request

a non-binding consultation now

What

requirements do resin and compound manufacturers

have for metal separators?

Compound

manufacturers must be able to reliably detect even the smallest metal parts to

prevent machine damage and metal inclusions in the granulate. Metal separators

must therefore have high detection accuracy.

Fast cleaning for colour and material changes

With frequent colour and material changes, it is important that the metal separator is reliably cleaned to ensure the quality of subsequent batches. In addition, the cleaning process must be as quick and easy as possible to keep plant downtimes to a minimum.

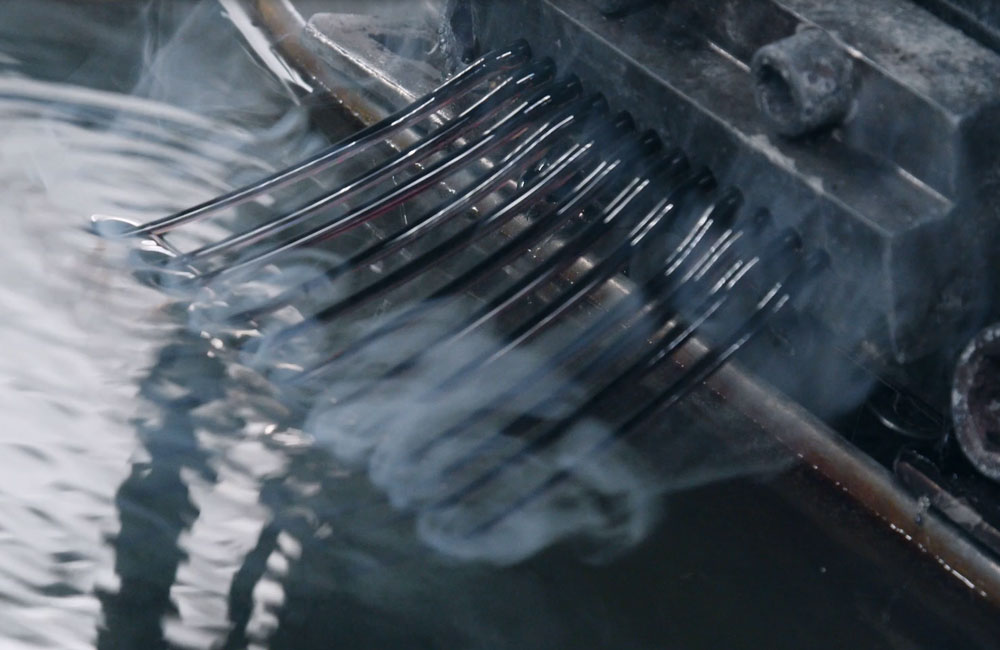

When

abrasive materials are used, parts in contact with the product are usually

subject to high wear. For this reason, metal separators for compound

manufacturers must be specially designed for this requirement and be as wear-resistant

as possible.

...this

is exactly what the new RAPID PRO-SENSE 6 offers

The

RAPID PRO-SENSE 6 detects and separates the smallest metal parts. This enables

you to achieve a consistently high product quality and avoid complaints due to

metal inclusions. An integrated logbook function also ensures the traceability

of batches.

