Product inspection has become an indispensable element of responsible food production, an inherent part of any HACCP concept, and an absolute prerequisite of successful IFS certification. Any contamination of food with impurities of any kind may have most serious consequences for a company because according to the product liability law every food producer is liable for contaminations of his products in case a consumer gets harmed by such contaminations. Systems for contaminant inspection are used to prevent such problems. Metal detectors are most useful for the detection of magnetic and non-magnetic metals, but they reach their limits for example in the inspection of aluminium-coated packing materials. Contaminations with glass, ceramics, stones, and similar materials also constitute a serious problem.

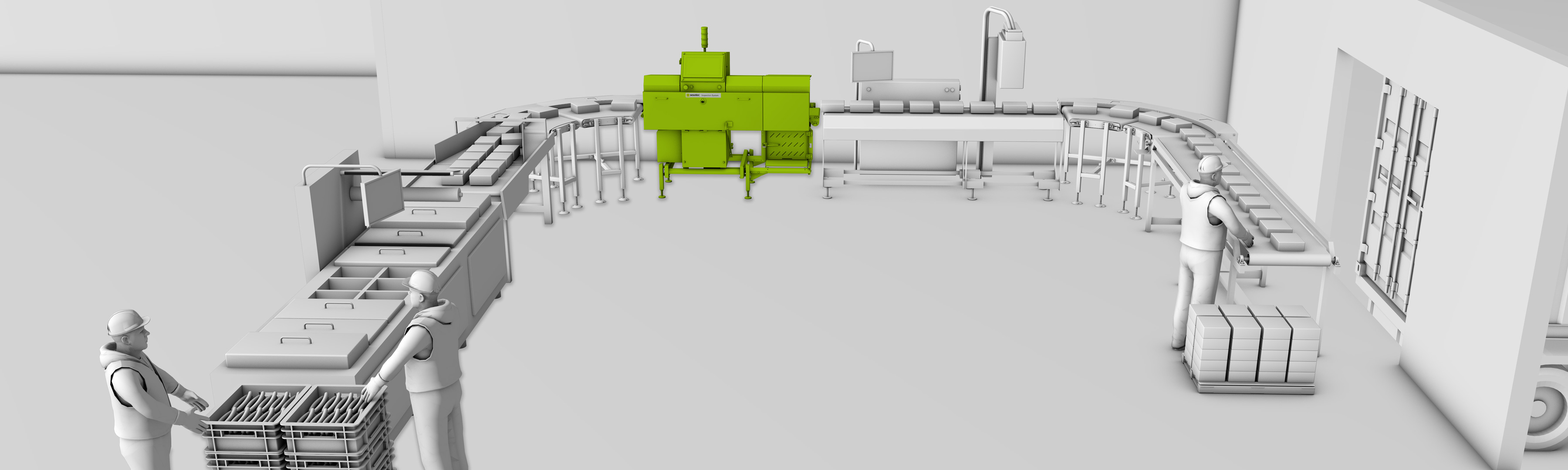

Depending on the density of the inspected object the X-rays are attenuated to a higher (high density) or lower (low density) degree when passing through the product. The detector converts the remaining radiation into an electrical signal, differentiating the density of the inspected object in an image. The higher the density of a material, the darker its representation on the X-ray image, and vice versa. The image processing software detects the contrast differences in the image, highlights the contaminants or the missing products, and outputs a corresponding signal.

This is required by international and national laws. Guidelines support manufacturers in implementing these demands.

Our systems meet all requirements of the common food standards, which means you obtain the necessary certifications with ease and you no longer have any delivery restrictions. Since the food industry never sleeps, more and more retailers only accept goods that have been inspected by an X-ray system.

