At IFFA 2019, Sesotec will present solutions for food inspection in accordance with HACCP.

Our highlights at this year’s IFFA:

"X-ray inspection for the future"

Design study for X-ray inspection of unpackaged meat products

Inspection solutions for packaged meat products

Our new Lifetime Warranty package for X-ray machines

Looking forward to the event? You can find out more about Sesotec at IFFA 2019 here.

Make

an appointment to talk to us at IFFA now

and get a free entry voucher!

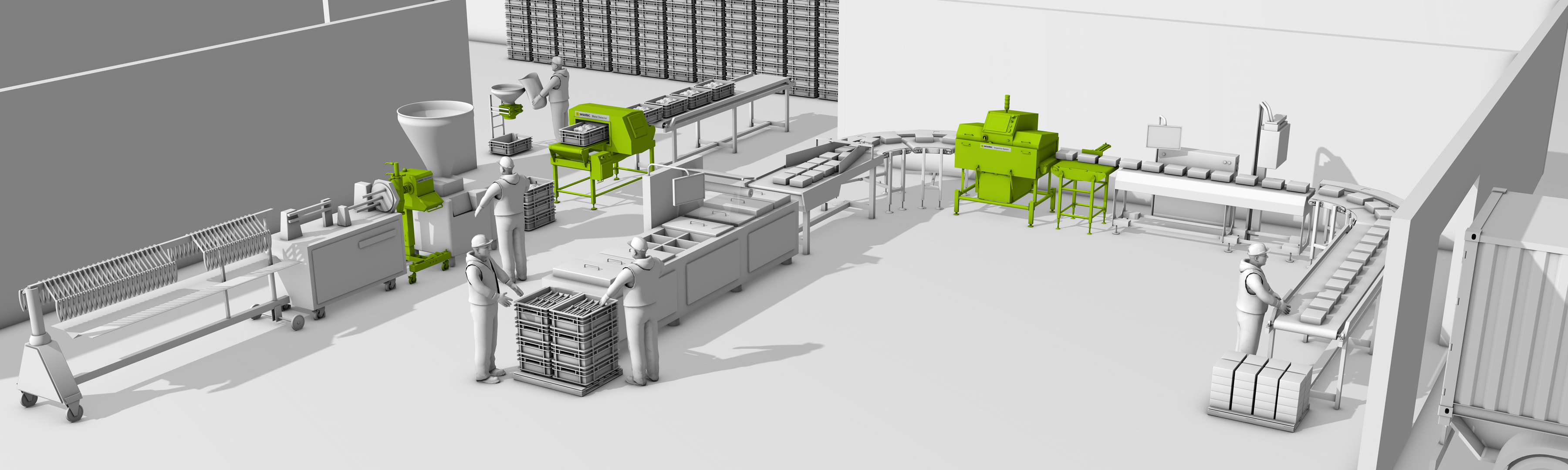

Design

study on X-ray technology for unpackaged meat products:

Join us in redefining the future!

Seize

this opportunity to look at current issues and trends with us. To illustrate

what the future holds in store, we have developed a transparent prototype of an

X-ray machine for unpackaged meat products which we can use to explore details

and understand your requirements for future solutions.

Among other things, we would like to discuss the following issues with you:

Compliance with food guidelines

Options for use

Design

We look forward to exiting discussions with you!

"Detection of plastics with dual-energy technology"

Expert lecture by Uli Hurzlmeier, Product Manager

X-ray, Sesotec GmbH

Tuesday, May 7, 2019, 3:40 pm - 4:00 pm

IFFA Forum (Hall 11.1 C40

)

SAVE THE DATE!

At IFFA, we will present the VARICON+ metal

detection system, featuring the integrated INTUITY metal detection coil for

inspecting packaged meat products. The system detects all metal contaminants, such

as steel, stainless steel and aluminium – even those completely hidden inside

the product. It is mainly used to inspect outgoing goods or to perform inline

inspection during packaging, weighing and labelling.

Your benefits:

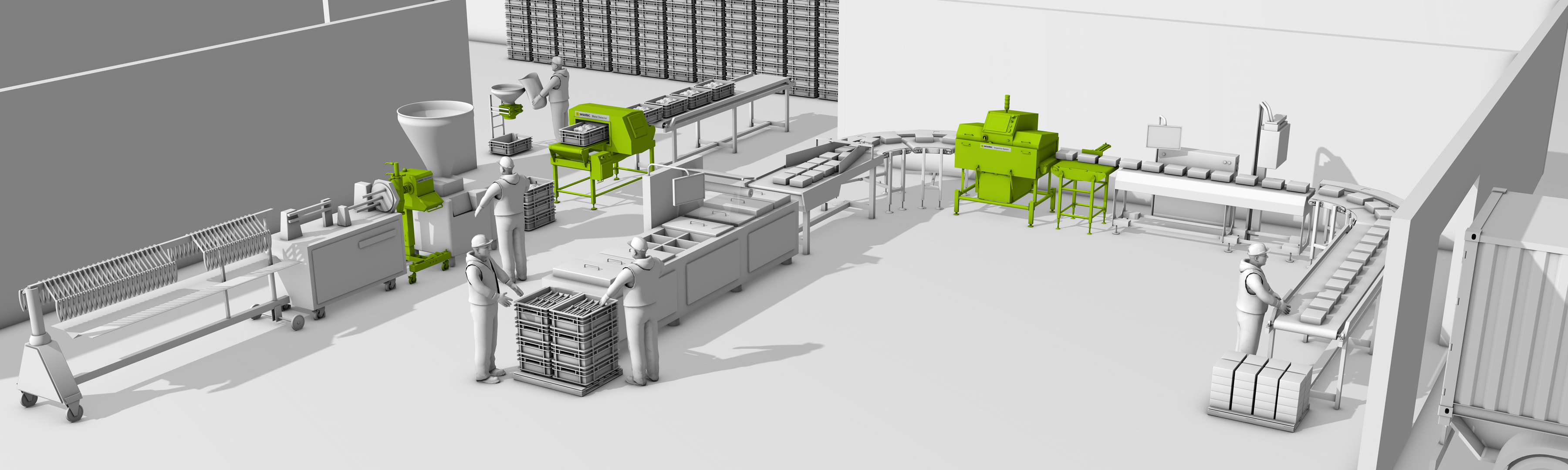

The RAYCON EX1 system is part of Sesotec's product portfolio and an easy and affordable

introduction to X-ray inspection. In particular, the system is suitable for end-of-line inspection of

packaged products up to 200 mm in width and 120 mm in height.

With a short installation length of only 800 mm and an Ethernet connection, the RAYCON EX1 can be easily integrated into existing packaging lines. With the help of low-energy X-ray technology, the system makes a long-term contribution to efficient and environmentally friendly use while enabling high detection accuracy for contaminants such as stainless steel, glass or stones larger than 0.6 mm. The system is easy to integrate, operate, maintain and clean.

Easy installation.

Easy operation.

Easy maintenance.

Easy decision.

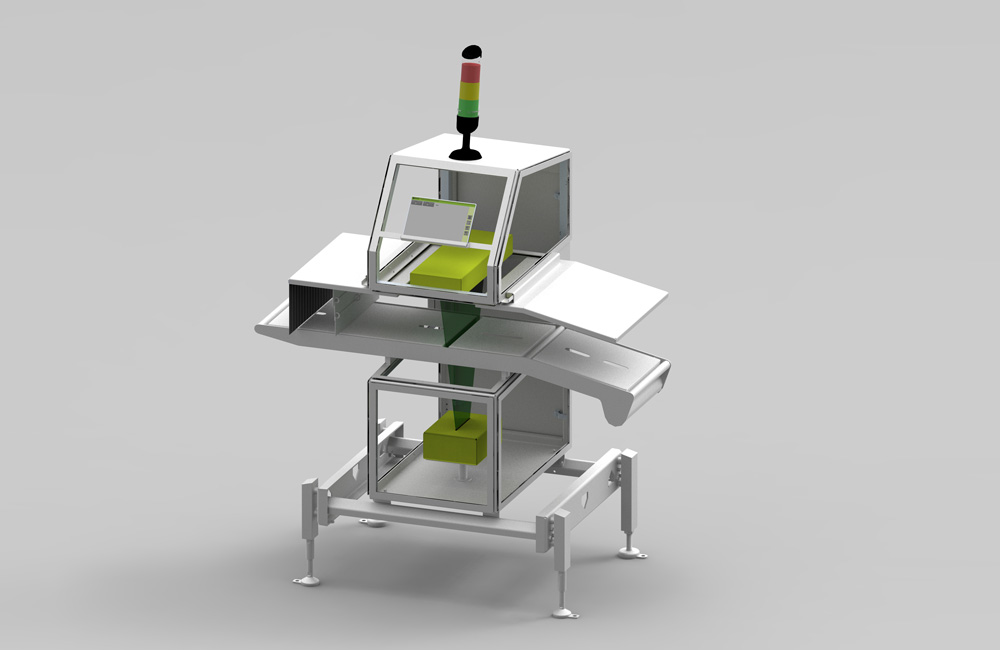

At IFFA, our service staff will present the new Lifetime Warranty package for X-ray systems to you. This service package offers you a lifetime warranty extension on X-ray tubes and detectors!

The benefit for you: you can continue production with maximum value creation and retain cost control over the entire lifetime.

Make an appointment for a personal meeting at IFFA and receive a free entry voucher.