在汽车轮胎和其他橡胶制品制造过程中,如果有金属碎片意外进入生产流程,代价将会非常巨大。 可能造成的风险包括设备损坏或生产停工。我们的金属检测系统能够对此类污染物进行有效检测,能将此类风险降至最低。

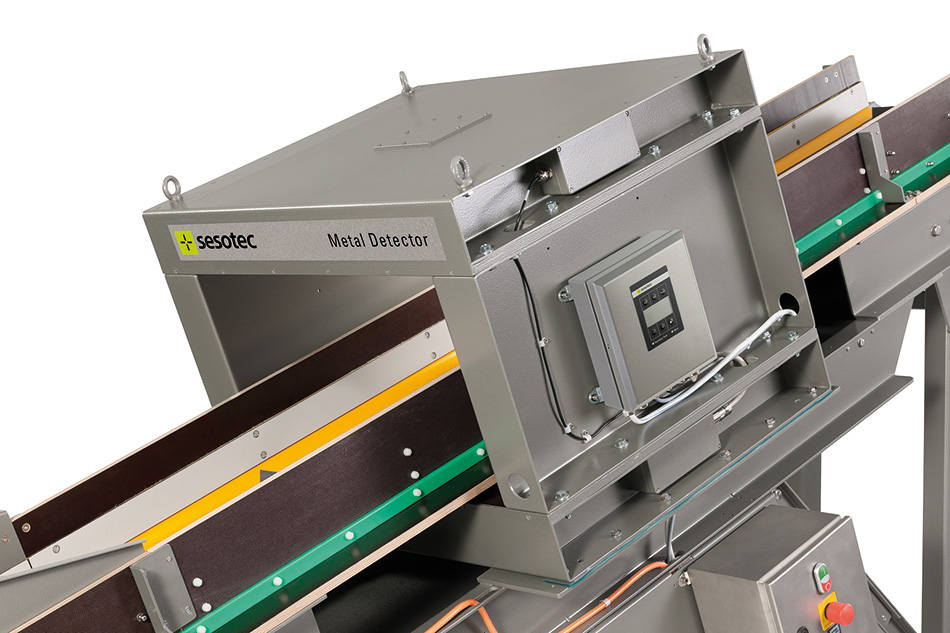

Sesotec一直专注于各个行业内污染物检测系统的研发,拥有40多年轮胎和橡胶行业检测经验。

我们提供包括金属检测器和除铁器在内的全套领先技术,能可靠检测并剔除各类污染物,还可对磁性/非磁性、涂镀、上漆、散件或嵌件类铝、铜或黄铜等黑色金属、不锈钢及有色金属物进行检测。

了解更多

为什么污染物检测在轮胎和其他橡胶制品生产中非常重要?

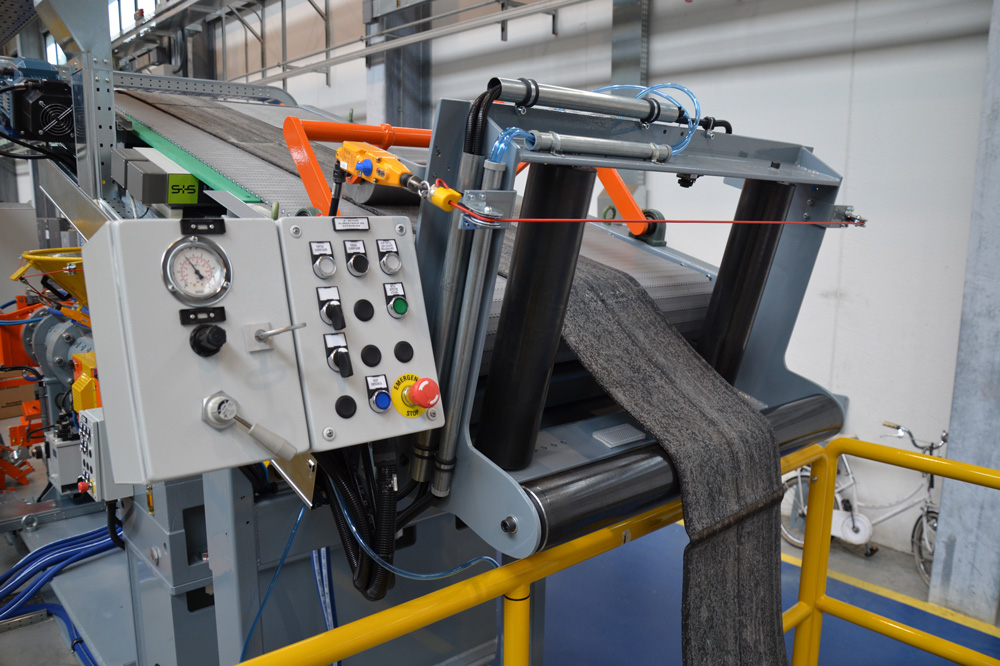

在轮胎和其他橡胶制品生产中,设备保护是一大关键。高利用率、自动化、充分协调的工艺步骤是打造橡胶和轮胎行业经济型生产线的基础,所以,避免生产设备损坏和停机故障的发生至关重要。无论是在供应商端还是在内部生产过程中,加工材料内的金属物质混入均可导致上述事件的发生,并引起挤出机阻塞、压延机辊出现痕印而导致最终产品(比如轮胎)变形,或压痕,轮胎耐用性受损等问题,并使消费者的安全受到威胁。因此,金属污染物检测和剔除设备成为轮胎和其他橡胶制品生产的标配之一。

轮胎和橡胶行业中的污染物检测面临哪些挑战?

不同的橡胶配方包含不同数量的炭黑、氧化物和活化剂,因此,在固有导电性上会有很大的差别。另外,不同机器的运行环境以及多数情况下输送机运行速度极慢等其他因素,也使得难以在避免误报警的情况下,有效进行金属检测。

Sesotec金属检测器配备最先进的检测技术和极高的扫描灵敏度,并可通过保存不同橡胶配方的工作参数来主动阻止环境干扰,并可补偿材料的固有导电性。多频技术还可以轻松检测具有高固有导电性的复合物配方。

了解更多信息或咨询建议? 请联系我们

轮胎和橡胶生产存在哪些污染物?

各类金属都是橡胶和轮胎行业中最常见的污染物。可能的来源包括:

Sesotec检测系统在橡胶和轮胎制造中的应用

最常见应用包括:

我们的检测系统和设备适用于胶和轮胎制造的各道生产工序,并可根据具体需求,为您定制最具个性化的产品解决方案。

Separately purchased recyclate often contains various different

polymers as well as metal contaminants such as aluminum, brass, and

stainless steel. Learn in our Case Study how Sitraplas has solved this

problem.

SITRAPLAS GmbH is a producer of high-performance engineering plastic compounds. Unplanned downtime is a nightmare for every company, but especially for continuous production facilities. When metal separators are networked with plastic processing machines, the flow of information between machines can be monitored.

To avoid any metal in the powder, CIPSA wanted to inspect the PVC compounds before they enter the pelletizer. This was to protect the extruder screw from damage and avoid expensive production stops.

Splitable metal detector for installation on conveyor belts and material chutes

Compact metal detection system with conveyor belt for the inspection of piece goods

Inline magnet for protecting extruders, injection moulding and blow moulding machinery