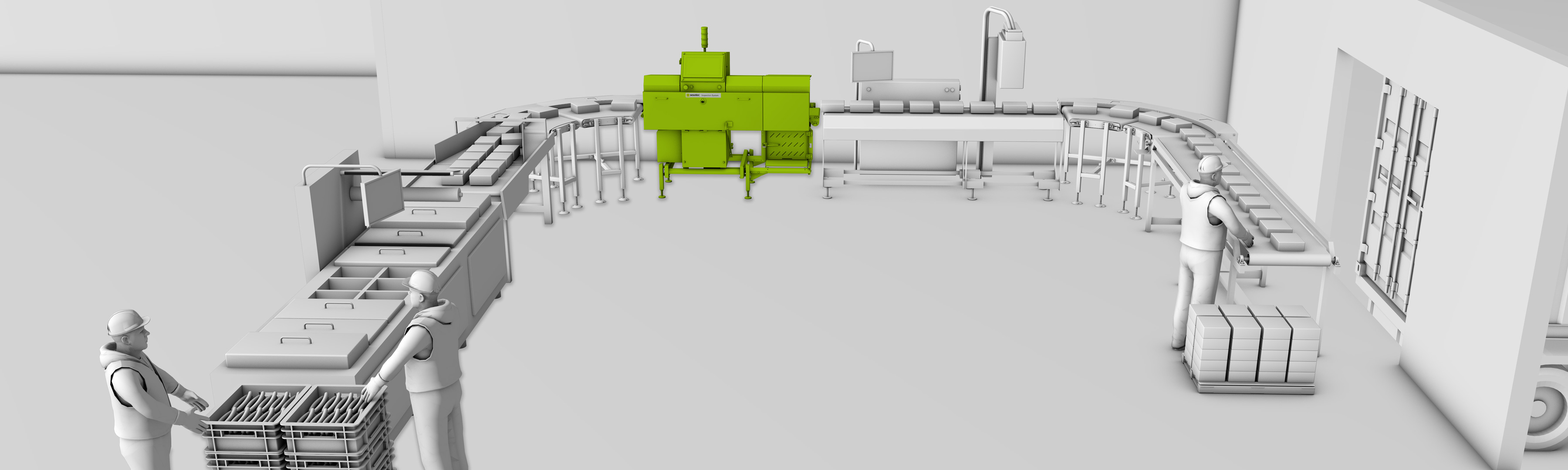

RAYCON is a highly efficient X-ray system which detects any contaminations that absorb X-ray radiation better than the surrounding product due to their density, chemical composition or mechanical dimensions – in short: foreign bodies that are more dense than the actual product.

