Recycling

01/08/2017 |

PET Flake Sorting Station Completely Provided by Sesotec

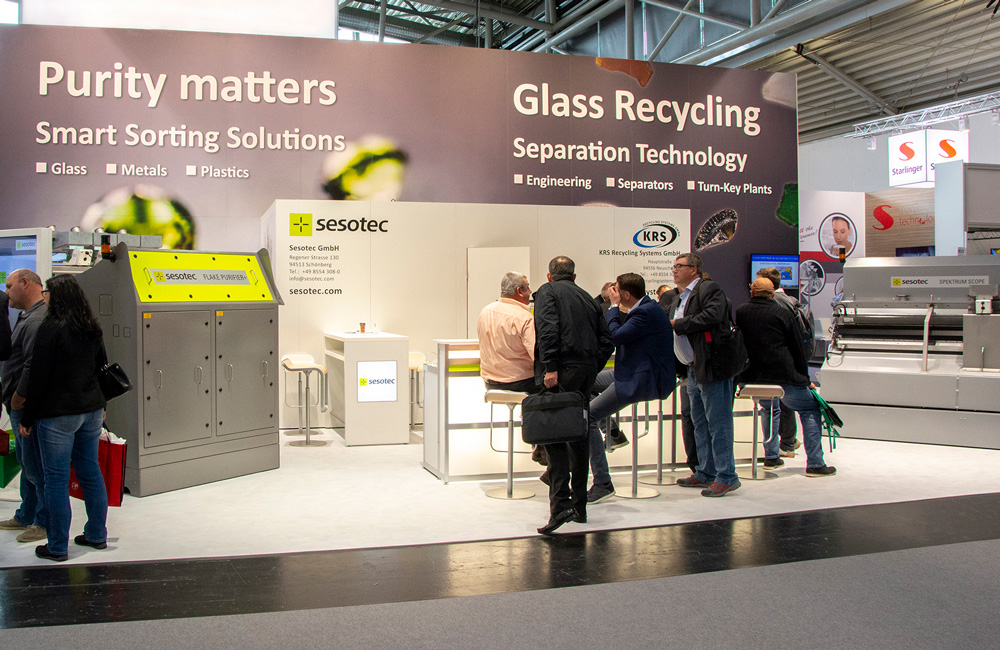

At the Drinktec 2017 trade fair that will be held in Munich from 11 to 15 September 2017, Sesotec GmbH in hall A4, stand 306, for the first time presents itself as a supplier of complete sorting stations for PET flake recycling. Target customers are recycling companies that are looking for a profitable solution for PET flake recycling and wish to have all the components - from air separator through to sorting machine - from one source. The revised FLAKE PURIFIER+ multi-sensor sorting system will be the trade fair highlight.

Sesotec has more than 20 years of experience in the development and production of sorting machines for PET flake recycling, and based on many corresponding inquiries from customers Sesotec now also offers complete PET flake sorting stations. A complete PET flake sorting line from Sesotec offers many advantages, for example less interfaces and contact persons, and uniform operation of all the line components. Mechanical sorting is perfectly matched to sensor sorting, and both ensure optimal performance.

Says Michael Perl, Head of BU Sorting Recycling at Sesotec, about the complete station concept and the new FLAKE PURIFIER+: "Since we received more and more inquiries from customers who wanted to know whether Sesotec also provides complete sorting stations, we decided to satisfy this customer wish. The advantages for customers are obvious: The amount of time and money needed for the coordination of a project is considerably reduced, and the PET flake sorting station operates with maximum profitability. In the modification of the FLAKE PURIFIER multi-sensor sorting system into the new-generation FLAKE PURIFIER+ the wishes of our customers for easier operation and higher material throughput were the decisive factors."