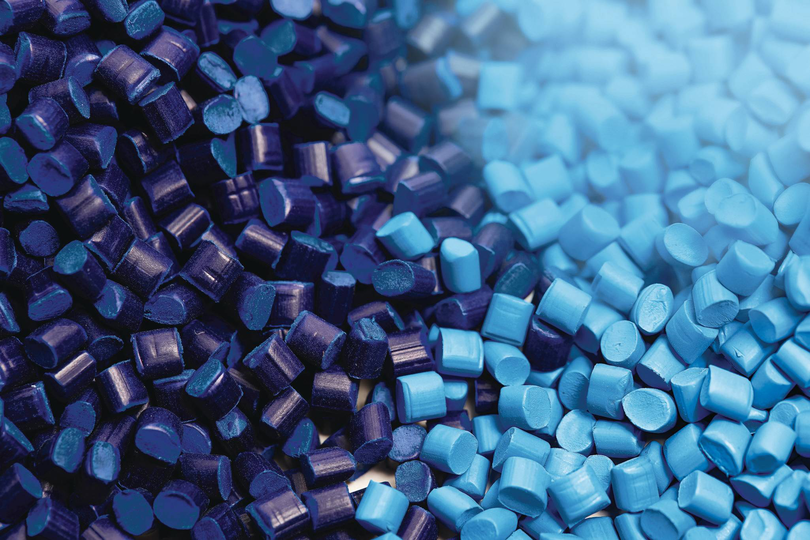

Our systems deliver top-tier detection, sorting, and analysis of plastic flakes and regrind. Whether you need precise material analysis to identify plastic types and contaminants or reliable presorting for optimal recycling processes, we have the solution.

Accelerate Together

- CAREER OPPORTUNITIES

- THIS IS SESOTEC

Whether you're a team lead or a recent graduate, explore our latest job openings across all departments here.

Since 1976, Sesotec has been crafting innovative solutions for foreign body detection and material sorting, driven by a passion for quality, sustainability, and technological excellence. Discover more about our values, history, and vision for a responsible future.

Sesotec News

Stay informed with the latest updates and insights about our products and company.

.JPG)

.JPG)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpeg)

.JPG)