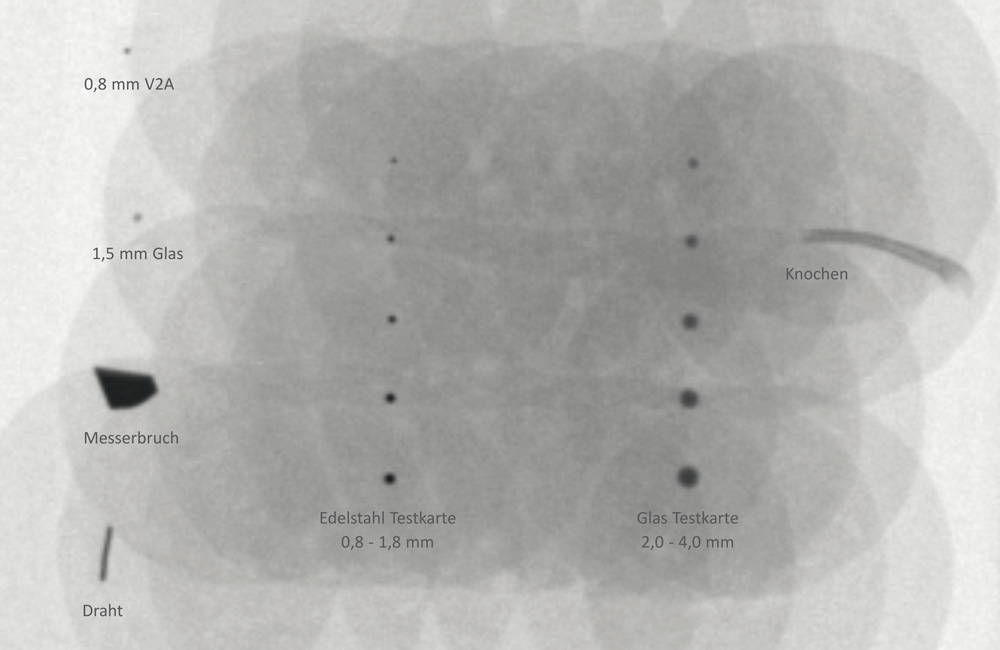

RAYCON being tested

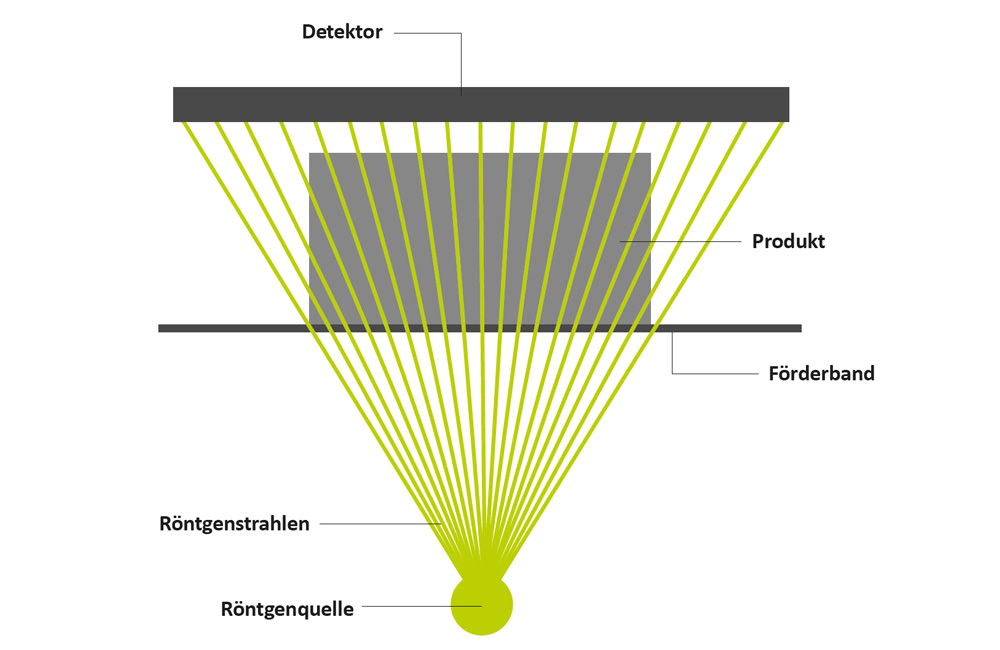

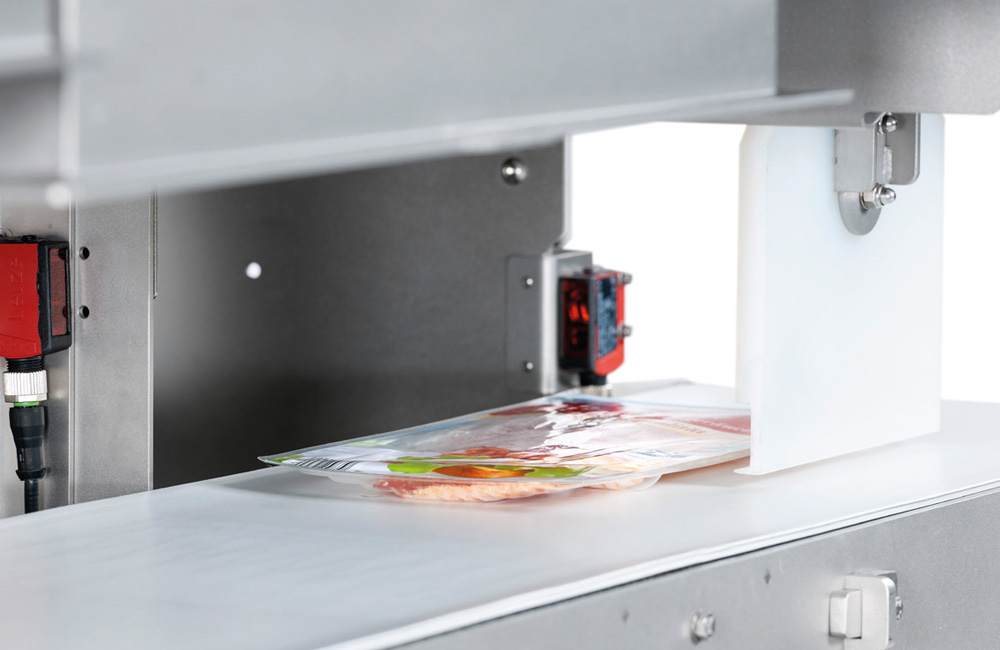

RAYCON specializes in small and medium-sized packaged products. RAYCON‘s performance was tested for the detection of glass, stainless steel, ceramics, Teflon and bone parts using test cards in various products.