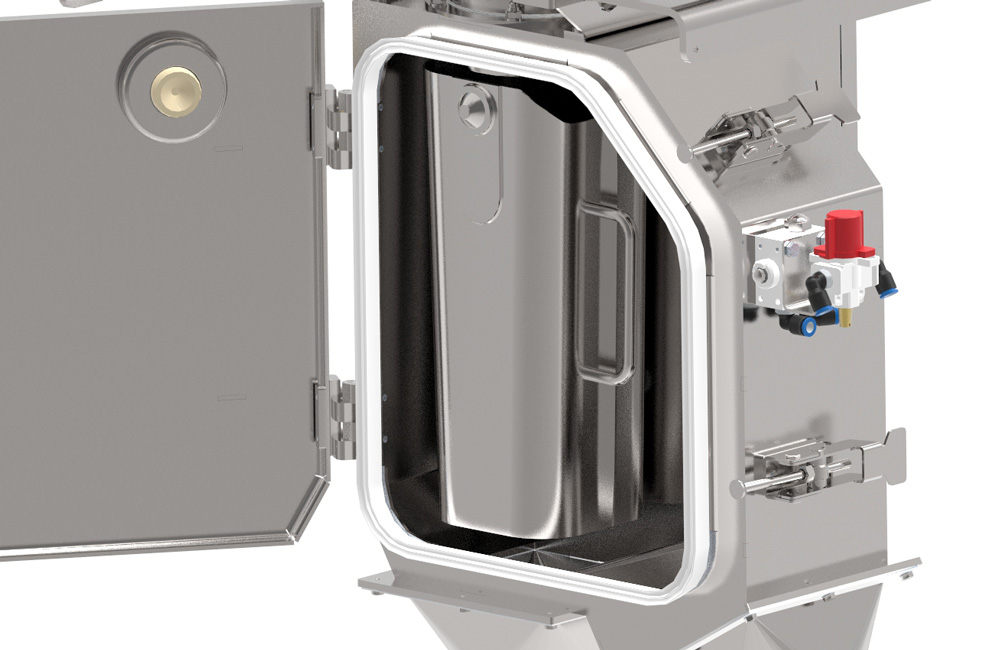

The

RAPID PRO-SENSE 6 can be cleaned easily, quickly and without tools. And that

even in complex installation situations. This allows you to change colours and

materials quickly. Optionally, the RAPID PRO-SENSE 6 also offers integrated

washing nozzles for automatic cleaning.

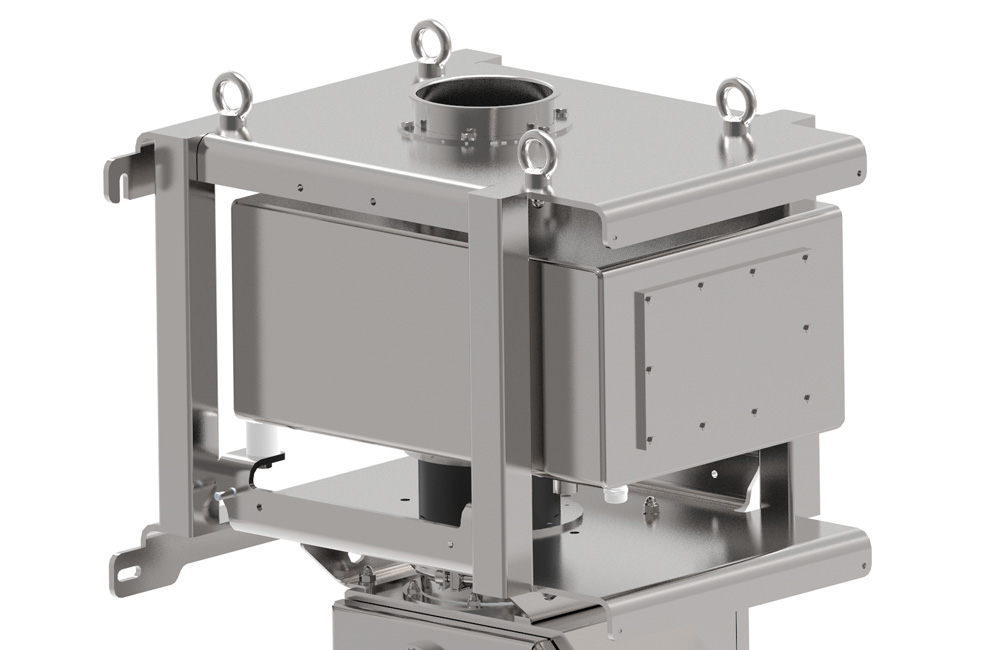

Short

cleaning times increase the up-time, reduce personnel costs, increase line

availability and make your plant more economical. With the optional washing

nozzles, you also reduce manual effort. A special, wear-resistant design

prevents damage to parts in contact with the product, thus saving costs for

spare parts.

The

detection unit of the RAPID PRO-SENSE 6 works extremely accurately and detects

even the smallest metallic contaminants. This ensures your product quality and

protects you from complaints due to metal inclusions.

