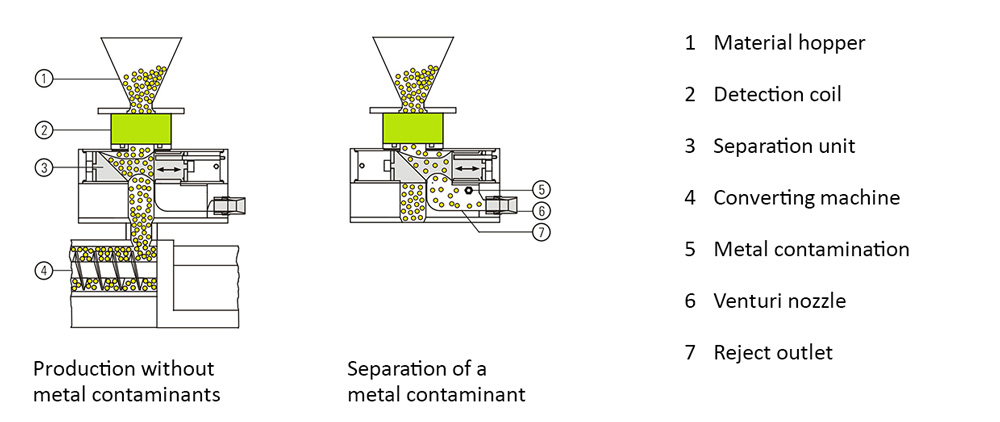

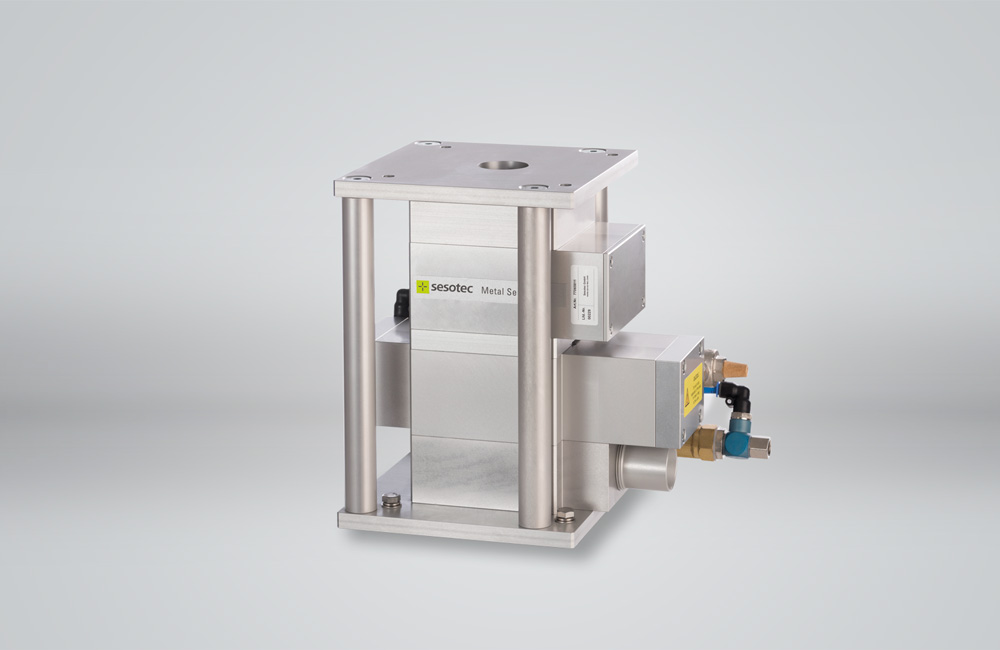

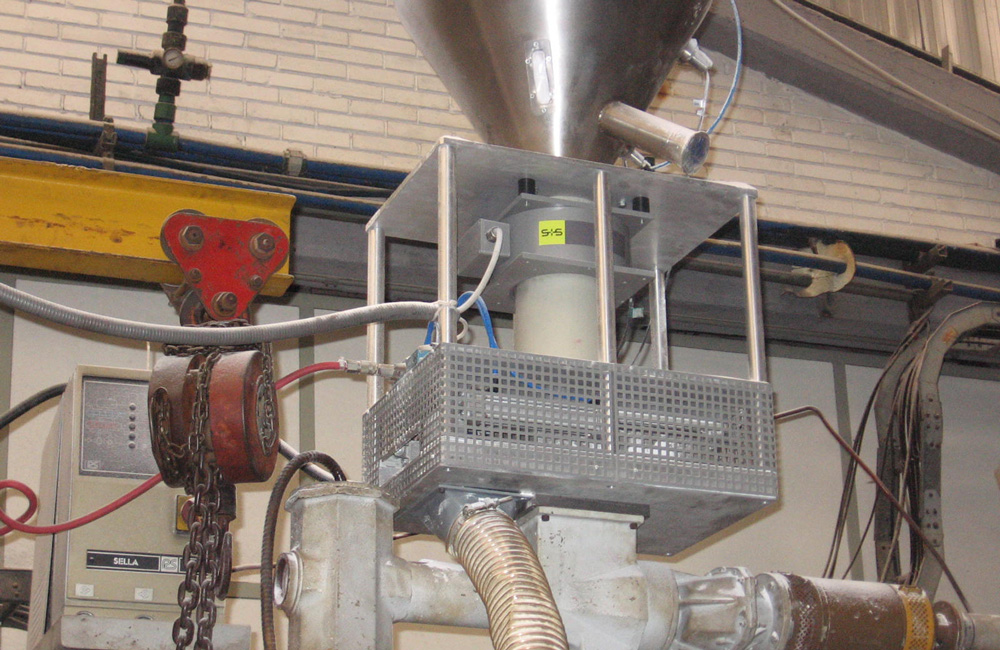

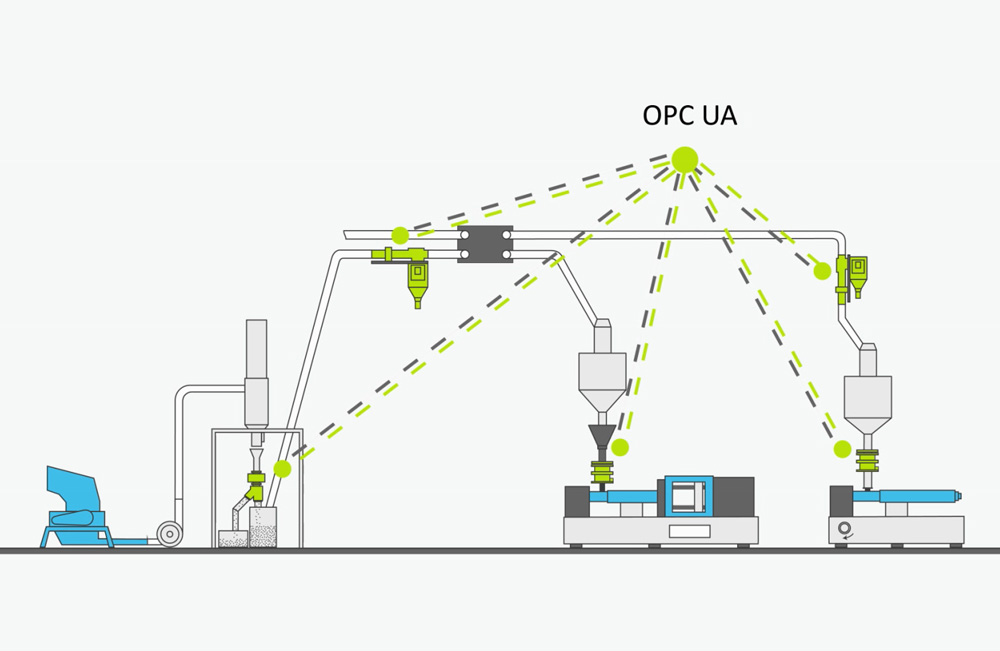

Metal detection systems for material columns

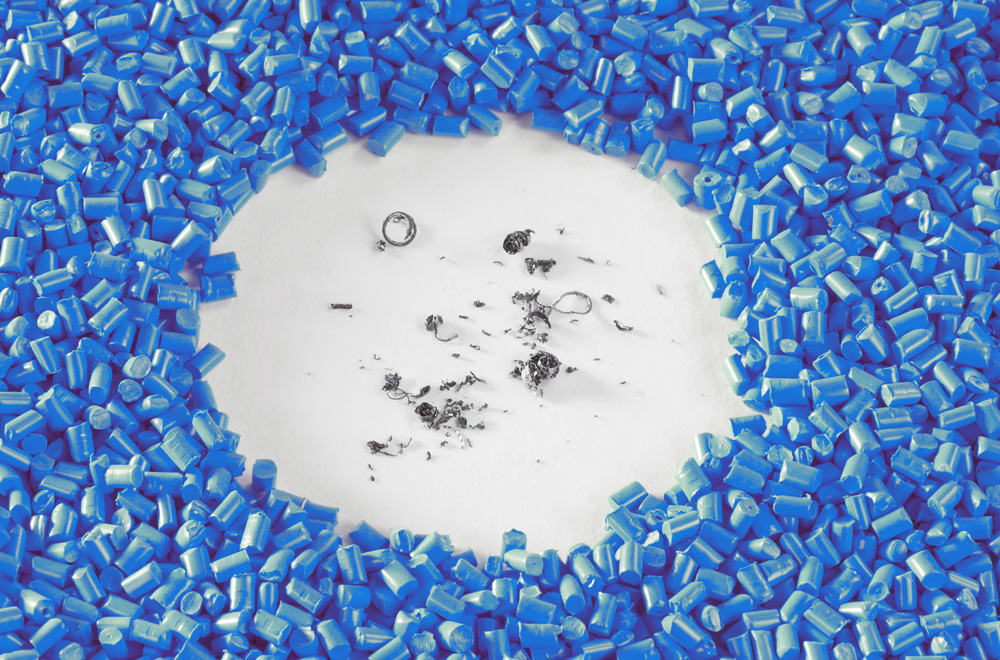

Minute metal particles in polymer melt can lead to costly breakdowns during injection moulding, extrusion and blow moulding. The risk is further increasing with the growing practice in the plastics-processing and recycling industries of processing regranulate and regrind. Our metal separators efficiently and reliably remove contaminants right at the material inlet above the machine.

Our metal detectors are installed directly before injection-moulding

machines, extruders and blow-moulding machines to inspect slow-moving or

standing material columns. Positioning our metal detectors there enables you to

remove all magnetic and non-magnetic metals − even if they are embedded in the

product − while ensuring minimal loss of material. More information on how

Sesotec metal detectors and separators work is available

here.