With product inspection system RAYCON, any contaminations that absorb X-ray radiation better or worse than the surrounding product due to their density, chemical composition or mechanical dimensions can be detected. A detection power of 50 kV was used for the tests with RAYCON. For small packaged products, the system achieves an inspection performance of 150 - 200 pieces per minute.

RAYCON detects stainless steel, glass, ceramics and Teflon included in the test cards with 100 % detection accuracy. Even bone parts can be reliably detected in flat products.

The selection of your country allows us to offer the optimal content for you.

We have detected the following country based on your IP address:

If this is not correct, please choose your country below.

Aland Islands Albania Andorra Armenia Austria Aserbaidschan Belarus Belgium Bosnia-Herzegovina Bulgaria Croatia Cyprus Czech Republic Denmark Estonia Faroe Islands Finland France Georgia Germany Gibraltar Greece Guernsey Vatican City Hungary Iceland Ireland Isle of Man Italy Jersey Kazakhstan Kosovo Kyrgyzstan Lattvia Liechtenstein Lithuania Luxembourg Macedonia Malta Moldavia Monaco Montenegro Netherlands Norway Poland Portugal Romania Russia San Marino Serbia Slovakia Slovenia Spain Sweden Switzerland Tajikistan Turkey Turkmenistan Ukraina United Kingdom Uzbekistan

Anguilla Antigua & Barbuda Aruba Bahamas Barbados Belize Bermuda Canada Cayman Islands Costa Rica Cuba Curaçao Dominica Dominican Republic El Salvador Greenland Grenada Guadeloupe Guatemala Haiti Honduras Jamaica Martinique Mexico Montserrat Nicaragua Panamá Puerto Rico Saint Barthélemy Saint Kitts and Nevis Saint Lucia Saint Martin (French part) Saint Pierre and Miquelon Saint Vincent and the Grenadines Sint Maarten (Dutch part) Trinidad and Tobago Turks and Caicos Islands USA United States Virgin Islands British Virgin Islands Netherlands Antilles

Afghanistan Bahrain Bangladesh Bhutan British Indian Ocean Territory Cambodia China Taiwan India Indonesia Iran Iraq Israel Japan Jordan North Korea South Korea Kuwait Laos Lebanon Macao Malaysia Maldives Mongolia Myanmar Nepal Oman Pakistan Palestinian Territory, Occupied Philippines Qatar Saudi Arabia Singapore Sri Lanka Syria Taiwan Thailand Timor-Leste United Arab Emirates Vietnam Yemen

Algeria Angola Benin Botswana Burkina Faso Burundi Cameroon Cape Verde Central African Republic Chad Comoros Republic of the Congo Democratic Republic of the Congo Ivory Coast Djibouti Egypt Equatorial Guinea Eritrea Ethiopia Gabon Gambia Ghana Guinea Guinea-Bissau Kenya Lesotho Liberia Libya Madagascar Malawi Mali Morocco Mauritania Mauritius Mayotte Mozambique Namibia Niger Nigeria Reunion Rwanda Saint Helena, Ascension and Tristan da Cunha Sao Tome and Principe Senegal Seychelles Sierra Leone Somalia South Africa South Sudan Sudan Swaziland Tanzania Togo Tunesia Uganda Western Sahara Zambia Zimbabwe

American Samoa Australia Brunei Christmas Island Cocos (Keeling) Islands Cook Islands Fidschi French Polynesia Guam Heard Island and McDonald Islands Kiribati Marshall Islands Micronesia Nauru New Caledonia New Zealand Niue Norfolk Island Palau Papua New Guinea Pitcairn Samoa Solomon Islands Tokelau Tonga Tuvalu Vanuatu Wallis and Futuna Northern Mariana Islands