Circular Economy

Feb 19, 2020 |

Circular economy – it needs to be profitable

In 2015, the EU Commission adopted an action plan for the circular economy encompassing 54 measures. In March of 2019, it delivered a positive summary of the progress to date: “The principles of the circular economy have found their way into production, consumption, water management, the food industry, the management of specific waste streams and especially in plastics,” explained Frans Timmermanns, First Vice President of the EU Commission. The numbers back it up. In 2016 alone, EUR 147 billion of added value was generated from circular economy activities such as repairs, re-use or recycling, with investments totalling EUR 17.5 billion. One element of the circular economy in Europe is the EU Plastics Strategy. Among other things, it envisages that all plastic packaging in the EU market will be recyclable by 2030.

Challenges for recyclers

However, there is still plenty to do before this becomes

a reality and the cycle is closed. For example, prices for recycled and new

materials are currently fluctuating. This represents a challenge for recyclers,

because if the price for recycled materials is higher than the price for new

materials, demand for them will fall.

At the same time, the price for recycled materials depends on a number of factors. First of all, there is the amount of available material, which in turn is linked to collection and disposal systems. It is also measured against the respective cost of the sorting and treatment process, as the degree of purity required of the plastic varies depending on its target application. In some cases, significant quantities of water and energy need to be consumed in the cleaning and sorting process. If its profitability is called into question at this point in the cycle, the entire circular economy will start to falter.

Hurdles for plastics manufacturers and processors

Plastics manufacturers and processors face a similar situation. Their profitability is also dependent on the available quantity, quality and price of the recycled material. Manufacturers and processors need planning reliability with regard to all three components. Without a sufficient quantity, for example, they face the threat of loss of production, and if the raw material is of poor quality, they risk an inferior end product. The material used is often contaminated with pieces of metal, which results in costly damage to machinery, process disruptions and stoppages. Not least, their profits will be squeezed if purchase prices are too high.

Lots of potential

Calculation scenarios of “Der Grüne Punkt” (The

Green Dot), Germany’s market leader for dual systems, have shown that there is

considerable value added potential for recycled materials based solely on a

more extensive use of the current leading technology without any substantial

technological developments. For example, the market volume for recycled

plastics in Germany could increase by up to 119 percent, from EUR 189 million

in 2014 to EUR 414 million in 2030. If the framework conditions and demand

trends improve, a market volume of as much as EUR 1.04 billion may be possible

for 2030.

A further point that confirms this potential is that global demand for plastic is rising. At the same time, increasing demand may result in a difficult supply situation with long delivery times for new materials. In this case, secondary raw materials may supplement the primary materials and form a supply market which is largely independent of the volatilities of new materials in respect of supply and price.

From “nice to have” to competitive advantage

Politicians can also have a positive impact on the potentials inherent

in recycling by enacting measures which concern packaging laws and set fixed

recycling rates, for example. Ambitious targets have already been set with the

EU Plastics Strategy mentioned at the start of this article.

The attitude of companies concerning the use of recycled material also plays an important role. A lot of companies have started to rethink their approach. The CO2 footprint – the total carbon dioxide emissions generated directly or indirectly in the manufacturing process or whole life cycle of products – is attracting increasing attention. A positive CO2 balance is becoming part of a sustainable product strategy and in some cases a competitive advantage. The recyclability of materials can be taken into account in the product and packaging development stage. If this is communicated clearly to the consumer, it will in turn increase the acceptance and demand for products made from recycled materials – in part, because they are doing their part to protect the environment.

For the sake of the environment

The environment benefits greatly from a high

recycling potential and a closed plastics cycle. The reason being that production

of plastics products currently mainly makes use of primary plastics made out of

crude oil. According to the German Association for Secondary Raw Materials and

Waste (bvse), plastics recycling reduces the demand for crude oil in two ways –

through saving new plastics on the one hand, and saving energy on the other. In

plastics recycling, only 33 to 50 percent of the energy needed to manufacture

new materials is consumed. Furthermore, the CO2

saving is considerable. According to the association, every tonne of recycled

plastic used instead of comparable new materials, prevents between 1.45 and

3.22 tonnes of climate-relevant greenhouse gases.

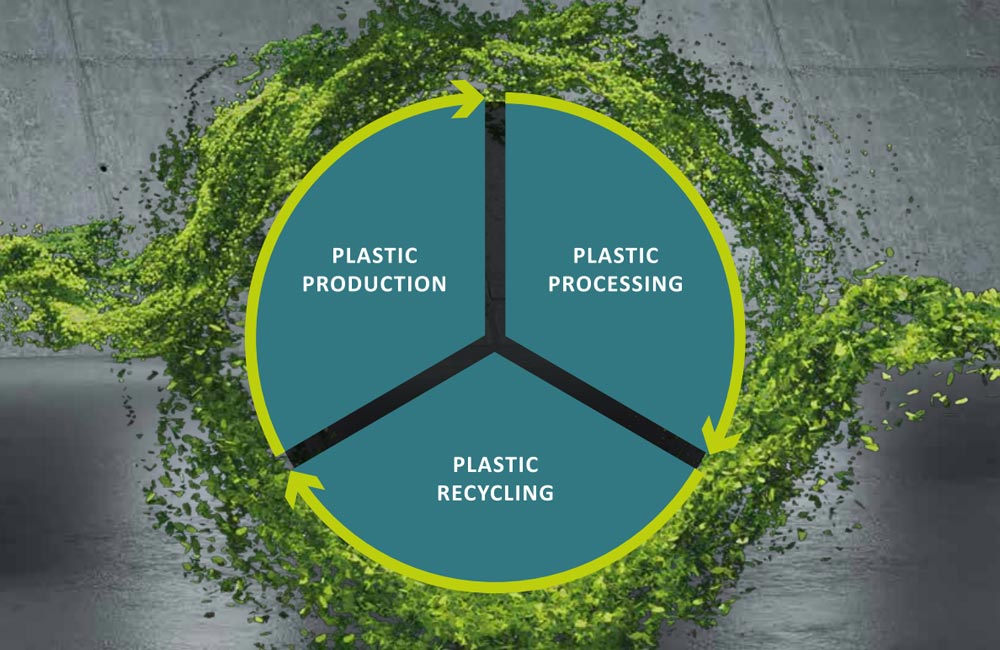

About Sesotec

As a partner to the plastics industry, Sesotec

provides a variety of solutions designed to meet the needs of recyclers,

plastics manufacturers and plastics processors. Sesotec helps ensure product

purity through sensor-based material analysis systems, sorting systems, metal

separators and services. The result? Guaranteed efficiency and profitability

for the preparation, production and processing of plastics.