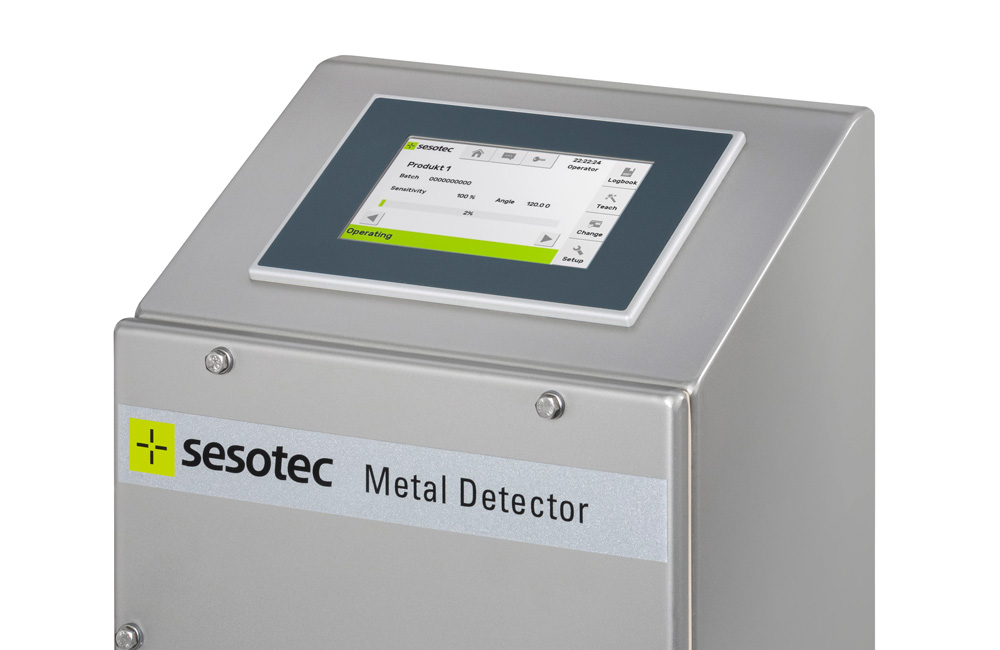

The

brand new control unit GENIUS ONE is part of the standard equipment of the

RAPID PRO-SENSE 6. With a 5'' colour touch screen, it is intuitive to operate

and offers an integrated logbook function for tracing product batches. An

Ethernet interface, also included as standard, makes the unit "Industry

4.0-ready".

The selection of your country allows us to offer the optimal content for you.

We have detected the following country based on your IP address:

If this is not correct, please choose your country below.

Aland Islands Albania Andorra Armenia Austria Aserbaidschan Belarus Belgium Bosnia-Herzegovina Bulgaria Croatia Cyprus Czech Republic Denmark Estonia Faroe Islands Finland France Georgia Germany Gibraltar Greece Guernsey Vatican City Hungary Iceland Ireland Isle of Man Italy Jersey Kazakhstan Kosovo Kyrgyzstan Lattvia Liechtenstein Lithuania Luxembourg Macedonia Malta Moldavia Monaco Montenegro Netherlands Norway Poland Portugal Romania Russia San Marino Serbia Slovakia Slovenia Spain Sweden Switzerland Tajikistan Turkey Turkmenistan Ukraina United Kingdom Uzbekistan

Anguilla Antigua & Barbuda Aruba Bahamas Barbados Belize Bermuda Canada Cayman Islands Costa Rica Cuba Curaçao Dominica Dominican Republic El Salvador Greenland Grenada Guadeloupe Guatemala Haiti Honduras Jamaica Martinique Mexico Montserrat Nicaragua Panamá Puerto Rico Saint Barthélemy Saint Kitts and Nevis Saint Lucia Saint Martin (French part) Saint Pierre and Miquelon Saint Vincent and the Grenadines Sint Maarten (Dutch part) Trinidad and Tobago Turks and Caicos Islands USA United States Virgin Islands British Virgin Islands Netherlands Antilles

Afghanistan Bahrain Bangladesh Bhutan British Indian Ocean Territory Cambodia China Taiwan India Indonesia Iran Iraq Israel Japan Jordan North Korea South Korea Kuwait Laos Lebanon Macao Malaysia Maldives Mongolia Myanmar Nepal Oman Pakistan Palestinian Territory, Occupied Philippines Qatar Saudi Arabia Singapore Sri Lanka Syria Taiwan Thailand Timor-Leste United Arab Emirates Vietnam Yemen

Algeria Angola Benin Botswana Burkina Faso Burundi Cameroon Cape Verde Central African Republic Chad Comoros Republic of the Congo Democratic Republic of the Congo Ivory Coast Djibouti Egypt Equatorial Guinea Eritrea Ethiopia Gabon Gambia Ghana Guinea Guinea-Bissau Kenya Lesotho Liberia Libya Madagascar Malawi Mali Morocco Mauritania Mauritius Mayotte Mozambique Namibia Niger Nigeria Reunion Rwanda Saint Helena, Ascension and Tristan da Cunha Sao Tome and Principe Senegal Seychelles Sierra Leone Somalia South Africa South Sudan Sudan Swaziland Tanzania Togo Tunesia Uganda Western Sahara Zambia Zimbabwe

American Samoa Australia Brunei Christmas Island Cocos (Keeling) Islands Cook Islands Fidschi French Polynesia Guam Heard Island and McDonald Islands Kiribati Marshall Islands Micronesia Nauru New Caledonia New Zealand Niue Norfolk Island Palau Papua New Guinea Pitcairn Samoa Solomon Islands Tokelau Tonga Tuvalu Vanuatu Wallis and Futuna Northern Mariana Islands